Microcapsule of organic phase change energy storage material and preparation method thereof

A technology of energy storage materials and organic materials, which is applied in the field of microcapsules of organic phase change energy storage materials and its preparation, and can solve problems such as microcapsule damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0124] 4. Combining complex coagulation method with in-situ polymerization method, complex coacervation method and sol-gel method to prepare microcapsules of organic phase change energy storage materials with double-layer composite functional shells, including:

[0125] First, the method of complex coacervation is adopted, and the electrostatic interaction between two or more water-soluble polymer molecules with opposite charges is used, and the formed condensate undergoes phase separation in the water phase and deposits at the interface. After joint curing, the first polymer shell layer is formed, and the organic phase change energy storage material microcapsules of the first polymer shell layer are prepared. At the same time, organic phase change energy storage materials can be pre-dispersed into certain functional particles to prepare microcapsules with functional particles such as infrared reflection and absorption, ultraviolet reflection and absorption, thermal radiation r...

Embodiment 1

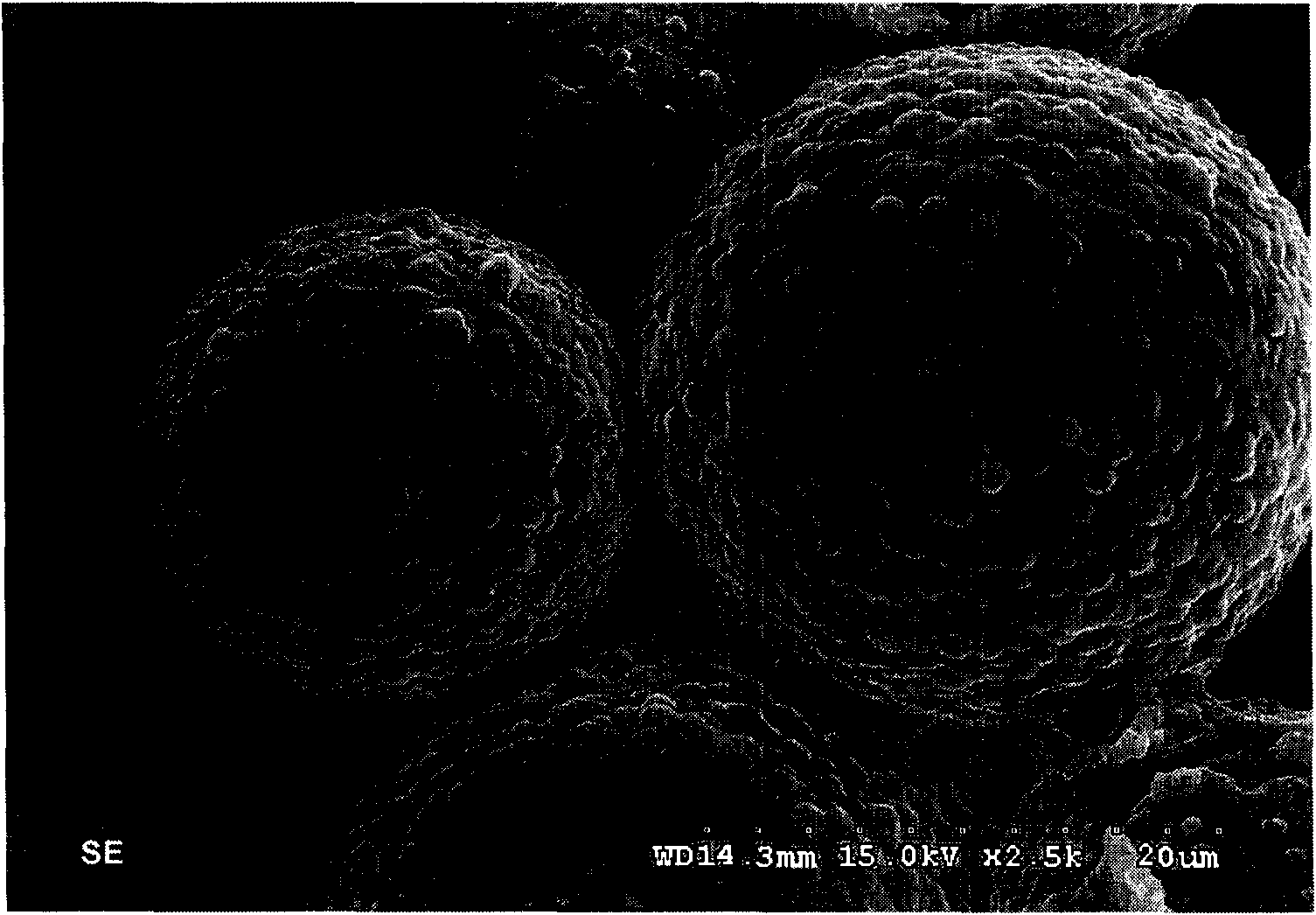

[0165] Example 1. Preparation of phase-change energy storage material microcapsules inlaid with hollow spheres by organic / organic composite shell encapsulating 30# phase-change wax by in-situ polymerization

[0166] Preparation of urea-formaldehyde prepolymer aqueous solution: Add 240g of urea and 488.5g of 37% formaldehyde aqueous solution into a three-necked flask equipped with a reflux condenser, mechanically stir to dissolve, add triethanolamine to adjust the pH of the system to 8, heat to 70°C, Insulate and react for 1 hour to obtain a viscous liquid, then add 1000 g of water to dilute to obtain a stable aqueous solution of urea-formaldehyde prepolymer.

[0167] Preparation of the sodium salt hydrolyzate solution of styrene-maleic anhydride copolymer: add a certain amount of toluene to a three-necked flask equipped with a condenser, a thermometer and an agitator, pass nitrogen to remove oxygen, and add 10% mole of toluene mass Styrene and maleic anhydride with a ratio of ...

Embodiment 2

[0171] Example 2. Preparation of microcapsules of paraffin wax phase-change energy storage materials with high-efficiency tissue slices with a melting point of 50-52°C in an organic / organic composite shell embedded with hollow spheres prepared by in-situ polymerization

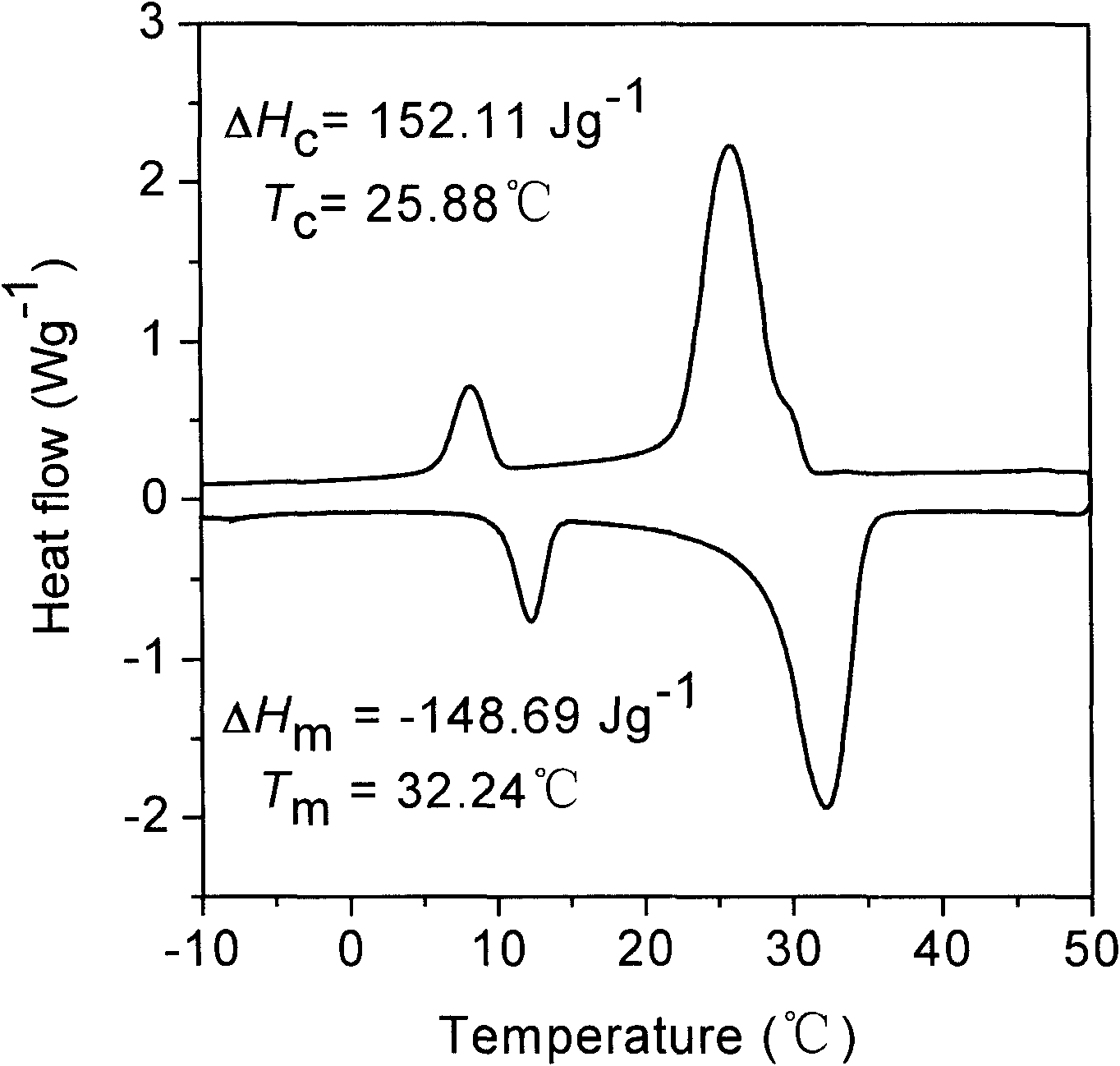

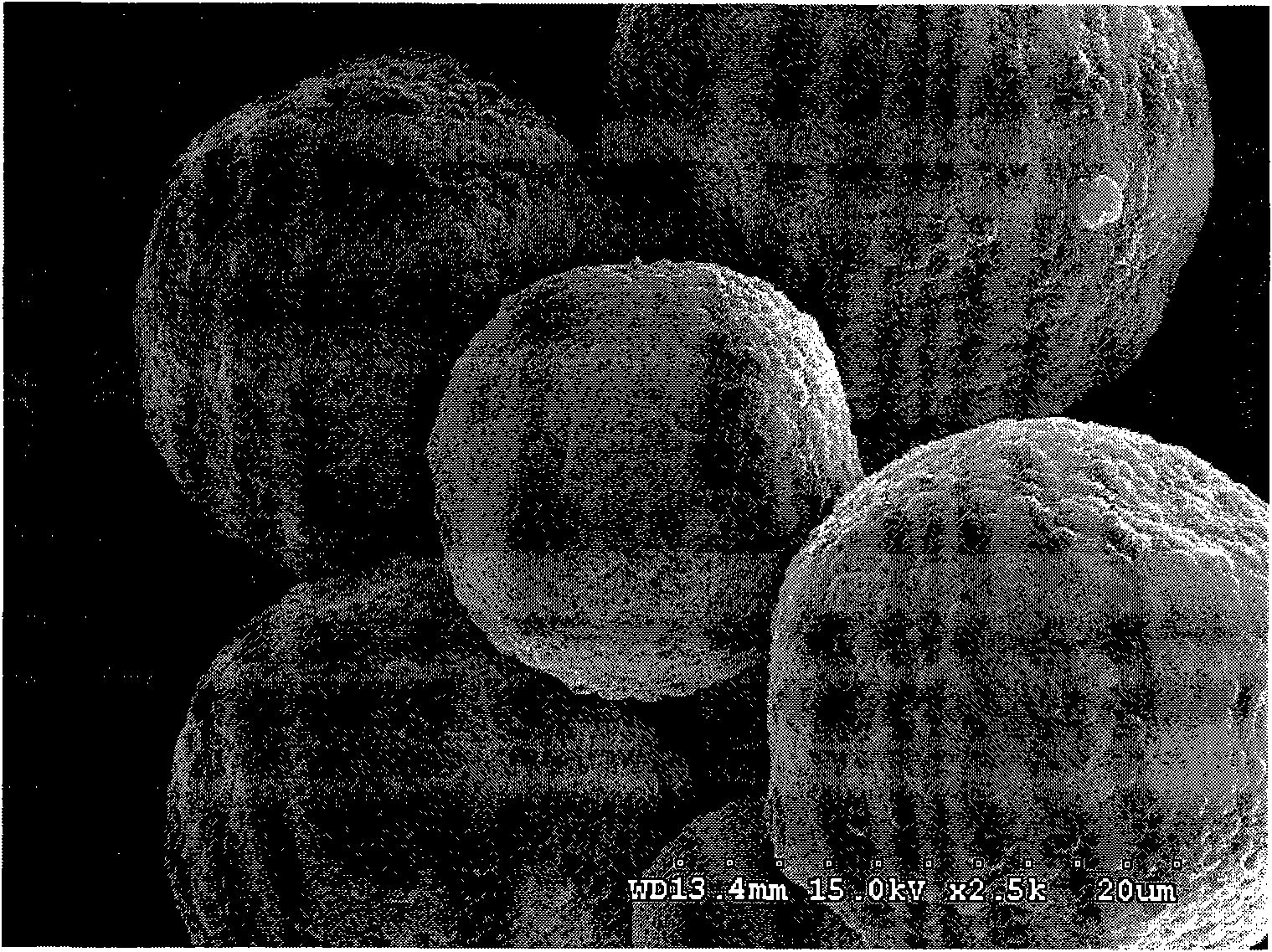

[0172] Get the sodium salt hydrolyzate solution of 10g 10% styrene-maleic anhydride copolymer among the embodiment 1, join in 100g water, adjust its pH value 5~6 with 1M hydrochloric acid, add 50g fusing point 50~52 ℃ high-efficiency Paraffin the tissue sections, keep the system at 75°C, use a high-speed shear emulsifier to emulsify at 10,000rpm for 10min, transfer the obtained emulsion to a three-necked flask in a water bath at 75°C, and stir mechanically.

[0173] Take 100 g of the urea-formaldehyde prepolymer aqueous solution in Example 1, add 2.5 g of sodium chloride to dissolve it, adjust the pH value of the solution to 5-6 with 1M hydrochloric acid, slowly drop it into a three-necked bottle of paraffin wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com