Antibacterial polylactic acid melt-blown non-woven fabric

A melt-blown non-woven, polylactic acid technology, applied in non-woven fabrics, textiles and papermaking, conjugated synthetic polymer rayon, etc. problems, to achieve the effect of improving crystallization rate and crystallinity, improving processing performance, and improving antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

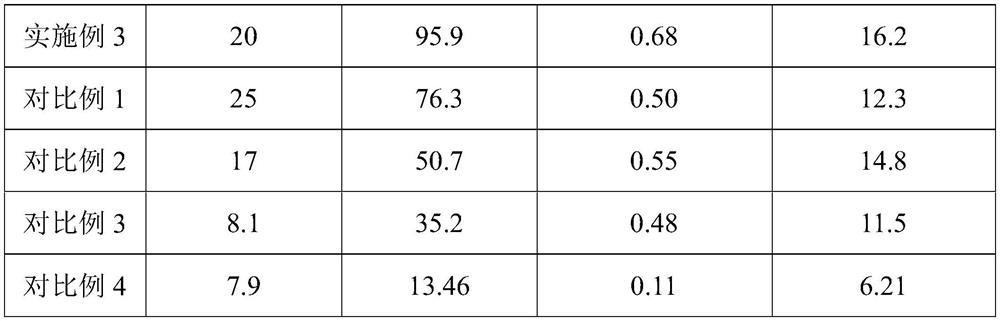

Examples

Embodiment 1

[0021]A antibacterial polylactic acid meltblown nonwoven fabric comprising: polylactic acid 80g, polybutanoicate 20g, phenylphosphate 0.1g, modified montmorillonite 0.4 g, epoxidized corn Oil 5G;

[0022]Among them, in the preparation of modified montmorillonmine, 2.5 g of chitosan was added to a aqueous aqueous aqueous acetic acid in a aqueous acetic acid, and the mixture was stirred at room temperature to dissolve the chitosan solution; add 1G nammond to soil to 100ml Mix mixing in water, static swelling 24 h, then mixed with the chitosan solution, adjusted pH = 4.3 with acetate aqueous sodium acetate, then stirred at 80 ° C for 7 h, filtered, water washing filter cake to give an intermediate material to add concentrations It was stirred at 1 mol / L of a silver nitrate solution, stirred at room temperature for 4 h, filtered, washed with filter cake, and dried under reduced pressure to obtain modified montmorillonite.

Embodiment 2

[0024]A antibacterial polylactic acid meltblown nonwoven fabric comprising: polylactic acid 85g, polybutyl dikaricate 15g, phenylphosphate 0.1g, modified montmorillonite 0.9 g, epoxidized corn Oil 3G;

[0025]Among them, in the preparation of modified montmorillonmine, 3 g of chitosan was added to a aqueous aqueous aqueous solution of 400 ml of mass fraction, stirred at room temperature to dissolve the chitosan solution; 1 g of nammond mandidine was added to 100 ml of water to stir Mixed, static swelling 24 h, then mixed with the chitosan solution, adjusted pH = 4.7 with acetate acetate, then stirred at 70 ° C for 8 h, filtered, water washing cake to obtain an intermediate material; add the concentration of the intermediate material to 0.6 In a silver nitrate solution of Mol / L, it was stirred at room temperature for 5 h, filtered, water washing cake, and dried under reduced pressure to obtain modified montmorillonite.

Embodiment 3

[0027]A antibacterial polylactic acid meltblown nonwoven fabric, a raw material comprising: polylactic acid 82 g, polybutic acid butnectate 18g, phenylphosphate 0.1g, modified montmorillonite 0.7 g, epoxidized corn Oil 4G;

[0028]Among them, in the preparation of modified montmorillonmine, 2.7 g of chitosan was added to aqueous aqueous aqueous aqueous acetic acid, stirred at room temperature to dissolve the chitosan solution; add 1G nammond to soil to 100ml Mix mixing in water, static swelling 24 h, then mixed with the chitosan solution, adjusted pH = 4.5 with acetate acetate, then stirred at 75 ° C, filtered, water washing cake to obtain an intermediate material; In a nitric aqueous solution of 0.8 mol / L, it was stirred at room temperature for 4.5 h, filtered, water washing cake, and dried under reduced pressure to obtain modified montmorillonite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com