A long-lasting melt-blown polypropylene composite electret material for mask melt-blown cloth and preparation method thereof

A technology of melt-blown polypropylene and electret, which is applied in the direction of non-woven fabrics, rayon manufacturing, and single-component polyolefin rayon. It can solve the problems of poor long-term performance, promote charge capture, and simplify processing and molding. , good electret effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

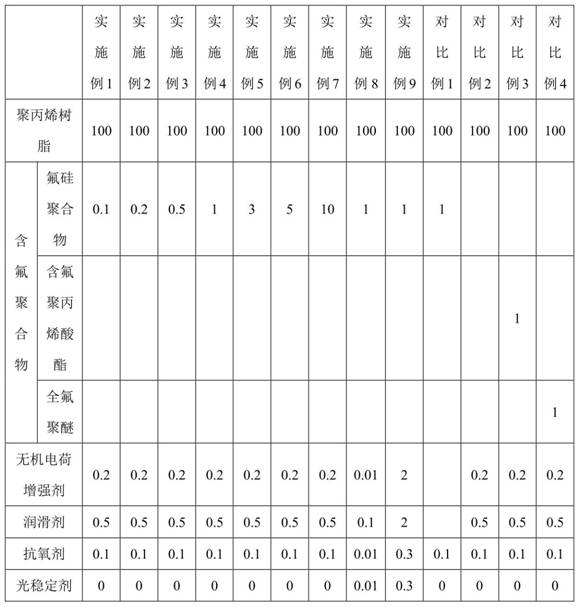

[0048] (1) The dosage of the components of the long-lasting melt-blown polypropylene composite electret material used for the mask melt-blown cloth in Examples 1-9 is shown in Table 1.

[0049] Among them, the melt flow rate of polypropylene resin (g / 10min, temperature 230°C, load 2.16kg): in Examples 1-7, it is specifically 800g / 10min; in Example 8, it is specifically 1500g / 10min; in Example 9 Specifically, it is 1800g / 10min. The test method of the melt flow rate of polypropylene resin: According to the GB / T3682-2000 standard B method, the heating temperature is set to 230°C, and the rated load is set to 2.16kg to normally detect the MFI melt index of the sample to be tested.

[0050] Fluorosilicone polymer: Fluorosilicone polymer was purchased from Zhejiang Jiahua. In Examples 1 to 9, the fluorosilicone polymer is a fluorine-containing polysiloxane with a silicon-oxygen bond as the main chain and a fluoroalkyl group as a side chain, the end group of the main chain is methyl, ...

Embodiment 8

[0059] The preparation method of the long-acting melt-blown polypropylene composite electret material for the mask melt-blown cloth of embodiment 8 and embodiment 9:

[0060] S21. Blend and extrude 30 parts of polypropylene resin from 100 parts of polypropylene resin with fluorosilicon polymer, inorganic charge enhancer, lubricant, antioxidant and light stabilizer to obtain charge enhancer masterbatch: (a) Weigh each component according to the weight ratio, add it to the high mixer and mix for 1-3 minutes at a speed of 1000-2000 rpm to obtain a premix; (b) The premix is melted and extruded by a twin-screw extruder The temperature of each zone of the screw is 190~230°C, and the charge enhancer masterbatch is obtained by vacuum granulation.

[0061] S22. The remaining polypropylene and the charge enhancer masterbatch of step S11 are blended and melt-blown to obtain a long-lasting melt-blown polypropylene composite electret material: the remaining polypropylene and the charge e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com