A kind of environment-friendly air filter non-woven fabric and its production process and application

An air filtration and production process technology, applied in filtration and separation, textiles and papermaking, non-woven fabrics, etc., can solve the problems of low charge stability of melt-blown polypropylene fibers, difficult to maintain high efficiency and low resistance performance, etc., to improve the electret Chemical effect, improve storage stability, good electret effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

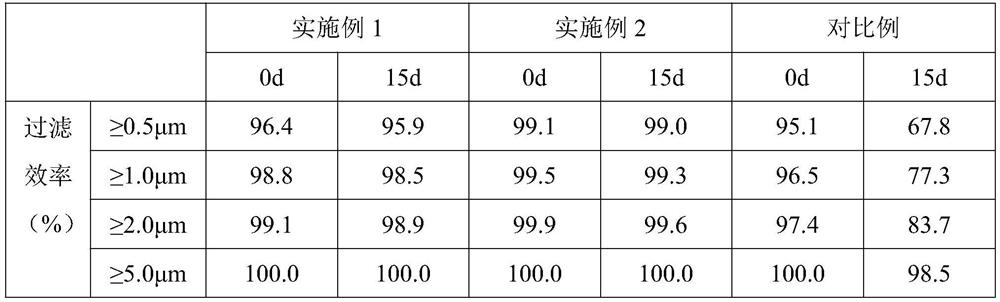

Examples

preparation example Construction

[0037] The electret master batch is composed of polypropylene, few-layer graphene nanosheets, antioxidant, compatibilizer, nucleating agent; the preparation method of the electret master batch comprises the following steps:

[0038] a1, take 5g of magnesia microcrystalline powder and place it in an alumina ceramic boat, move the ceramic boat equipped with magnesia microcrystalline powder into the middle of the tube furnace, close the tube furnace, replace the air in the tube with argon, Adjust the flow rate of argon gas at 100-120ml / min, gradually heat the tube furnace to 920-1000°C, the heating rate is 8-10°C / min, keep warm for 10-30min after the temperature reaches the target temperature, and switch the atmosphere to methane and The mixed gas of hydrogen, the flow rate of the mixed gas is constant at 60-72ml / min, start to deposit few layers of graphene on the surface of the magnesium oxide microcrystal, the deposition time is 90-100min, after the deposition is completed, the ...

Embodiment 1

[0057] A kind of production technology of environment-friendly air filter non-woven fabric, comprises the following steps:

[0058] S1. Mix polypropylene, electret masterbatch and polymer electret uniformly to prepare a mixture; wherein, the weight ratio of the polypropylene, the electret masterbatch and the polymer electret is 100 :6:0.5;

[0059] S2. Feed the mixture into a screw extruder, and melt and extrude it to form a melt. The temperatures of the five heating zones of the screw extruder are respectively set to 160°C, 180°C, 200°C, 220°C, 225°C;

[0060] S3, the melt is kept in the pipeline at a constant temperature, and after being metered by a metering pump, it is sprayed out through a spinneret to form fibers, and the fibers are drawn by hot air at a constant temperature and pressure to form a melt-blown cloth on the mesh curtain;

[0061] S4. The melt-blown cloth prepared in S3 is subjected to constant temperature infrared radiation heat treatment, 50,000-60,000 v...

Embodiment 2

[0071] A kind of production technology of environment-friendly air filter non-woven fabric, comprises the following steps:

[0072] S1. Mix polypropylene, electret masterbatch and polymer electret uniformly to prepare a mixture; wherein, the weight ratio of the polypropylene, the electret masterbatch and the polymer electret is 100 :6:0.5;

[0073] S2. Feed the mixture into a screw extruder, and melt and extrude it to form a melt. The temperatures of the five heating zones of the screw extruder are respectively set to 160°C, 180°C, 200°C, 220°C, 225°C;

[0074] S3. The melt is kept in the pipeline at a constant temperature, and after being metered by a metering pump, it is sprayed out through a spinneret to form fibers. The fibers are drawn by hot air at a constant temperature and pressure to form a melt-blown cloth on a mesh curtain. Meltblown cloth is subjected to surface modification treatment, specifically:

[0075] S4. Under a protective atmosphere, add 0.65g of dodecy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com