Special organic electret master batch for melt-blown non-woven fabric applied to mask and preparation method thereof, and melt-blown non-woven fabric prepared from special organic electret master batch

A technology of melt-blown non-woven fabrics and electret, which is applied in non-woven fabrics, rayon manufacturing, textiles and papermaking, etc., and can solve problems such as small molecular weight, precipitation migration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

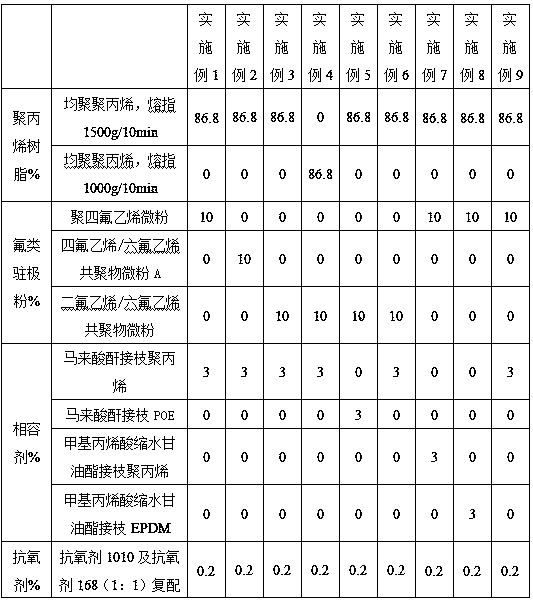

Embodiment 1~9

[0048] According to the formula in Table 1, the materials of Examples 1 to 5 and 7 to 8 were mixed in a high-speed mixer, and melted and extruded through a twin-screw extruder with a length-to-diameter ratio of 40:1. The temperature of the melting section was 150-210. ℃ to obtain the special organic electret masterbatch for the meltblown non-woven fabric for masks.

[0049] Add the polytetrafluoroethylene micropowder in Example 9 to 500 mL of water containing surfactants, disperse to form an emulsion, and mix in a high-speed mixer according to the formula in Table 1, and pass through a twin-screw extruder with a length-to-diameter ratio of 40:1 Melt blending and extrusion, combined with vacuum treatment to remove water during extrusion, and the temperature in the melting section is 150-210°C to obtain special organic electret masterbatches for meltblown non-woven fabrics for masks.

[0050] According to the formula in Table 1, the materials of Example 6 were mixed in a high-speed m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com