Biomaterial modified with hydrophilic lubrication coating on surface and preparation method of biomaterial

A technology of lubricating coatings and biomaterials, applied in the direction of coatings, etc., can solve problems such as high requirements for solution rheological properties, inability to lubricate modification, complicated preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The invention provides a method for preparing a biomaterial whose surface is modified with a hydrophilic lubricating coating, comprising the following steps:

[0019] Mix vinyl active monomer, dopamine hydrochloride and tris buffer to form a precursor solution;

[0020] The biological base material to be modified is immersed in the precursor solution to carry out polymerization reaction, and the biological material with a hydrophilic lubricating coating on the surface is obtained.

[0021] The invention mixes vinyl active monomers, dopamine hydrochloride and tris buffer to form a precursor solution. In the present invention, the vinyl reactive monomer preferably includes acrylamide (AAm), N-isopropylacrylamide (NIPAAm), hydroxyethyl methacrylate (HEMA), ethylene glycol methacrylate (OEGMA ), polyoxyethylene methacrylate (PEGMA), acrylic acid (AA), sodium methacrylic acid (MAA), methacryloyloxyethyl dimethyl ammonium chloride (METAC), methacrylic acid N,N - Dimethylami...

Embodiment 1

[0033] Hydrophilic coating for PVC catheter surface modification:

[0034] (1) Weigh 100 mg of dopamine hydrochloride and 500 mg of methacryloyloxyethyl phosphorylcholine (MPC) and dissolve them in 100 mL of Tris buffer solution (10 mM, pH=8.5), stir rapidly until the solid is completely dissolved to obtain the precursor body solution;

[0035] (2) Immerse the medical PVC urinary catheter into the above precursor solution, take it out after reacting at room temperature for 10 hours, wash it with ethanol and secondary deionized water, and dry it in an oven to obtain the surface-modified polydopamine hydrochloride-polymethacryl Oxyethylphosphorylcholine (PDA-PMPC) coated PVC catheter.

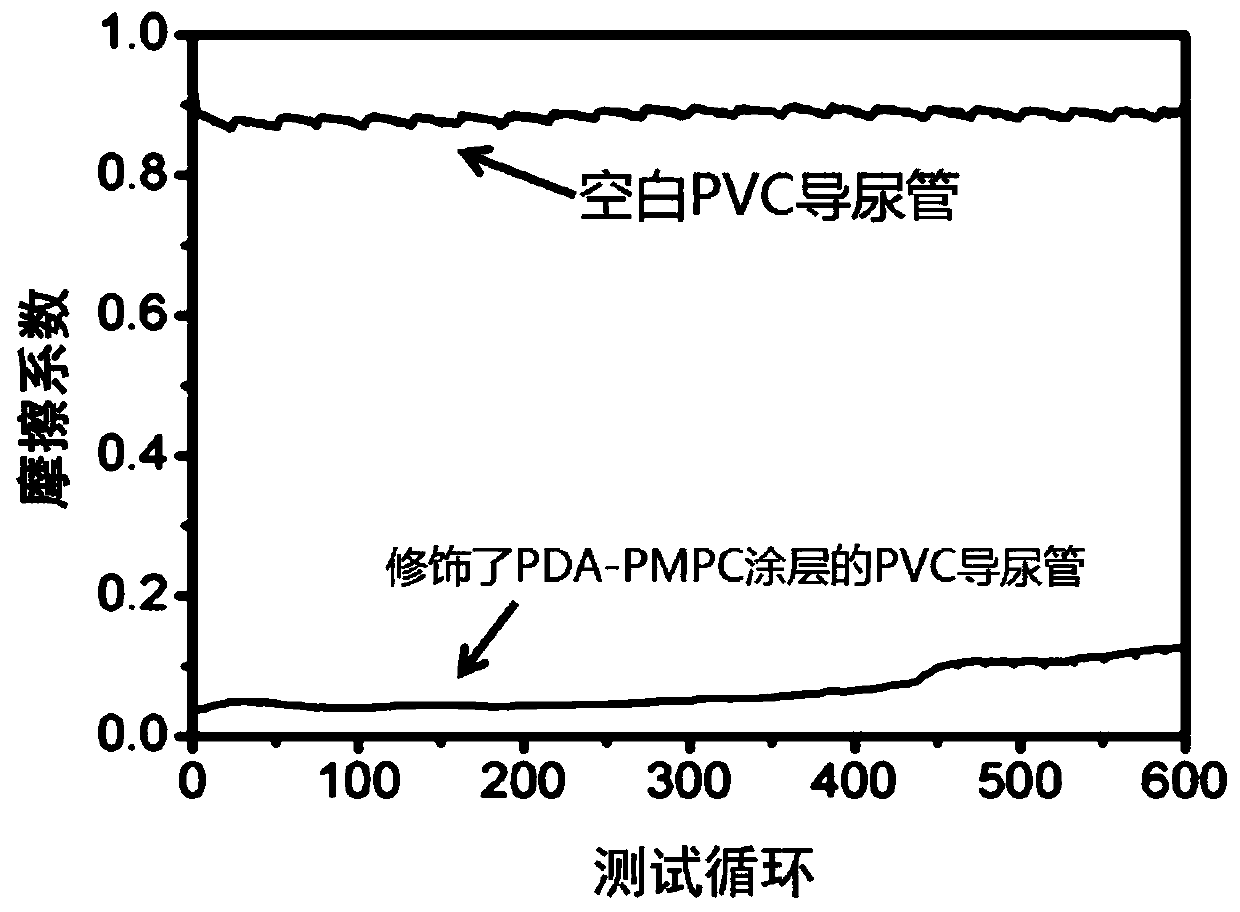

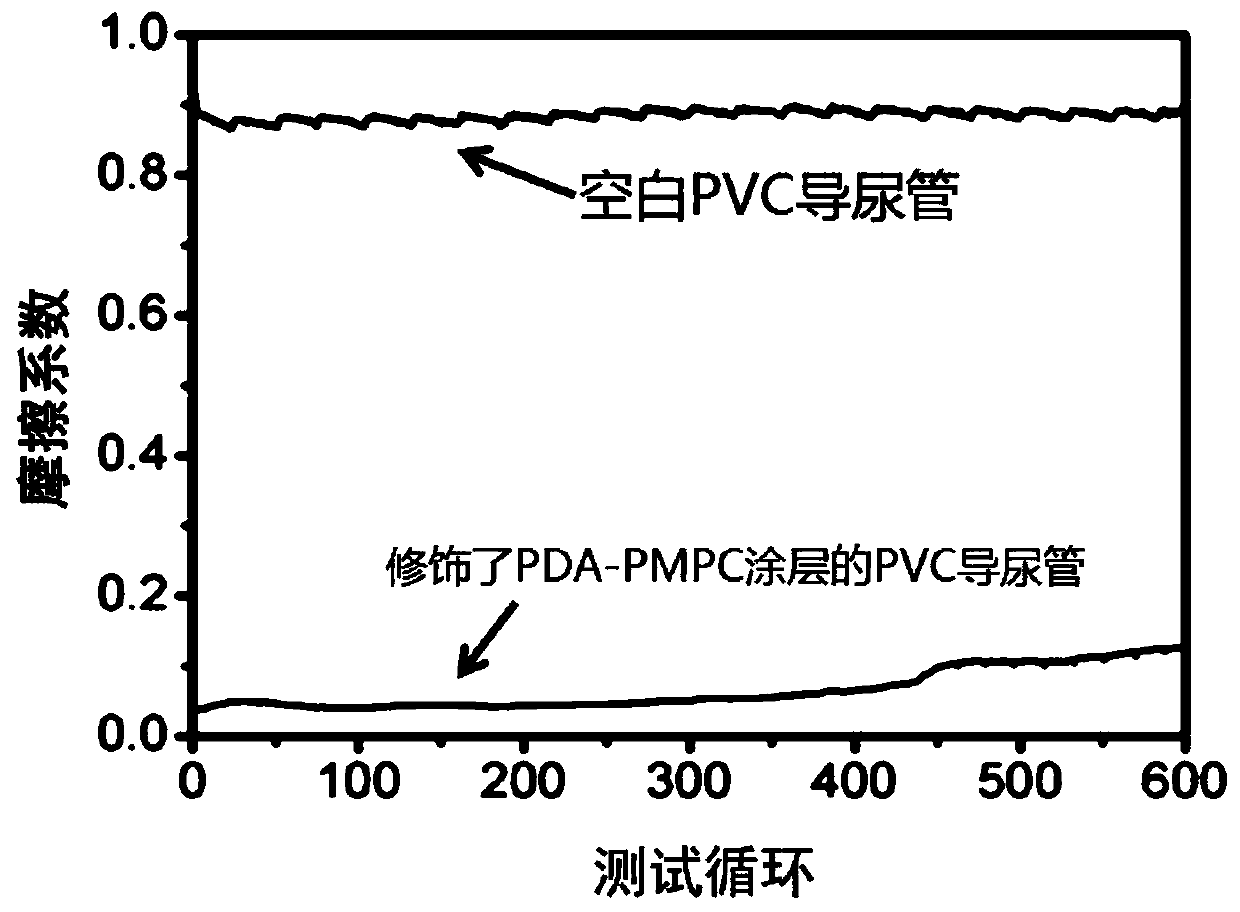

[0036] The photo of the PVC urinary catheter of the PDA-PMPC coating that the present embodiment obtains is modified is as figure 1 shown.

[0037] Characterization of coating physical and chemical properties:

[0038] (1) Characterization of coating thickness: measured by ellipsometer and at...

Embodiment 2

[0043] Hydrophilic coating on the surface of PDMS sheet:

[0044] (1) Weigh 100mg of dopamine hydrochloride and 1000mg of 3-sulfopropyl methacrylate potassium salt (SPMA) and dissolve them in 100mL of Tris buffer solution (10mM, pH=8.5), stir rapidly until the solid is completely dissolved to obtain the precursor solution;

[0045] (2) Immerse the polydimethoxysiloxane (PDMS) sheet in the above precursor solution, take it out after 20 hours of reaction at room temperature, rinse with ethanol and secondary deionized water, and dry in an oven, that is, on the surface of the PDMS sheet The polydopamine hydrochloride-polymethacrylate 3-sulfonate propyl potassium salt (PDA-PSPMA) coating was successfully modified.

[0046] Characterization of coating physical and chemical properties:

[0047] (1) Characterization of coating thickness: measured by ellipsometer and atomic force microscope, the thickness of PDA-PSPMA coating is 35nm.

[0048] (2) Characterization of wettability: ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com