Polypropylene electret master batch, preparation method thereof and polypropylene melt-blown non-woven fabric

A technology of polypropylene and non-woven fabrics, which is applied in the manufacture of single-component polyolefin rayon, non-woven fabrics, and rayon. It can solve the problems of poor electret effect and poor compatibility, and achieve high yield and high yield. The effect of high fluidity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

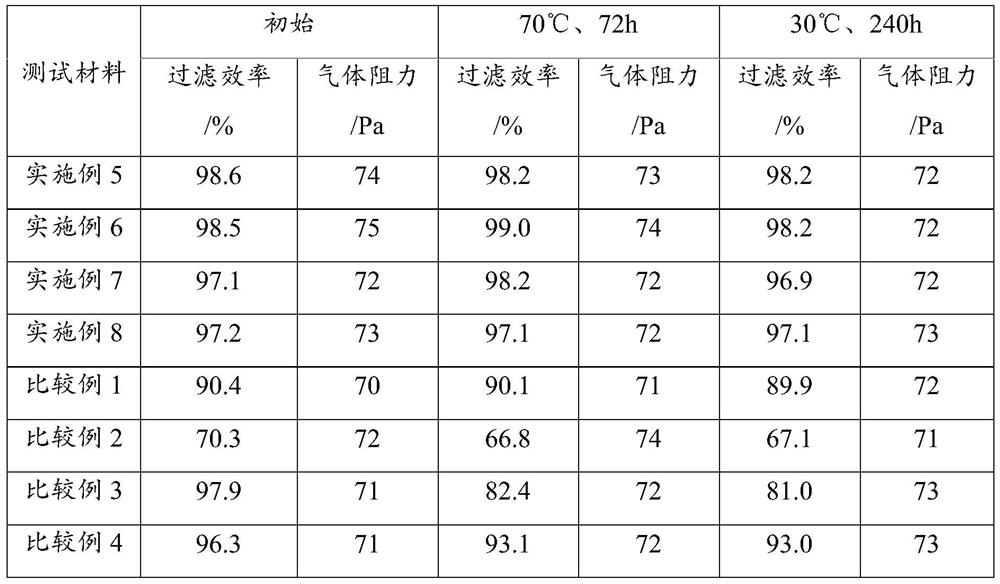

Examples

Embodiment 1

[0050] This embodiment provides polypropylene electret master batches, including the following components in parts by weight:

[0051] 70 parts of polypropylene resin with a melt index of 1200g / 10min, 30 parts of zinc stearate, 2 parts of dibenzylidene sorbitol, 3 parts of maleic anhydride grafted polypropylene with a melt index of 250g / 10min, and 5 parts of polypropylene wax , 0.5 parts of tris(2,4-di-tert-butyl)phenyl phosphite.

[0052] The preparation method of the polypropylene electret masterbatch of the present embodiment, comprises the steps:

[0053] (a) Zinc stearate, dibenzylidene sorbitol and maleic anhydride grafted polypropylene are stirred uniformly to obtain a modified mixture;

[0054] (b) The polypropylene resin is placed in the mixer, and after stirring for 10 minutes, the modified mixture obtained in step (a), polypropylene wax, tris (2,4-di-tert-butyl) phenyl phosphite Add it into the mixer and continue to stir for 30 minutes to obtain the premix;

[00...

Embodiment 2

[0057] This embodiment provides polypropylene electret master batches, including the following components in parts by weight:

[0058] 75 parts of polypropylene resin with a melt index of 1300g / 10min, 25 parts of magnesium stearate, 3 parts of bis(p-methyldibenzylidene)sorbitol, and a maleic anhydride grafted propylene-based elastomer with a melt index of 120g / 10min 2.5 parts, 3.5 parts of polypropylene wax, 1 part of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester.

[0059] The preparation method of the polypropylene electret masterbatch of the present embodiment, comprises the steps:

[0060] (a) Stir magnesium stearate, two (p-methyl dibenzylidene) sorbitol and maleic anhydride grafted propylene-based elastomer to obtain a modified mixture;

[0061] (b) Place the polypropylene resin in a mixer, and after stirring for 10 minutes, sequentially mix the modified mixture obtained in step (a), polypropylene wax, tetrakis[β-(3,5-di-tert-butyl-4 -...

Embodiment 3

[0064] This embodiment provides polypropylene electret master batches, including the following components in parts by weight:

[0065] 80 parts of polypropylene resin with a melt index of 1400g / 10min, 20 parts of aluminum laurate, 4 parts of bis(4-methyldibenzylidene)sorbitol, and methyl methacrylate grafted polypropylene with a melt index of 150g / 10min 2.5 parts, 4 parts of polyethylene wax, 1.5 parts of n-octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate.

[0066] The preparation method of the polypropylene electret masterbatch of the present embodiment, comprises the steps:

[0067] (a) stirring aluminum laurate, bis(4-methyldibenzylidene) sorbitol and methyl methacrylate grafted polypropylene to obtain a modified mixture;

[0068] (b) Place the polypropylene resin in a mixer, and after stirring for 10 minutes, sequentially mix the modified mixture obtained in step (a), polyethylene wax, β-(3,5-di-tert-butyl-4-hydroxy Phenyl) n-octadecanyl propionate was added in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com