Anion-exchange agent prepared by using fermented straws, preparation method thereof and use thereof

An anion exchanger and ion exchanger technology, applied in the field of environment and chemistry, can solve problems such as low efficiency, high cost, and secondary pollution, and achieve the effects of high production efficiency, low cost, and less secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

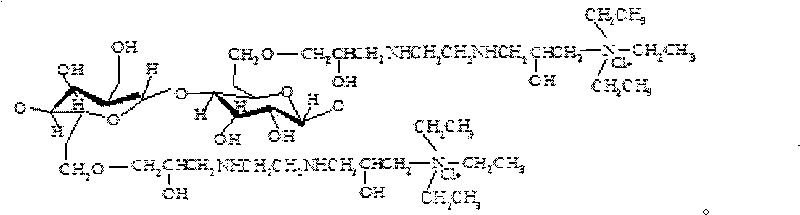

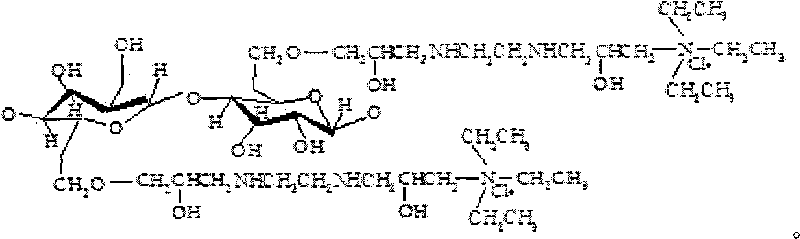

Method used

Image

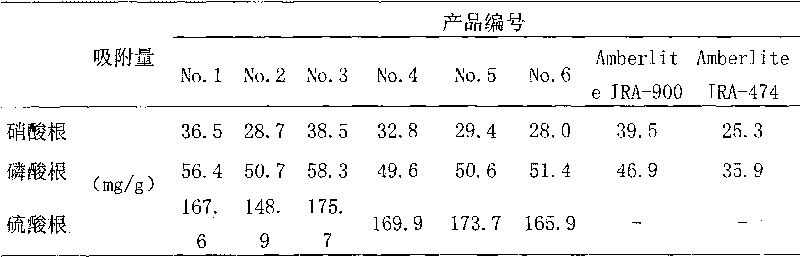

Examples

Embodiment 1

[0023] The fermented stalk is stirred and reacted with epichlorohydrin, and ethylenediamine is added, and then dimethylamine solution is added, and the batching ratio between them is fermented stalk: epichlorohydrin: ethylenediamine: triethylamine solution=10g: 10mL: 0.5mL: 10mL, the fermented straw anion exchanger was prepared. The specific preparation method is as follows:

[0024] (1) Take 10 g of fermented straw with a particle size of 200-500 μm in a 250 mL three-necked flask, add 10 mL of epichlorohydrin and stir at 85° C. for 60 minutes.

[0025] (2) Take 0.5 mL of ethylenediamine and add it to the above-mentioned 250 mL three-neck flask and continue to stir and react for 60 min, and the temperature is controlled at 85°C.

[0026] (3) Add 10 mL of dimethylamine solution with a mass percent concentration of 33%, the reaction temperature is 85° C., and the stirring time is 3 hours to obtain a solid product.

[0027] (4) The products were washed with the same volume of N...

Embodiment 2

[0029] Concrete preparation method and embodiment 1 difference are:

[0030] The amount of epichlorohydrin added in the step (1) was 1 mL, and the reaction was stirred at 20° C. for 150 minutes.

[0031] The amount of ethylenediamine added in step (2) was 5 mL, and the reaction was stirred at 20° C. for 150 minutes. .

[0032] The reactant added in step (3) is 20 mL of triethylamine with a mass percentage of 99%, the reaction temperature is 20° C., and the reaction time is 6 hours.

[0033] The obtained anion exchanger has a tan powder appearance, a Zeta potential of 10 mv, a nitrogen content of about 2.0%, and a pH value of 4.0. The product number is represented by No.2.

Embodiment 3

[0035] The difference between the preparation method and Example 1 is:

[0036] The amount of epichlorohydrin added in step (1) was 20 mL, and the reaction was stirred at 120° C. for 20 minutes.

[0037] The amide added in the step (2) was diethylenetriamine and was 10 mL, and the reaction was stirred at 120° C. for 30 minutes.

[0038] The mass percent concentration of dimethylamine added in step (3) is 69%, which is 20 mL, the reaction temperature is 120° C., and the reaction time is 0.5 hour.

[0039] The obtained anion exchanger has a brown powder appearance, a Zeta potential of 25.0 mv, a nitrogen content of about 3.3%, and a pH value of 5.2. The product number is represented by No.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com