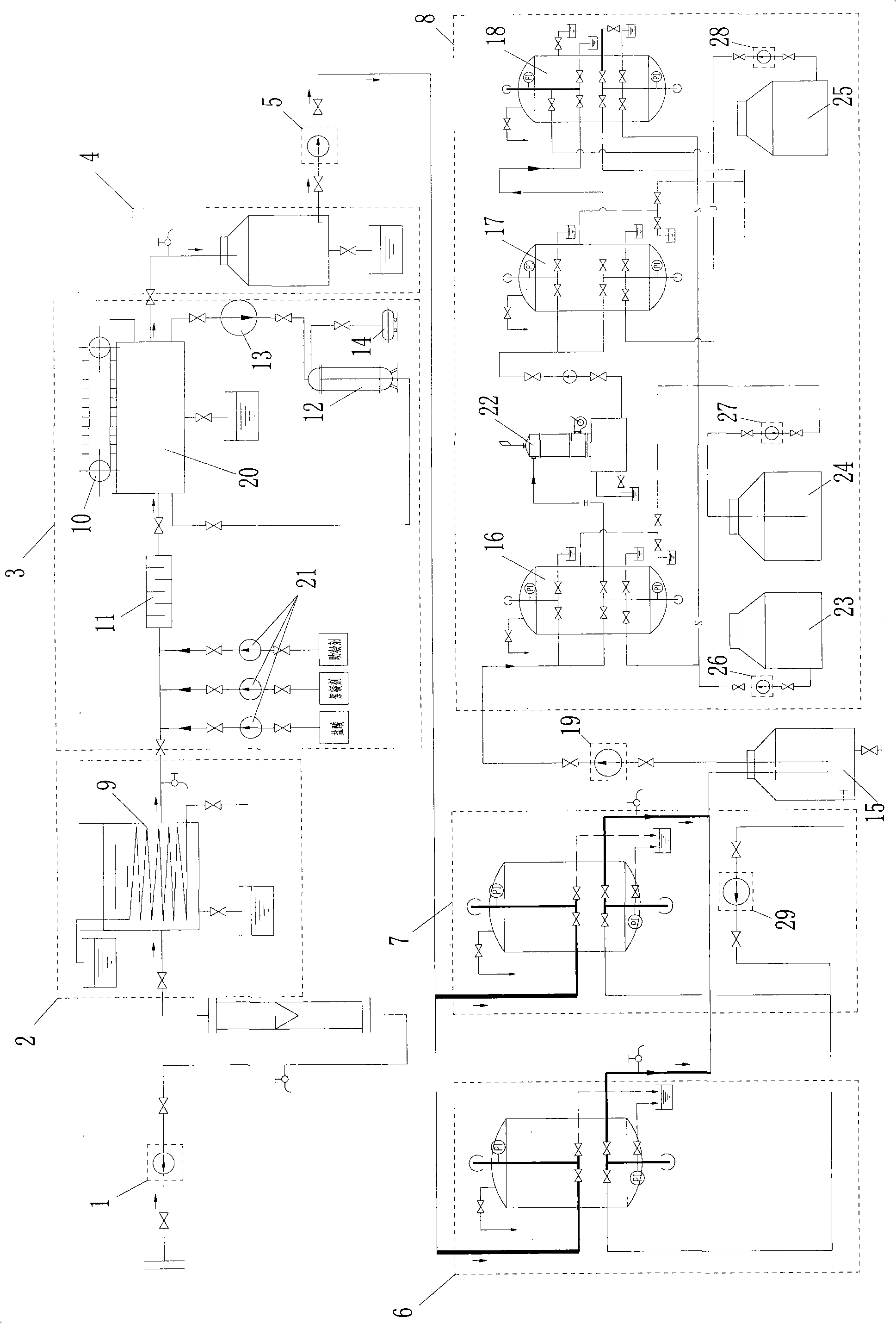

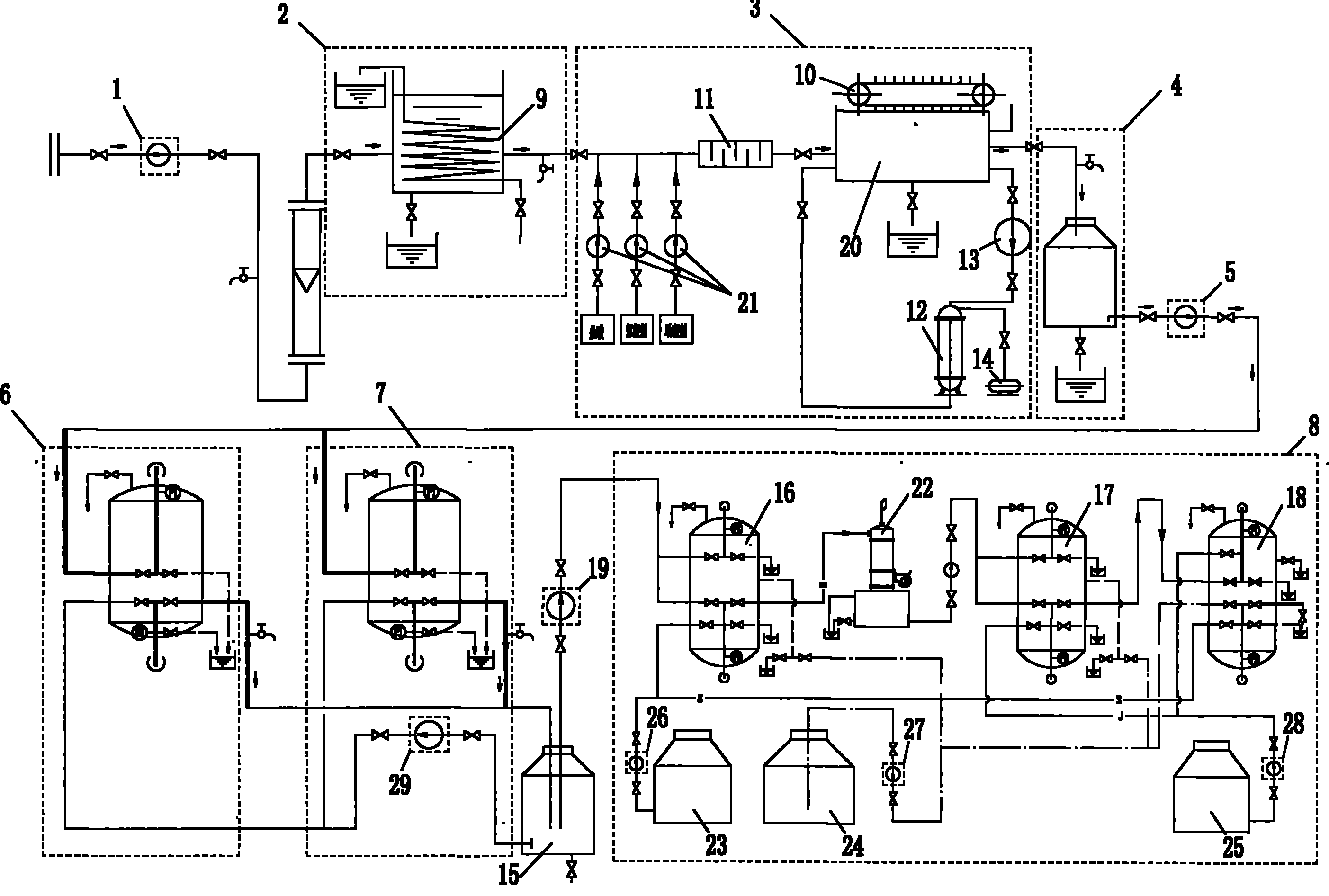

Water treatment method and device using aluminum oxide secondary condensation water as make-up water of power plant

A technology of condensed water and alumina, applied in water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as oil pollution, organic pollution, process impact, etc. The effect of avoiding pollution, reasonable and economical treatment costs, and resistance to load shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The concrete of this embodiment comprises the following steps:

[0045] 1) Cool down and degrade pollutants: After the secondary condensed water from the alumina plant is heated to 35°C through a surface heat exchanger, it is passed into the aeration tank for aeration. The air-water ratio of the aeration is 7:1 ;

[0046] 2) Flocculation and air flotation: the aerated water enters the air flotation device through the pipeline and enters the air flotation device for air flotation treatment. First, add hydrochloric acid to the inlet pipe of the air flotation device to adjust the pH value of the water to 7.0, then add PAC coagulant, add The dosage is about 10mg / L, and then PAM coagulant is added, and the dosage is about 1mg / L; the air flotation device adopts advection pressure dissolved air flotation, and the effective residence time is 1.5h during air flotation treatment. The reflux ratio of dissolved air water is 20%; the dosing amount of hydrochloric acid is adjusted b...

Embodiment 2

[0050] The concrete of this embodiment comprises the following steps:

[0051] 1) Cool down and degrade pollutants: After the secondary condensed water from the alumina plant is heated to 35°C through a surface heat exchanger, it is passed into the aeration tank for aeration. The air-water ratio of the aeration is 7:1 ;

[0052] 2) Flocculation and air flotation: the aerated water enters the air flotation device through the pipeline and enters the air flotation device for air flotation treatment. First, add hydrochloric acid to the inlet pipe of the air flotation device to adjust the pH value of the water to 7.3, then add PAC coagulant, add The dosage is about 20mg / L, and then PAM coagulant is added, and the dosage is about 1.5mg / L; the air flotation device adopts advection pressure dissolved air flotation, and the effective residence time is 1.5h during air flotation treatment , the reflux ratio of dissolved air water is 25%; the dosing amount of hydrochloric acid is adjuste...

Embodiment 3

[0056] The concrete of this embodiment comprises the following steps:

[0057] 1) Cool down and degrade pollutants: After the secondary condensed water from the alumina plant is heated to 35°C through a surface heat exchanger, it is passed into the aeration tank for aeration. The air-water ratio of the aeration is 7:1 ;

[0058] 2) Flocculation and air flotation: the aerated water enters the air flotation device through the pipeline for air flotation treatment, firstly add hydrochloric acid to the inlet pipe of the air flotation device to adjust the pH value of the water to 7.5, then add oxalic acid, the dosage About 30mg / L, then add PAM coagulant, the dosing amount is about 2mg / L; the air flotation device adopts advection pressure dissolved air flotation, during the air flotation treatment, the effective residence time is 1.5h, and the dissolved air The water reflux ratio is 30%; the dosing amount of hydrochloric acid is adjusted by the frequency conversion of the pH value f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com