Preparation and application method of electret material for degradable resin

A technology for degrading resins and biodegradable plastics, applied in the manufacture of rayon, single-component polyester rayon, chemical characteristics of fibers, etc., can solve the problems of unstable product quality, increase testing costs, etc., and achieve high electret effect , Improve the filter efficiency, the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

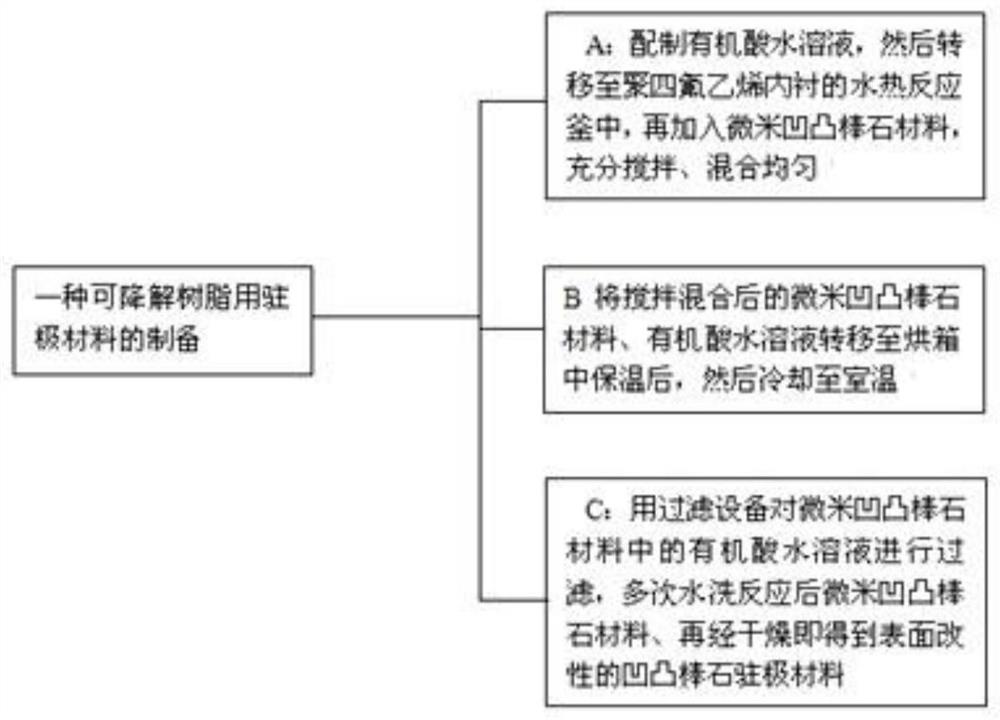

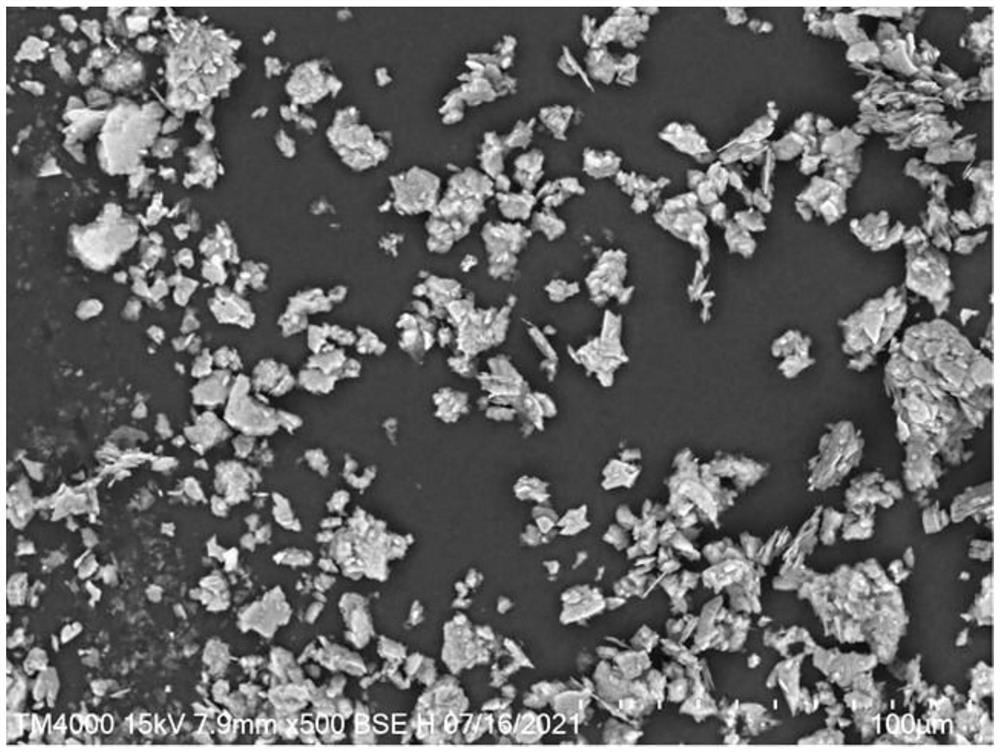

[0017] figure 1 As shown, a preparation of electret material for degradable resin, the preparation of electret material adopts micron attapulgite and organic acid aqueous solution as raw materials, organic acid includes one or more of oxalic acid, malic acid, citric acid, organic acid The concentration of the aqueous acid solution is 0.5mol / / L~10mol / L. The preparation process of the electret material is as follows. A: Prepare an aqueous solution of organic acid, then transfer it to a polytetrafluoroethylene-lined hydrothermal reactor, and then add micron attapulgite Stone materials, fully stirred, mixed evenly, wherein the hydrothermal temperature in the hydrothermal reaction kettle is 80 ℃ ~ 250 ℃, and the hydrothermal time is 0.5h ~ 4h; B: Micron attapulgite material and organic acid aqueous solution after stirring Transfer to an oven for heat preservation, and then cool to room temperature; C: Filter the organic acid aqueous solution in the micron attapulgite material with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com