Melt-blown polypropylene material with long-acting filtering function and preparation method and application thereof

A melt-blown polypropylene and polypropylene resin technology, applied in the field of melt-blown polypropylene and its preparation, can solve the problem of increasing the charge trapping of melt-blown non-woven fabrics, ineffective development of melt-blown polypropylene non-woven fabrics, and charge attenuation Long-term filtration performance and other issues, to achieve the effect of improving the blockage of die holes by agglomeration, prolonging the electret effect, and enhancing the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

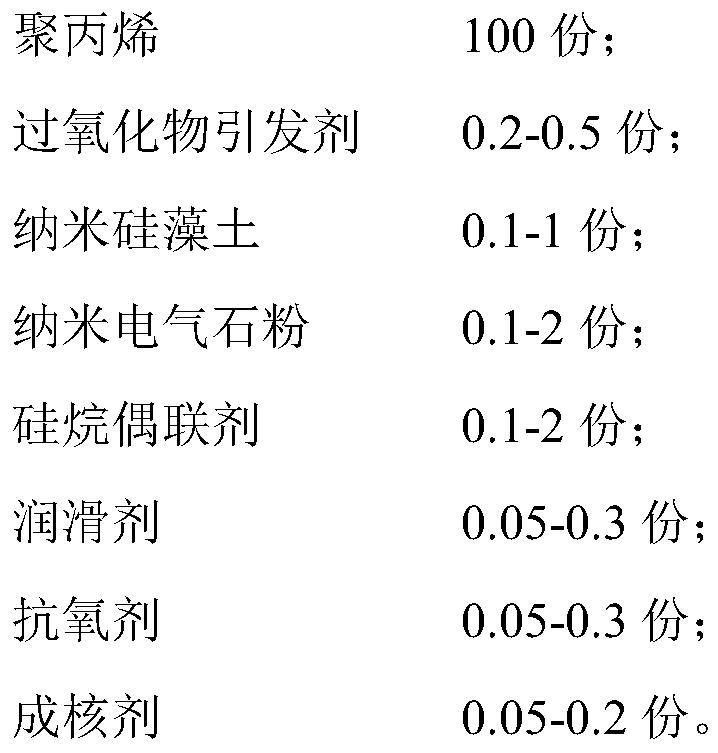

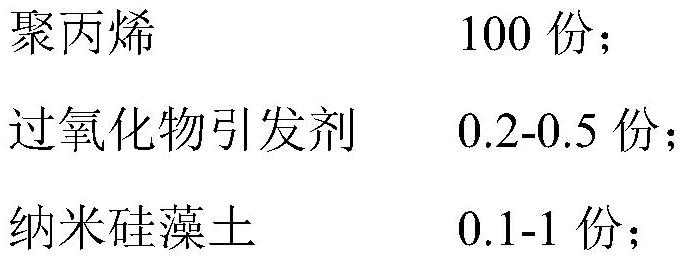

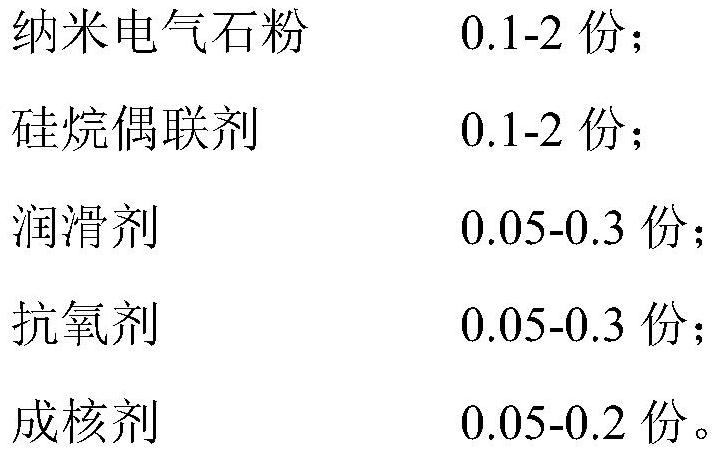

Method used

Image

Examples

Embodiment 1-5

[0036] 1. According to the formula in Table 1, diatomite in Examples 1-5 is added to the diluent respectively, and Examples 1-5 are respectively configured into 1%, 8%, 5%, 2%, and 10% mixed solutions, Pour it into a high-speed mixer with an ultrasonic function and stir, and the ultrasonic frequencies are respectively 15kHZ, 25kHZ, 30kHZ, 30kHZ, and 40kHZ in Examples 1-5, and ultrasonically 5min, 10min, 15min, and 20min respectively in Examples 1-5, 25min for pre-dispersion treatment; according to the formula in Table 1, the nano-tourmaline powder and silane coupling agent in Examples 1-5 were added to the pre-dispersion mixture, and Examples 1-5 were respectively stirred and ultrasonically 10min, 15min, 20min, 25min, 30min, under the action of silane coupling agent, tourmaline powder and diatomite can be fully dispersed and infiltrated, and under the action of ultrasound, nano tourmaline powder enters the pores of diatomite with diluent, and the modified filler mixture is obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com