System and method for manufacturing demineralized water

A production system, salt water technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problem that TOC content is not guaranteed, TOC removal is not considered, and it cannot meet the requirements of generator sets and other problems to achieve the effect of reducing the pollution index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

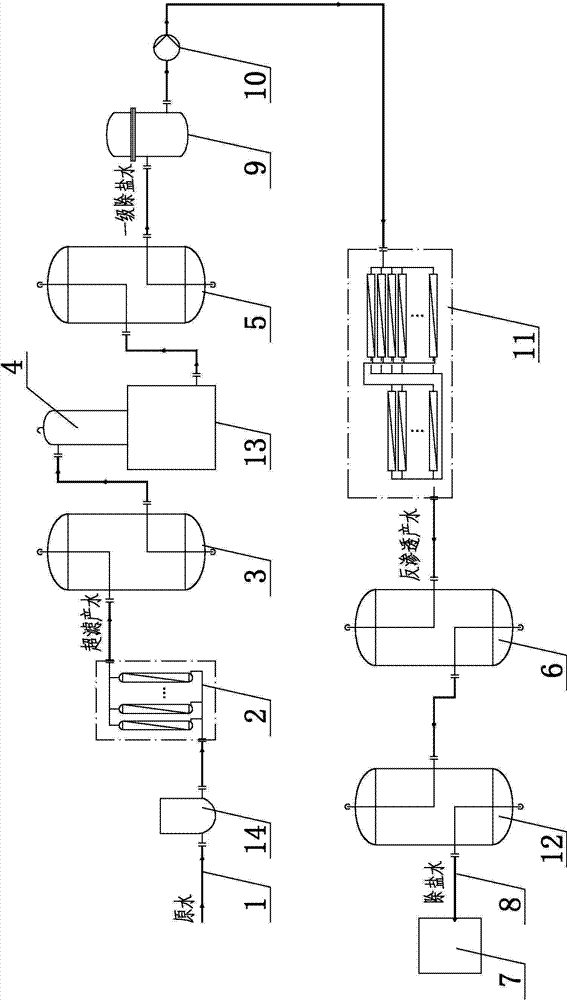

[0027] Embodiment 1 of the present invention: such as figure 1 As shown, a desalinated water production system includes an industrial water inlet 1, a pretreatment device 2, a cation exchanger 3, a decarbonizer 4, an anion exchanger 5, a first-stage mixed bed 6, and a decarbonization device, which are sequentially connected together by pipelines. The connecting pipeline between the brine tank 7 and the desalinated water outlet 8, the anion exchanger 5 and the first-stage mixed bed 6 is sequentially provided with a security filter 9, a high-pressure pump 10 and a reverse osmosis device 11; the first-stage mixed bed 6 and the desalinated water The connecting pipeline between the outlets 8 is provided with a polishing mixed bed 12.

[0028] The pretreatment device 2 adopts ultrafiltration equipment, and an ultrafiltration water tank and a filtration water pump are also provided between the ultrafiltration equipment and the cation exchanger 3. The pretreatment device 2 adopts a mult...

Embodiment 2

[0032] Embodiment 2 of the present invention: such as figure 1 As shown, a desalinated water production system includes an industrial water inlet 1, a pretreatment device 2, a cation exchanger 3, a decarbonizer 4, an anion exchanger 5, a first-stage mixed bed 6, and a decarbonization device, which are sequentially connected together by pipelines. The connecting pipeline between the brine tank 7 and the desalinated water outlet 8, the anion exchanger 5 and the first-stage mixed bed 6 is sequentially provided with a security filter 9, a high-pressure pump 10 and a reverse osmosis device 11; the first-stage mixed bed 6 and the desalinated water The connecting pipeline between the outlets 8 is provided with a polishing mixed bed 12.

[0033] The pretreatment device 2 adopts ultrafiltration equipment, and an ultrafiltration water tank and a filtration water pump are also provided between the ultrafiltration equipment and the cation exchanger 3. The pretreatment device 2 uses an activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com