Dispersed azo dye mixture and application thereof

A technology of azo dyes and mixtures, applied in the field of dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

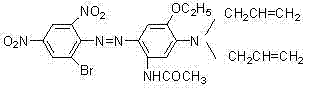

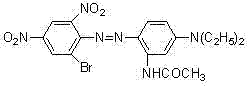

Method used

Image

Examples

Embodiment 1

[0063] (1) 16.7 grams of dye A with general formula (Ia), 11.9 grams of dye B with general formula (IIg) and 15.3 grams of dye C with general formula (IIIa) were mixed with 500 milliliters of water and 50 grams of lignosulfonate The sodium bicarbonate was ground together in a sand mill for 3 hours, and then spray-dried (inlet temperature 130°C, outlet temperature 60°C) to obtain dye mixture 1. The resulting powder dye (about 100 g) was easily dispersed in water.

[0064] (2) 0.4 g of the above-prepared powder dye mixture 1 was dyed with 10 g of polyester textile material by conventional HT printing and dyeing method at pH = 4.5 and 130 ° C for about 45 minutes, washed, rinsed and dried to obtain a fairly good The fastness performance of the dyeing sample 1 of red brilliant navy blue.

Embodiment 2

[0066] 1) Condensation of 24 grams of dye A of general formula (Ib), 22 grams of dye B of general formula (IIe) and 7 grams of dye C of general formula (IIIa) with 300 grams of water and 47 grams of naphthalenesulfonic acid formaldehyde Grinding together, according to the preparation method of Example 1 and drying to obtain dye mixture 2.

[0067] (2) According to the dyeing method of Example 1, when 0.4 g of this dye mixture was used to dye polyester fiber fabric, dyeing sample 2 with reddish brilliant (bloomy) black was obtained.

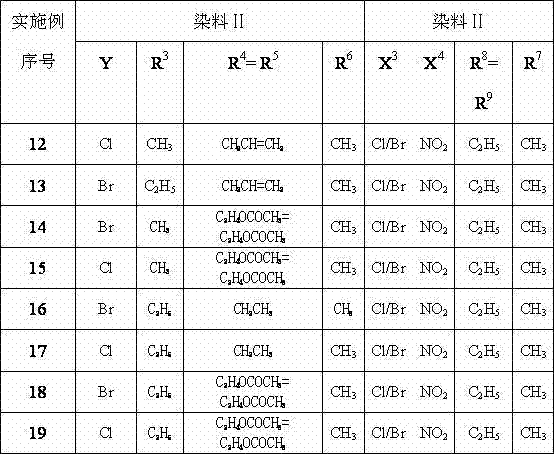

Embodiment 3~10

[0069] (1) 8.5 grams of dyestuff A with general formula (Ia) and 40.1 grams of dyestuff with general formula (II) (wherein various substituents are defined in Table 1), with 300 milliliters of water and 51.4 grams of lignosulfonic acid Sodium is ground together, according to the preparation method of embodiment 1, makes dyestuff mixture 3~10.

[0070] (2) According to the dyeing method of Example 1, when 0.4 gram of this dye mixture is used for dyeing polyester fiber fabrics, jet black and bright dyed samples 3 to 10 are obtained.

[0071] Dyes of formula (II) used in Table 1

[0072] Example Y R 3 R 6 R 4 R 5 3 Cl CH 3 CH 3 C 2 h 4 OCOCH 3 C 2 h 4 OCOCH 3 4 Br CH 3 CH 3 C 2 h 4 OCOCH 3 C 2 h 4 OCOCH 3 5 Cl C 2 h 5 CH 3 CH 2 CH 3 CH 2 CH 3 6 Br C 2 h 5 CH 3 CH 2 CH 3 CH 2 CH 3 7 Br C 2 h 5 CH 3 C 2 h 4 OCOCH 3 C 2 h 4 OCOCH 3 8 Cl C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com