Low-odor, high-toughness and high-electret polypropylene melt-blown material and preparation method thereof

A polypropylene melt-blown, high-toughness technology, which is applied in filament molding, fiber processing, textiles and papermaking, etc., can solve the problem of large variation range of melt flow rate of melt-blown materials, incomplete degradation of peroxides, and molecular weight distribution. Wide and other problems, to achieve good toughening effect, complete peroxide degradation reaction, and narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

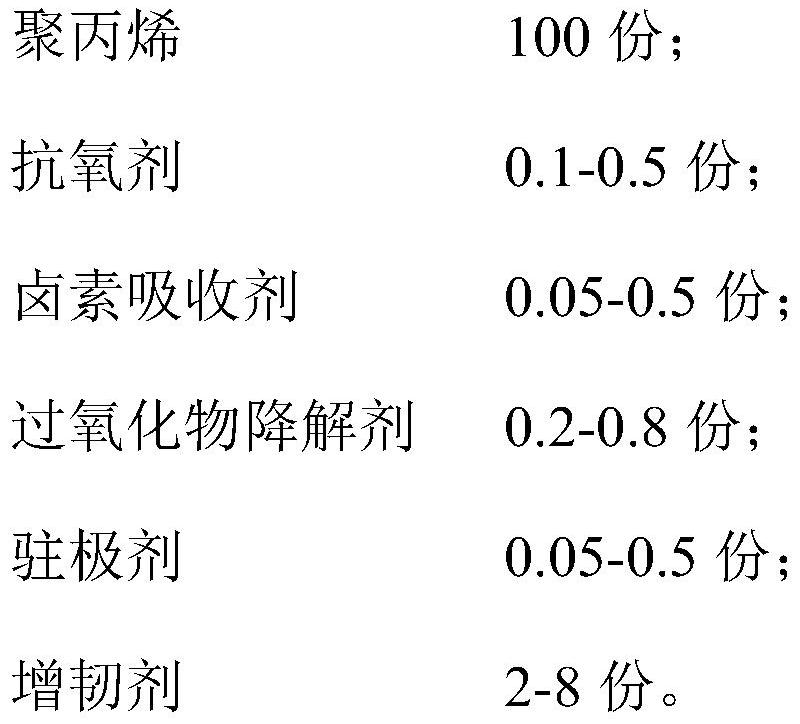

[0036] The polypropylene is Satellite Petrochemical PPH225 with a melt index of 25g / 10min. The antioxidant is composed of antioxidant 1010 and antioxidant 168 in a mass ratio of 2:1. The halogen absorbent is calcium stearate. The peroxide degrader is BIPB. The electret is tourmaline powder with an average particle size of 0.3um. The toughening agent is ExxonMobil POE8880, the viscosity at 190°C is 1200cP.

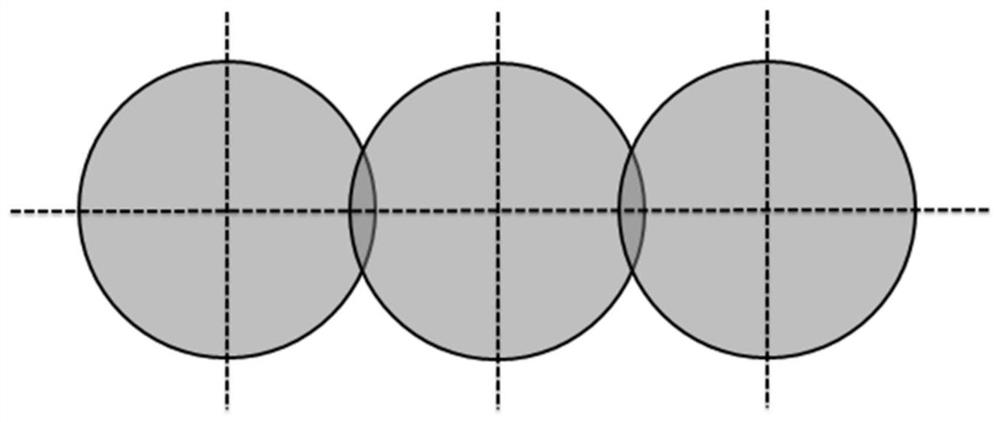

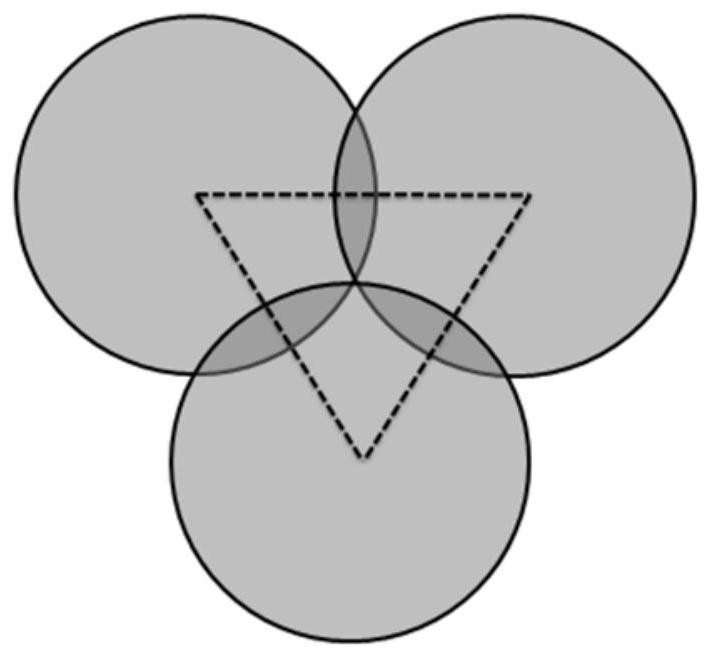

[0037] The preparation method of polypropylene melt-blown material. Choose a three-screw extruder with a length-to-diameter ratio of 45:1, and the arrangement of the three-screw meshing areas is in the shape of a "one", such as figure 1 As shown, there are feeding section, conveying section, melting section, exhaust section and homogenizing section. There are three precision weight loss scales at the feeding section, which are the first weight loss scale, the second weight loss scale and the third weight loss scale. There are two vacuum systems in the gas section, and ...

Embodiment 2

[0039] The polypropylene is Satellite Petrochemical PPH225 with a melt index of 25g / 10min. The antioxidant is composed of antioxidant 1010 and antioxidant 168 in a mass ratio of 2:1. The halogen absorbent is zinc stearate. The peroxide degrader is BIPB. The electret is a mixture of tourmaline powder and EBS (N,N'-ethylene bisstearamide) at a mass ratio of 2:1, and the average particle size of tourmaline powder is 0.3um. The toughening agent is ExxonMobil POE8880, the viscosity at 190°C is 1200cP.

[0040] The preparation method is the same as that of the polypropylene melt-blown material in Example 1.

Embodiment 3

[0042]The polypropylene is Satellite Petrochemical PPH225 with a melt index of 25g / 10min. The antioxidant is composed of antioxidant 1010 and antioxidant 168 in a mass ratio of 2:1. The halogen absorbent is calcium stearate. The peroxide degrader is DTBP. The electret is a mixture of tourmaline powder and EBS (N,N'-ethylene bisstearamide) at a mass ratio of 2:1, and the average particle size of tourmaline powder is 0.3um. The toughening agent is ExxonMobil POE8880, the viscosity at 190°C is 1200cP.

[0043] The preparation method is the same as that of the polypropylene melt-blown material in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com