Preparation and application method of electret material for biodegradable plastic

A technology of biodegradable plastics and electret, applied in the manufacture of rayon, single-component polyester rayon, fiber chemical characteristics, etc., can solve the problems of unstable product quality, increase the cost of enterprise testing, etc., and achieve high electret effect, promoting interfacial bonding, and reducing air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

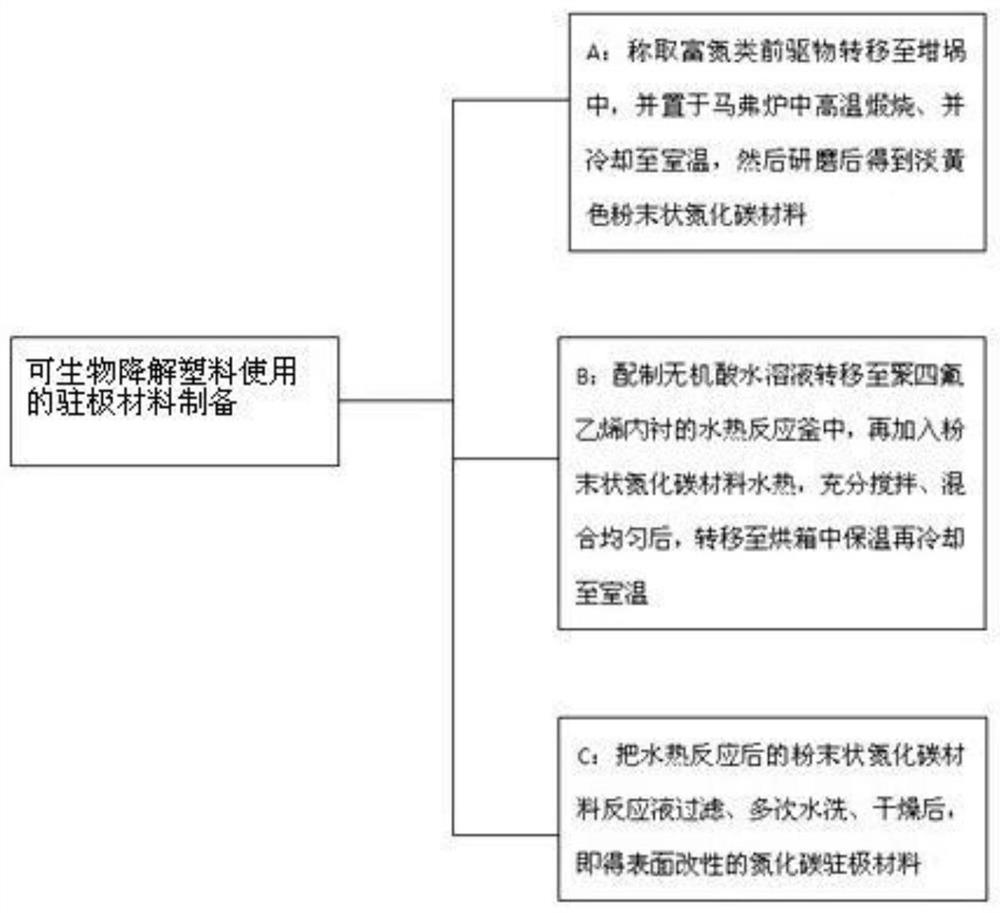

[0018] figure 1 As shown, the electret material used for biodegradable plastics is prepared. The preparation of the electret material uses carbon nitride and inorganic acid as raw materials. The process of preparing the electret material is as follows. A: Weigh the nitrogen-rich precursor and transfer it to the crucible , and placed in a muffle furnace for high-temperature calcination, cooled to room temperature, and ground to obtain a light yellow powder carbon nitride material. Depending on the calcination temperature, the yield of carbon nitride is 40% to 60%; B: The prepared inorganic acid aqueous solution is transferred to a polytetrafluoroethylene-lined hydrothermal reaction kettle, and then powdered carbon nitride material is added to fully After stirring and mixing evenly, transfer to an oven to keep warm and then cool to room temperature. Among them, the inorganic acid includes one of commonly used inorganic acids such as sulfuric acid, hydrochloric acid, nitric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com