Plugging material used for oil base drilling fluid, and preparation method thereof

An oil-based drilling fluid and plugging material technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems that affect the safety and speed of drilling engineering, the oil-based drilling fluid is expensive, and prolong the drilling and well construction period. and other problems, to achieve the effect of good suspension stability, low density and good lipophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

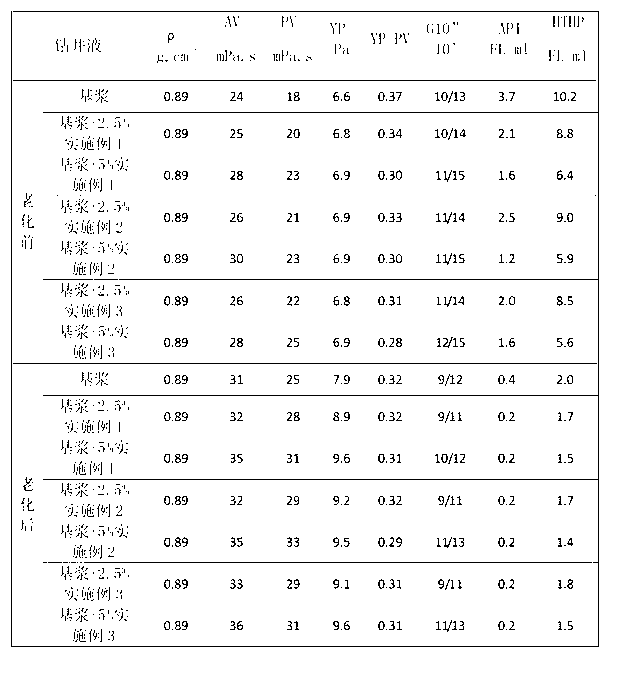

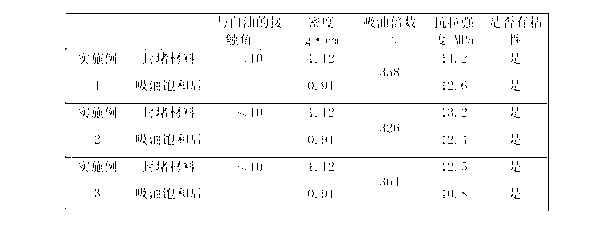

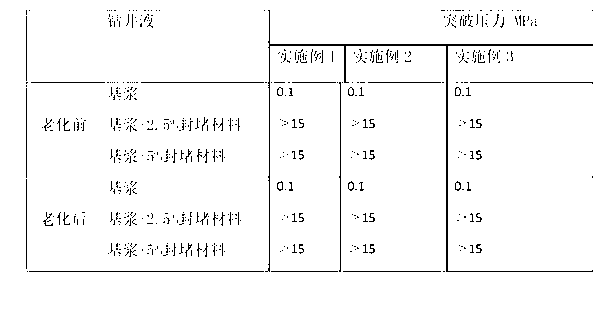

Examples

Embodiment 1

[0067] A preparation method of plugging material for oil-based drilling fluid:

[0068] (1) Dissolve 1.8g of dispersant polyvinyl alcohol in 180ml of distilled water at 80°C;

[0069] (2) Add 15g of butyl acrylate, 15g of octadecyl acrylate, 15g of butyl methacrylate, 7g of styrene, and 8g of acrylonitrile into (1), and stir at a high speed of 3000r / min to form a uniform and stable dispersion system;

[0070] (3) Add 3g of porogen ethyl acetate, 0.1g of crosslinking agent divinyl styrene, and 0.1g of initiator benzoyl peroxide to the dispersion system obtained in (2), and stir the above mixed solution with a mixer for 10min to make fully dissolved in the system;

[0071] (4) Put the above liquid into a 500ml wide-mouth Erlenmeyer flask, protect it with nitrogen, put it in a water bath at 80±5°C and heat it, and react for 8 hours to obtain the preliminary product;

[0072] (5) Washing of the product: Wash the product with 70-80°C water to remove excess impurities;

[0073] (...

Embodiment 2

[0075] A preparation method of plugging material for oil-based drilling fluid:

[0076] (1) Dissolve 0.9g sodium lauryl sulfate and 0.9g polyethylene glycol in 180ml distilled water at 80°C;

[0077] (2) Add 20g ethyl acrylate, 20g stearyl acrylate, 5g methyl methacrylate, 5g stearyl methacrylate, 10g stilbene into (1), stir at 3000r / min at high speed to form a uniform and stable decentralized system;

[0078] (3) Add 3g of porogen toluene, 0.1g of crosslinking agent divinylstyrene, 0.1g of azobisisoheptanonitrile to the dispersion system obtained in (2), and stir the above mixture with a mixer for 10min to fully dissolve it. in the system;

[0079] (4) Put the above liquid into a 500ml wide-mouth Erlenmeyer flask, protect it with nitrogen, put it in a water bath at 80±5°C and heat it, and react for 8 hours to obtain the preliminary product;

[0080] (5) Washing of the product: Wash the product with 70-80°C water to remove excess impurities;

[0081] (6) After the product ...

Embodiment 3

[0083] A preparation method of plugging material for oil-based drilling fluid:

[0084] (1) Dissolve 0.9g polyacrylamide and 0.9g polyvinyl alcohol in 180ml distilled water at 80°C;

[0085] (2) Add 30g methyl acrylate, 10g octadecyl acrylate, 10g ethyl methacrylate, 5g butyl methacrylate, 2g stilbene and 3g butadiene to (1), stir at 3000r / min, Form a uniform and stable dispersion system;

[0086] (3) Add 3g of paraffin wax, 0.1g of crosslinking agent silicone crosslinking agent WD-20, 0.02g of potassium persulfide and 0.08g of tert-butyl hydroperoxide to the dispersion system obtained in (2), and stir the above mixture with a mixer solution for 10 minutes to fully dissolve it in the system;

[0087] (4) Put the above liquid into a 500ml wide-mouth Erlenmeyer flask, protect it with nitrogen, put it in a water bath at 80±5°C and heat it, and react for 8 hours to obtain the preliminary product;

[0088] (5) Washing of the product: Wash the product with 70-80°C water to remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com