Plasma hot air electret equipment

A plasma and electret technology, used in textiles and papermaking, fiber processing, physical processing, etc., can solve the problems of unavoidable corona charging, small mechanical force, limited ultrasonic power, etc., to improve electret efficiency and improve application. Uniform and stable performance and charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

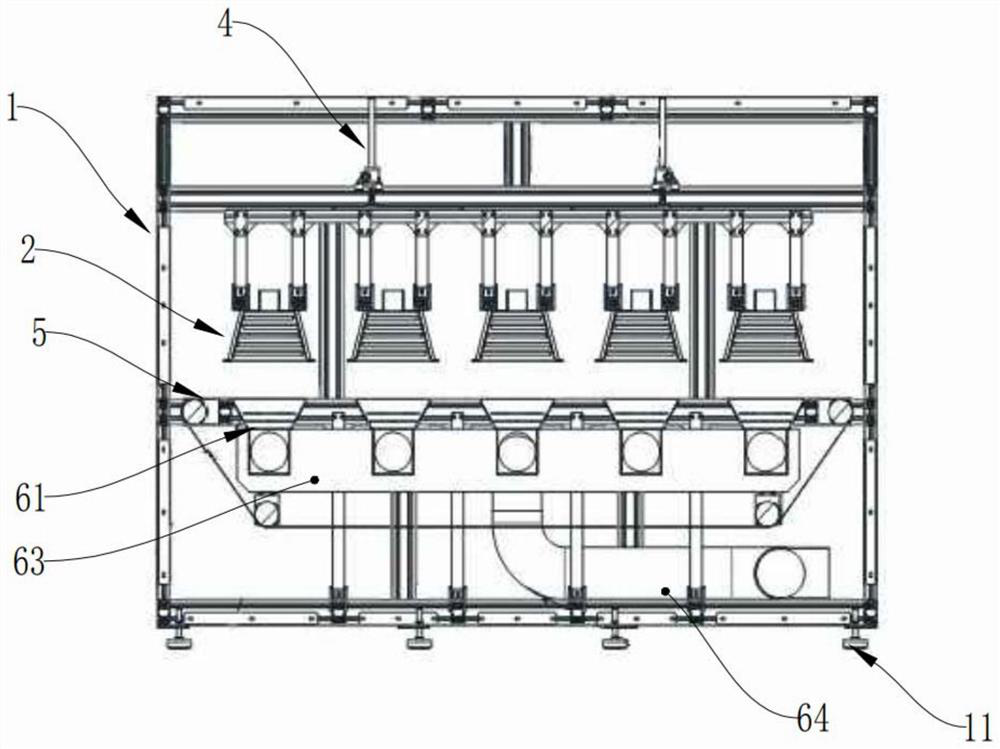

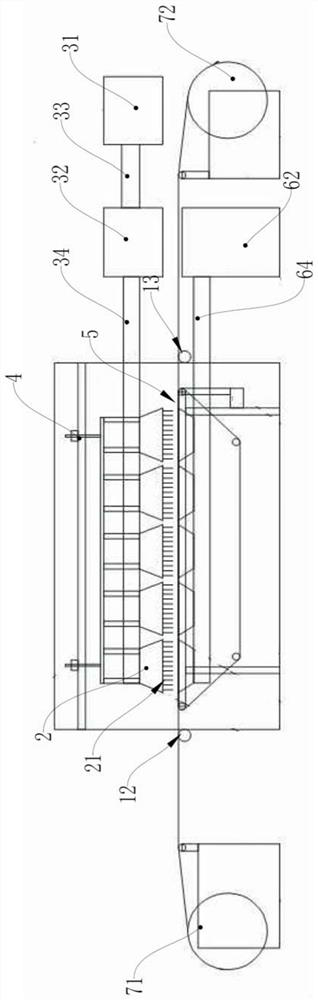

[0028] A kind of plasma hot air electret equipment of this embodiment, as attached Figure 1-2 Shown, comprise frame 1, hot air device and be located at the lifting platform 4 on frame 1, transfer device 5, a plurality of electret nozzle groups 2 and exhaust device, a plurality of electret nozzle groups 2 are located at the lifting platform 4 The movable end, the fixed end of the lifting platform 4 is connected to the frame 1, and the transmission device 5 is arranged directly under the plurality of electret nozzle groups 2, and the bottom of each electret nozzle group 2 is provided with a plurality of electret micro-holes The needles 21, each electret microhole needle 21 communicates with the output end of the hot air device. The exhaust device comprises a plurality of suction hoods 61 and a negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com