A kind of highly compatible polypropylene electret masterbatch, its preparation method and melt-blown cloth

A technology of polypropylene melt-blown and polypropylene, applied in the direction of single-component polyolefin artificial filament, non-woven fabric, rayon manufacturing, etc., to achieve stable charge storage, increase tensile strength, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

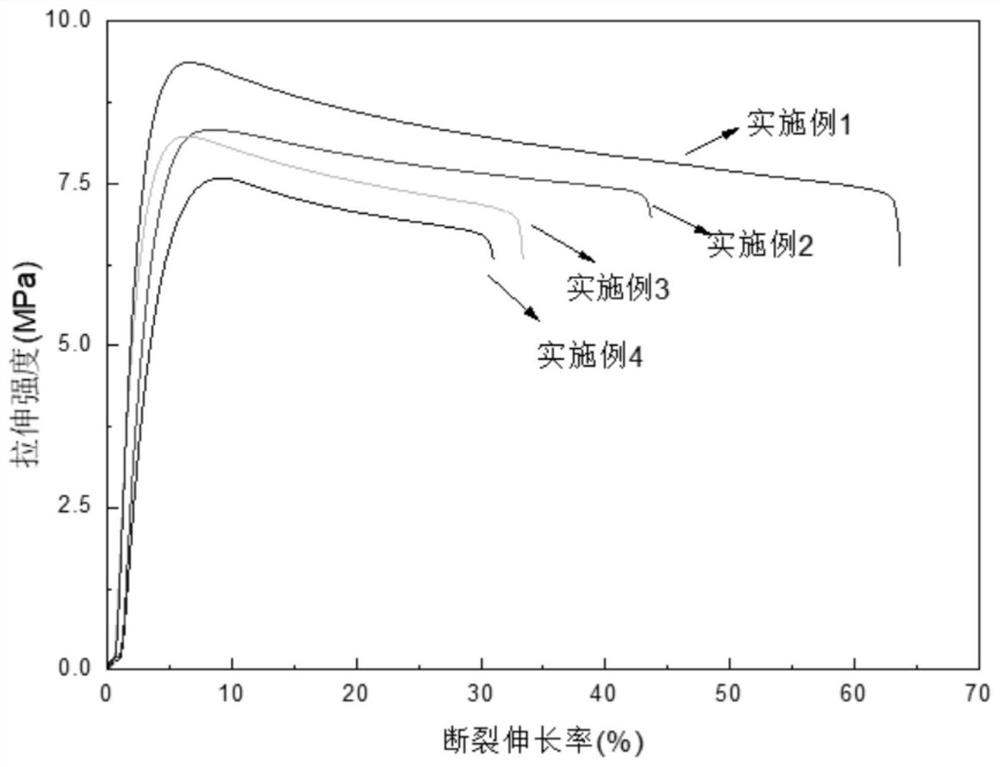

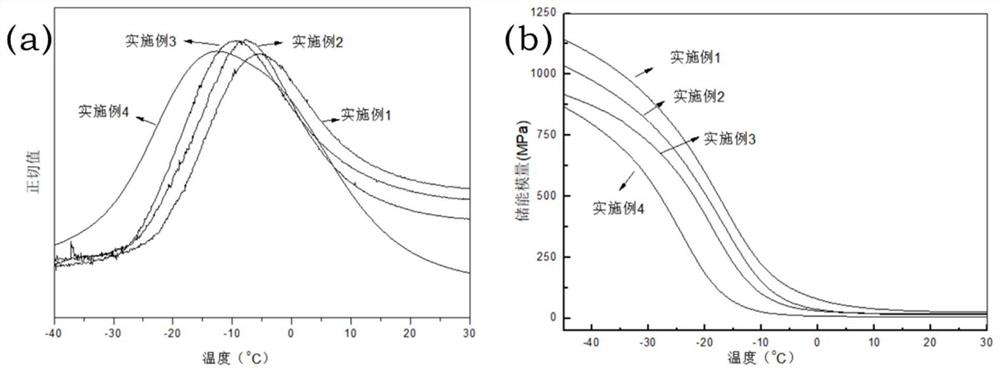

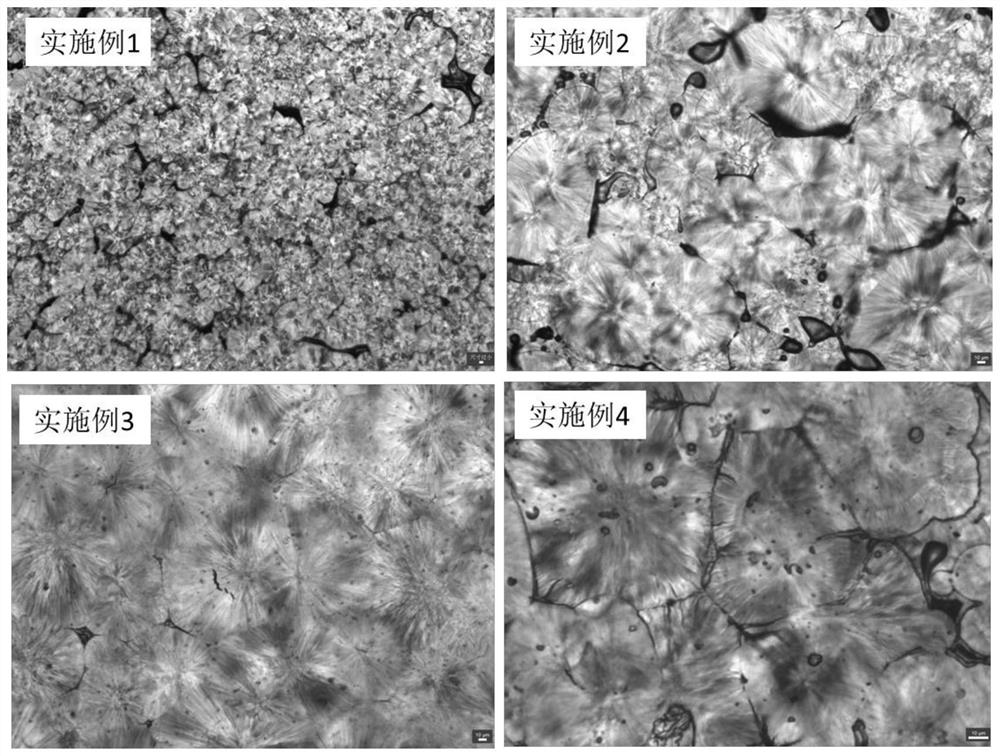

Embodiment 1

[0032] (1) Blend tourmaline (Lingshou County Guanghui Mine Products Processing Company, 2500 mesh) and magnesium stearate (He Nanyijia Biotechnology Co., Ltd., 400 mesh) in a high-speed mixer to mix tourmaline and magnesium stearate Homogeneous to obtain mixture A; take polypropylene (Sinopec, melting index 25g / 10min), polyvinylidene fluoride (Arkema, KYNAR 340) and ethylene-chlorotrifluoroethylene copolymer (Sinochem Lantian Group Co., Ltd. ) in a high-speed mixer to obtain mixture B, then add mixture A, and continue to mix evenly, wherein the mass ratio of polypropylene, polyvinylidene fluoride, ethylene-chlorotrifluoroethylene copolymer, tourmaline, and magnesium stearate is 1:0.3:0.1:0.2:0.05.

[0033] The mixture was melted and extruded through a twin-screw extruder, cooled in a water tank and pelletized by a pelletizer, wherein the blending temperature in the twin-screw extruder and extrusion melt-blown equipment was 242 ° C, the screw speed was 50 rpm, and the drying A...

Embodiment 2

[0037] According to the preparation process of Example 1, no magnesium stearate was added in step (1), other raw material ratios and preparation process were unchanged, and meltblown raw materials and electret meltblown cloth were obtained.

Embodiment 3

[0039] According to the preparation process of Example 1, the ethylene-chlorotrifluoroethylene copolymer was not added in step (1), and the proportions of other raw materials and preparation conditions were unchanged to obtain meltblown raw materials and electret meltblown cloth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com