Biological membrane-activated sludge composite membrane bioreactor for denitrification and water treatment method using same

A bioreactor and activated sludge technology, applied in the field of water treatment, can solve the problems of affecting the mass transfer of the medium, affecting the effect of denitrification, and increasing operating costs, so as to enhance the mass transfer efficiency, avoid short circuits, and reduce land occupation. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

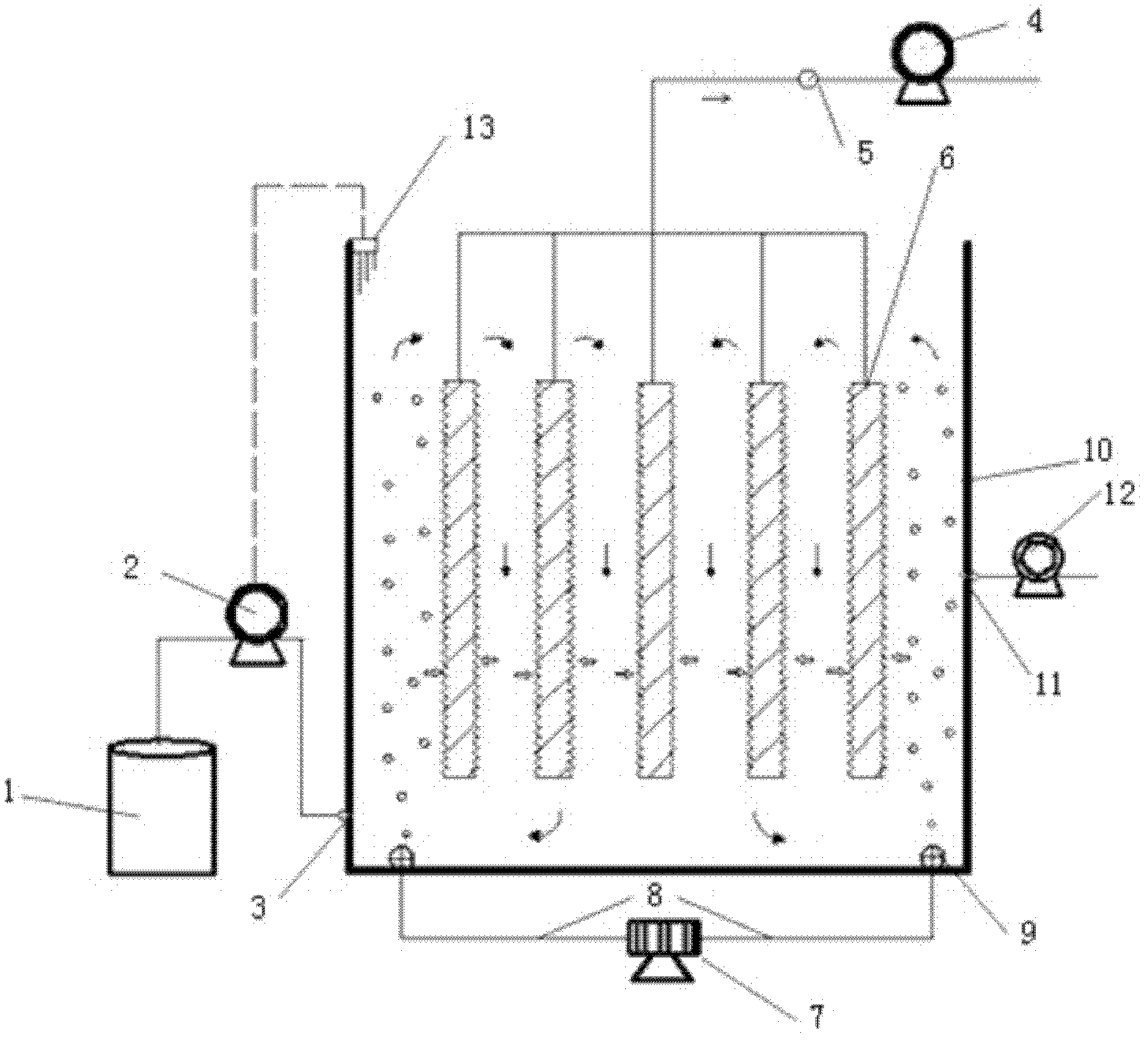

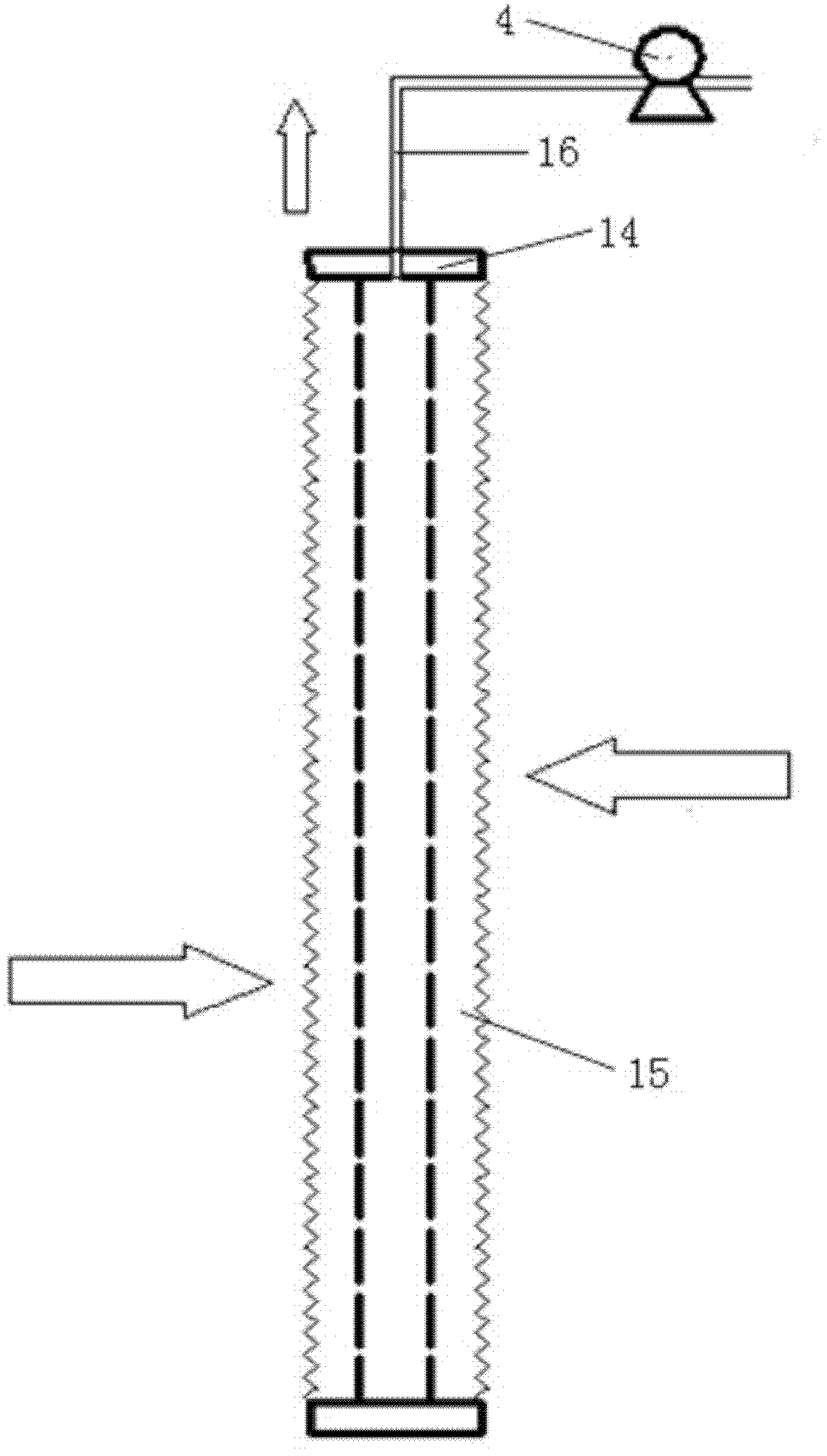

[0038] The schematic diagram of the device in this embodiment is figure 1 with figure 2 As shown, figure 1 In the middle, the solid arrow indicates the direction of the suspended sludge flow in the reaction tank, and the hollow arrow indicates the direction of the membrane outlet. figure 2 In the middle, the arrow indicates the direction of the membrane.

[0039] The reaction tank 10 has an effective volume of 16L and is made of organic glass. The internal length is 29cm, the internal width is 19cm, and the liquid level is 30cm high. 5 membrane modules 6 are placed in balance inside, the membrane modules are 19cm long, 1.5cm wide, and 26cm high. The distance between the membrane modules is 4cm. The water inlet pump 2 is controlled by a level gauge 13. There are two microporous aeration pipes on both sides of the reaction tank, and the aeration volume is 10-15m 3 / h. The water outlet is continuous water with a flow rate of 1.5L / h. 800mL of sludge is discharged regularly eve...

Embodiment 2

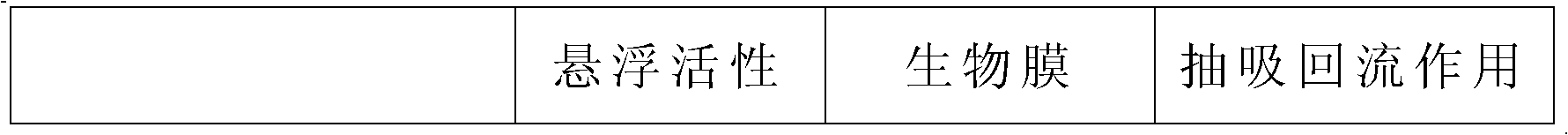

[0041] The composite membrane bioreactor constructed in Example 1 was used to investigate the coupling effect between suspended activated sludge and biofilm. Under the same conditions, the batch test of suspended activated sludge, biofilm and biofilm nitrification and denitrification under the action of suction and reflux were carried out. The experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com