Melt-blown polypropylene electret master batch and preparation method thereof

A technology of melt-blown polypropylene and polypropylene, which is applied in the field of melt-blown polypropylene electret masterbatch and its preparation, can solve the problems of poor dispersion of fluorine-containing polymers, achieve high filtration efficiency, obvious electret effect, and a preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A melt-blown polypropylene electret masterbatch material, by weight, comprises the following components:

[0036] Random copolymer polypropylene (melt index 1000g / 10min) 86.3 parts

[0037] 10 parts of modified polytetrafluoroethylene

[0038] Maleic anhydride grafted polypropylene 2 parts

[0039] Antioxidant 1010 0.2 parts

[0040] Anti-ultraviolet agent UV-531 1.5 parts

[0041] A preparation method of melt-blown polypropylene master batch material, comprising the following steps:

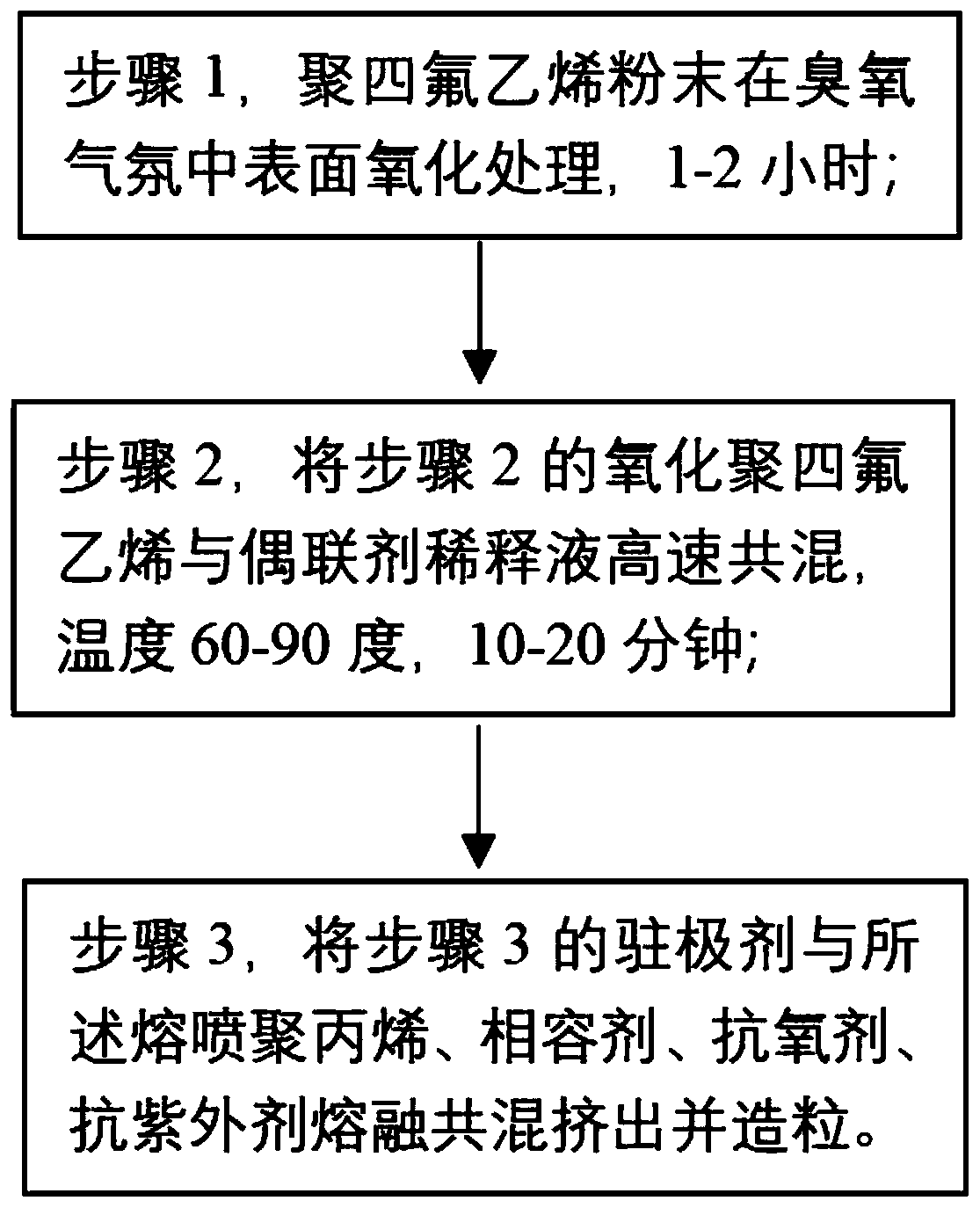

[0042] Step 1, the surface oxidation of the polytetrafluoroethylene powder is carried out in an ozone atmosphere, and the oxidation time is 1-2 hours;

[0043] Step 2, blending the surface-oxidized polytetrafluoroethylene powder with a coupling agent to obtain an electret, the blending temperature is 60°C to 90°C, and the blending time is 10-20min;

[0044] In step 3, the electret in step 2 is melt-blended and extruded with the melt-blown polypropylene, compatibilizer, antioxidant an...

Embodiment 2

[0047] A melt-blown polypropylene electret masterbatch material, by weight, comprises the following components:

[0048] Random copolymer polypropylene (melt index 1000g / 10min) 81.3 parts

[0049] 15 parts of modified polytetrafluoroethylene

[0050] Maleic anhydride grafted polypropylene 2 parts

[0051] Antioxidant 1010 0.2 parts

[0052] Anti-ultraviolet agent UV-531 1.5 parts

[0053] The preparation method of melt-blown polypropylene masterbatch material, the steps are the same as those in Example 1.

Embodiment 3

[0055] A melt-blown polypropylene electret masterbatch material, by weight, comprising the following components: random copolymerized polypropylene (melting index 1000g / 10min) 68.3 parts of modified polytetrafluoroethylene 28 parts of maleic anhydride grafted polymer Propylene 2 parts Antioxidant 1010 0.2 parts Anti-ultraviolet agent UV-531 1.5 parts

[0056] The preparation method of melt-blown polypropylene masterbatch material, the steps are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com