Method for processing sewage by multilevel vertical-current compound manual wetting ground and processing system thereof

A technology of constructed wetlands and treatment systems, applied in the direction of water/sewage multi-stage treatment, aerobic and anaerobic process treatment, sustainable biological treatment, etc., can solve the problem of small area of treatment costs, to prevent pipeline blockage, The effect of improving the removal effect and improving the removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

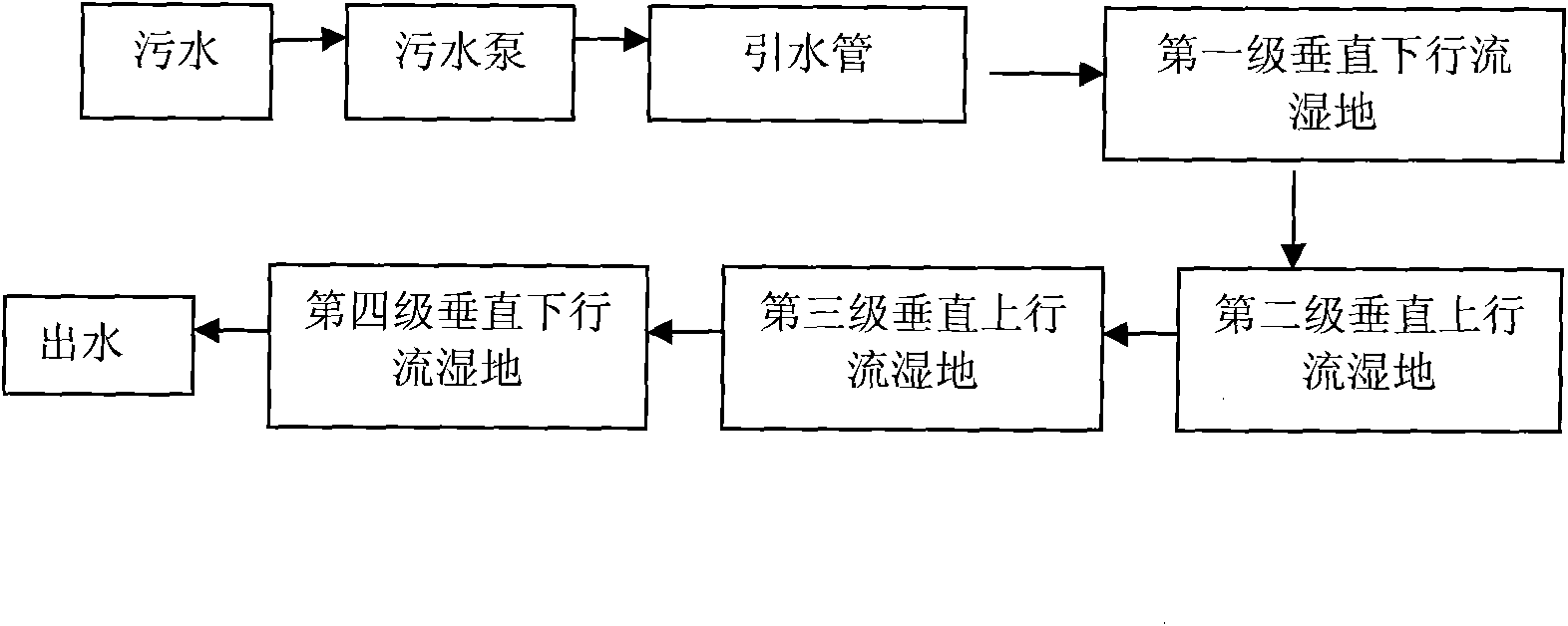

[0028] The four-stage vertical flow compound constructed wetland treatment system of the present invention consists of four parts: "one-stage vertical downflow wetland unit + two-stage vertical upflow wetland unit + three-stage vertical upflow wetland unit + four-stage vertical downflow wetland unit".

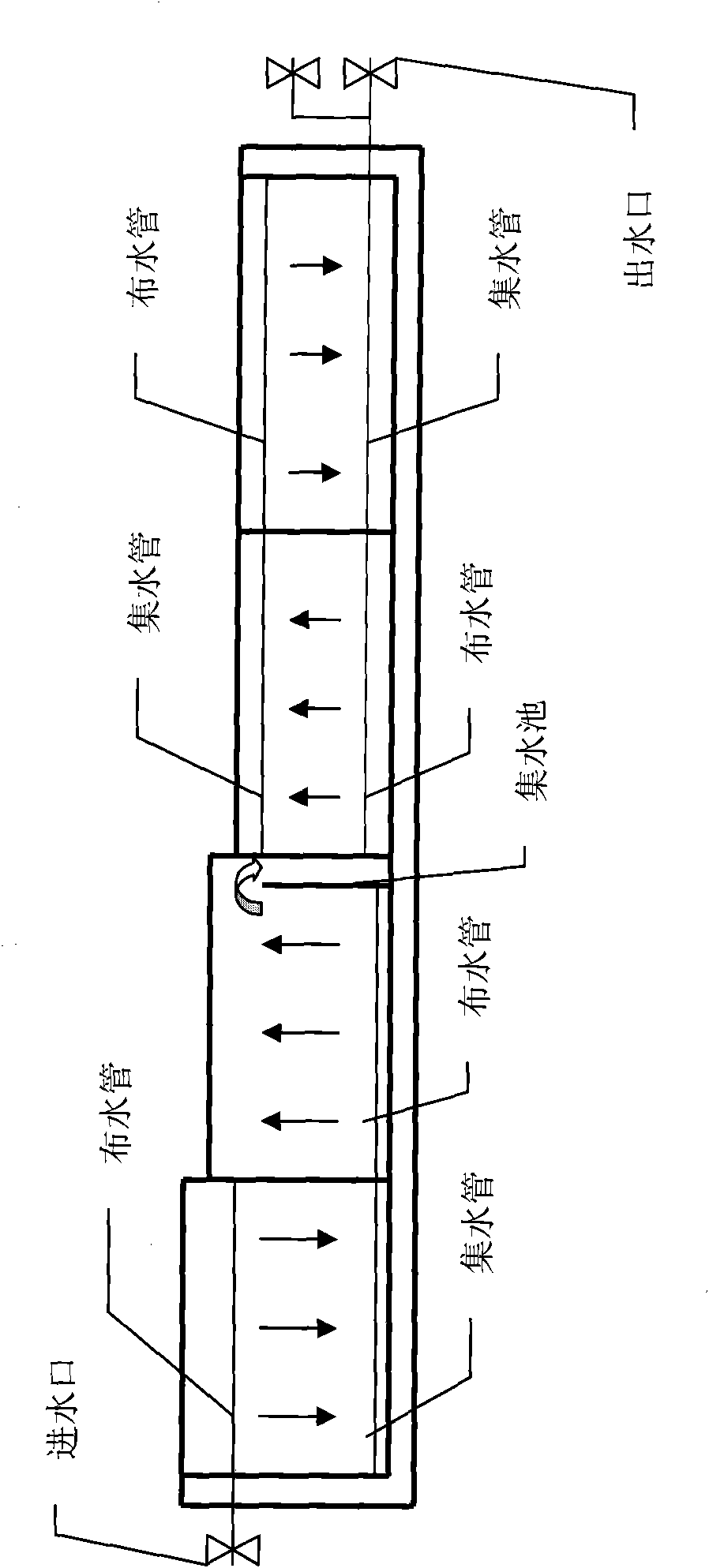

[0029] The river sewage is lifted by the pump to the first-level vertical downflow wetland unit, and the sewage is evenly distributed in the first-level vertical downflow artificial wetland through the "king"-shaped water distribution pipe on the top of the first-level vertical downflow artificial wetland, and then passed through the treatment medium The percolation reaches the bottom, and the sewage after the first-level vertical downflow treatment is connected to the bottom water distribution pipe of the second-level vertical upflow constructed wetland unit by the bottom water collection pipe. Utilizing the adsorption properties of the matrix and atmospheric pressure, the sewa...

Embodiment 2

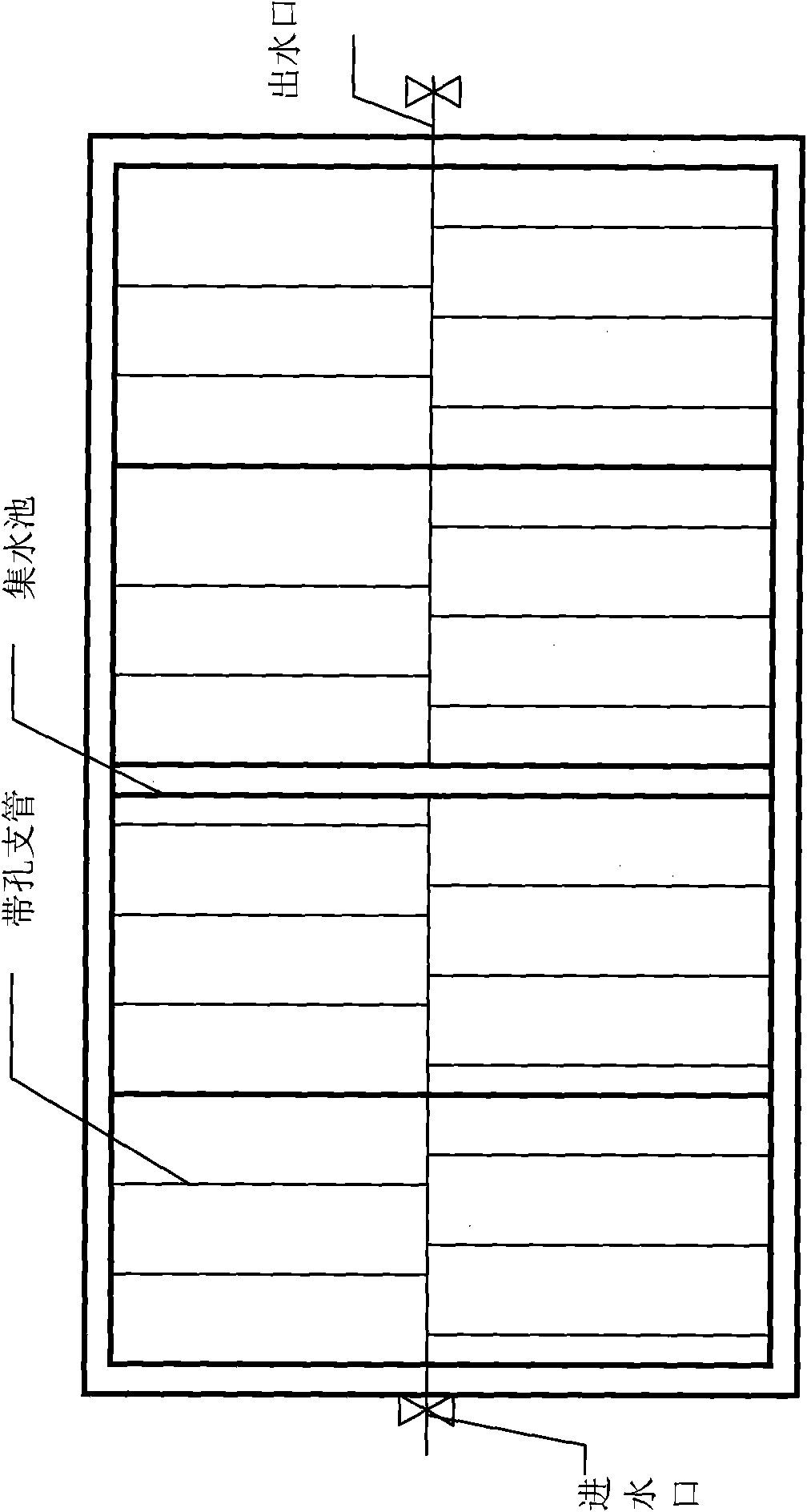

[0041] The composite vertical downflow constructed wetland system consists of two vertical downflow wetland units connected in series, a bed body and a water collection pipe. The bed wall of the bed body is a brick structure with cement plaster, and the bottom is a concrete structure. The length × width × height of the first-stage vertical downflow constructed wetland of the composite vertical downflow constructed wetland treatment system is 8m×8m×1.6m, and the length×width×height of the second-stage vertical downflow artificial wetland is 8m× 8m x 1.4m. The drop between the first and second wetland units is 20cm.

[0042] The sewage from the Dongguan Canal is pumped up into the "king"-shaped water distribution pipe on the top of the first-stage wetland of the composite vertical downflow artificial wetland, and the sewage is evenly distributed in the first-stage vertical downflow artificial wetland, and then reaches the bottom through the percolation of the treatment medium ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com