Titanate-based lead-free silver electrode paste, preparation method and use method thereof

An electrode paste, lead silver technology, which is applied to conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc. Achieve the effect of high Q value, good solderability and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

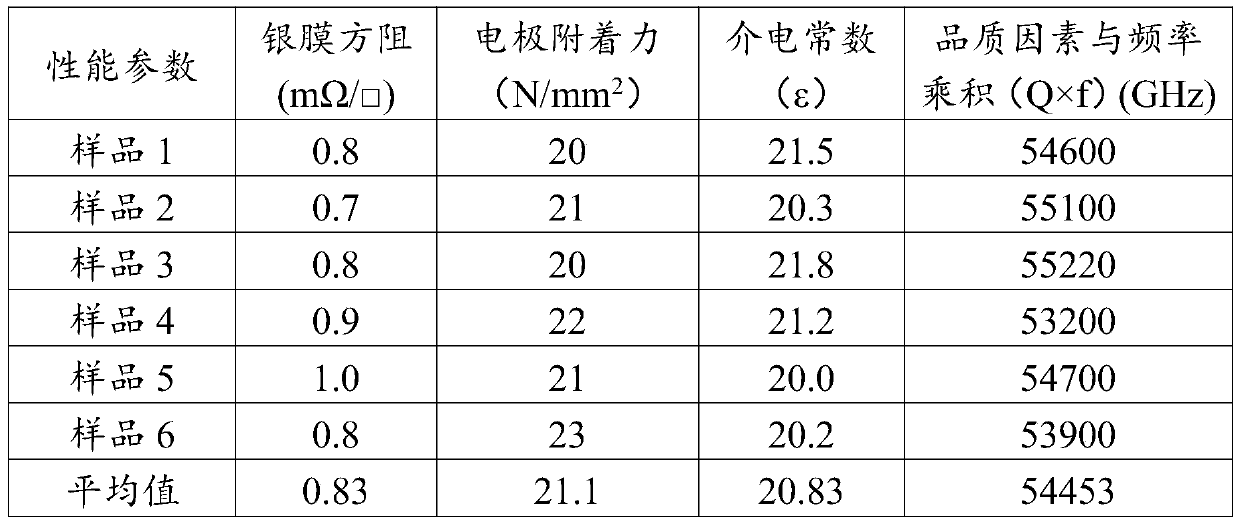

Examples

Embodiment 1

[0046] A titanate-based 5G ceramic filter environment-friendly silver electrode paste (preparation 100g), its production process is as follows:

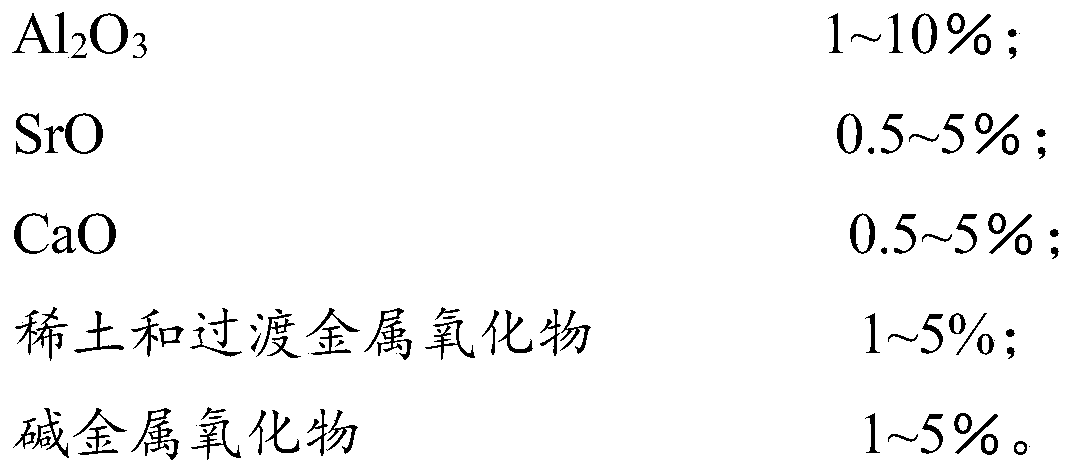

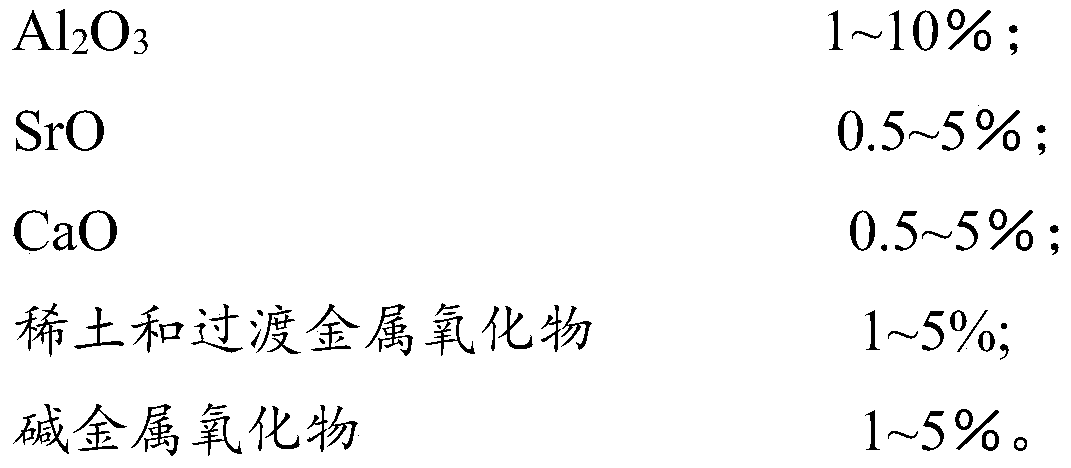

[0047] (1) Glass powder formula (preparation 100g): V 2 o 5 10g, B 2 o 3 20g, SiO 2 5g, ZnO 10g, Bi 2 o 3 38g,TiO 2 5g, Al 2 o 3 3g, SrO 1g, CaO 1g, Sm 2 o 3 1g, Nd 2 o 3 1g, CuO 1g, Na 2 O 2g, Li 2 O 2g;

[0048] (2) Glass melting and ball milling process: Mix the raw material formula in step (1) evenly and melt at 1200°C for 60 minutes, then quench and ball mill to particle size D 50 Less than 3μm, get lead-free glass powder;

[0049] (3) Highly active metal silver powder is spherical silver powder made by wet chemical silver nitrate reduction method, and the particle size of silver powder is D 50 = 1.6 μm;

[0050] (4) The organic vehicle is weighed according to the mass ratio of resin and solvent of 20:80, boiled at 120°C for 2 hours, and then filtered to obtain the organic vehicle;

[0051] (5) Slurry p...

Embodiment 2

[0068] A titanate-based 5G ceramic filter environment-friendly silver electrode paste (preparation 100g), its production process is as follows:

[0069] (1) Glass powder formula (preparation 100g): V 2 o 5 15g, B 2 o 3 25g, SiO 2 15g, ZnO 15g, Bi 2 o 3 10g,TiO 2 8g, Al 2 o 3 2g, SrO 1g, CaO 2g, Sm 2 o 3 1g, Nd 2 o 3 1g, CuO 1g, Na 2 O 2g, K 2 O 2g;

[0070] (2) Glass melting and ball milling process: Mix the raw material formula in step (1) evenly and melt at 1250°C for 60 minutes, then quench and ball mill to particle size D 50 Less than 3μm, get lead-free glass powder;

[0071] (3) Highly active metal silver powder is spherical silver powder made by wet chemical silver nitrate reduction method, and the particle size of silver powder is D 50 = 1.0 μm;

[0072] (4) The organic vehicle is weighed according to the mass ratio of resin and solvent of 15:85, boiled at 120°C for 2 hours, and then filtered to obtain the organic vehicle;

[0073] (5) Slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com