A treatment device and method for printing desizing mixed wastewater

A technology of mixed wastewater and treatment methods, applied in textile industry wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problem of increasing the difficulty and cost of comprehensive printing and dyeing wastewater treatment, difficult to achieve standard discharge, and impossible to achieve Effectively deal with other problems, achieve good sludge retention performance, reduce comprehensive operating costs, and high impact load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

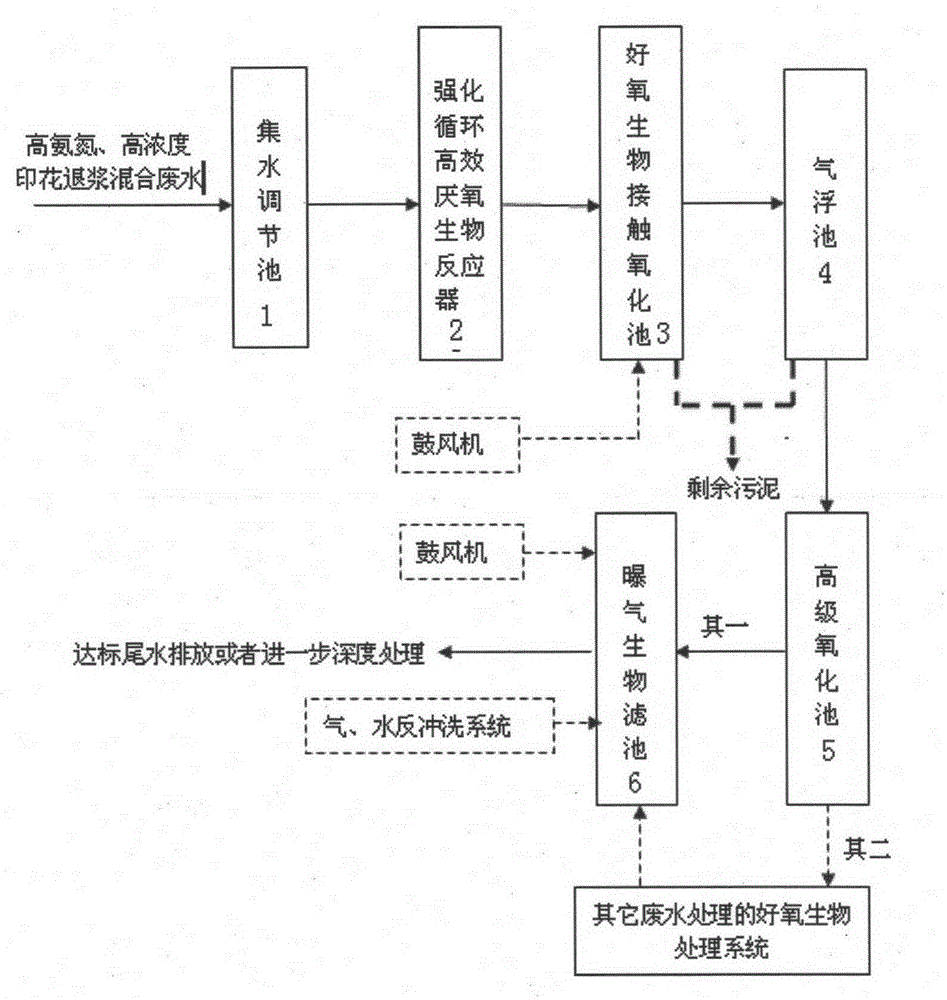

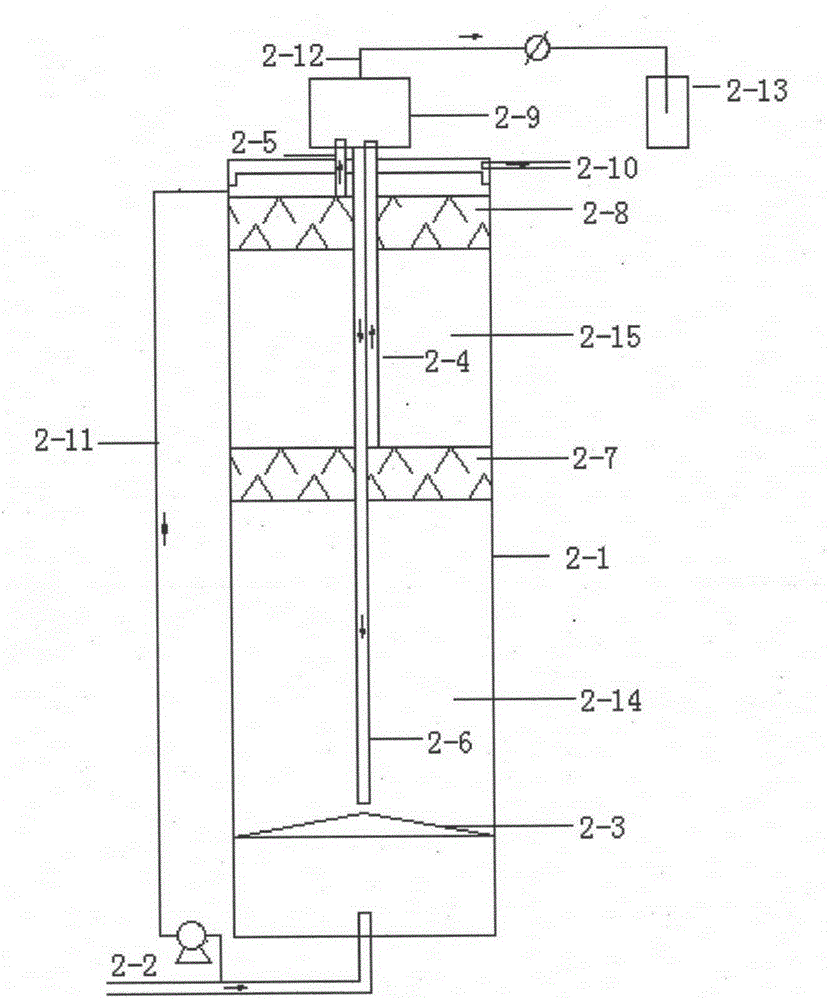

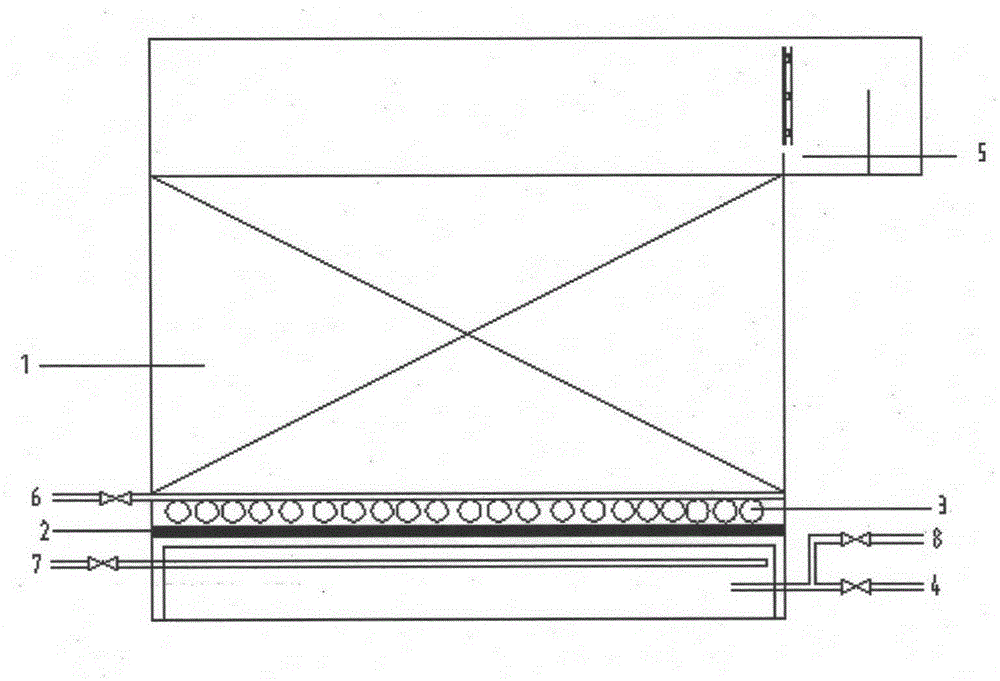

[0032] like figure 1 As shown, it is a schematic structural diagram of a treatment device for printing desizing mixed wastewater. The described treatment device for printing desizing mixed wastewater includes a water collection adjustment tank 1, an enhanced circulation high-efficiency anaerobic bioreactor 2, and an aerobic biological contact oxidation tank 3. Air flotation tank 4, advanced oxidation tank 5 and biological aerated filter tank 6. The specific steps of using the above-mentioned printing and desizing mixed wastewater treatment device to carry out the printing and desizing mixed wastewater treatment method are as follows: sequentially use the printing and desizing mixed wastewater with the water collection adjustment tank 1, the enhanced circulation high-efficiency anaerobic bioreactor 2, and the aerobic Biological contact oxidation tank 3, air flotation tank 4, advanced oxidation tank 5 and aerobic biological treatment system are used for treatment, and the result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com