Hybridized composite reverse osmosis membrane containing carbon nano tubes and preparation method thereof

A technology of reverse osmosis composite membrane and carbon nanotubes, which is applied in the field of hybrid reverse osmosis composite membrane and its preparation, can solve the problems of reducing membrane rejection rate and difficult to achieve fundamental changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of aqueous phase solution A: dissolving and dispersing m-phenylenediamine and multi-walled carbon nanotubes in water, ultrasonicating for a period of time to make them disperse evenly, and preparing m-phenylenediamine with a mass percentage concentration of 2%, more An aqueous phase solution A with a mass percent concentration of walled carbon nanotubes of 0.005%;

[0035] (2) Preparation of organic phase solution B: dissolving trimesoyl chloride in n-hexane, and ultrasonically stirring to prepare an organic phase solution B with a mass percent concentration of trimesoyl chloride of 0.2%;

[0036] (3) Immerse the polysulfone support membrane in the aqueous phase solution A for 20 minutes to remove the aqueous phase solution remaining on the surface of the polysulfone support membrane, then immerse the bottom membrane in the organic phase solution B and maintain it for 40 seconds to remove the remaining residue on the surface of the membrane. The organic ...

Embodiment 2-3

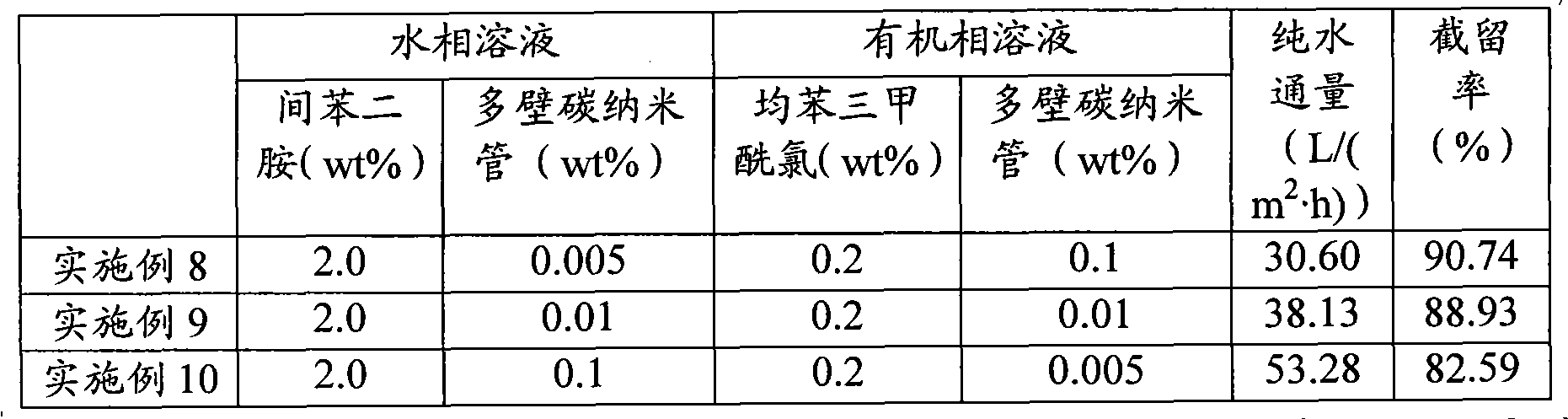

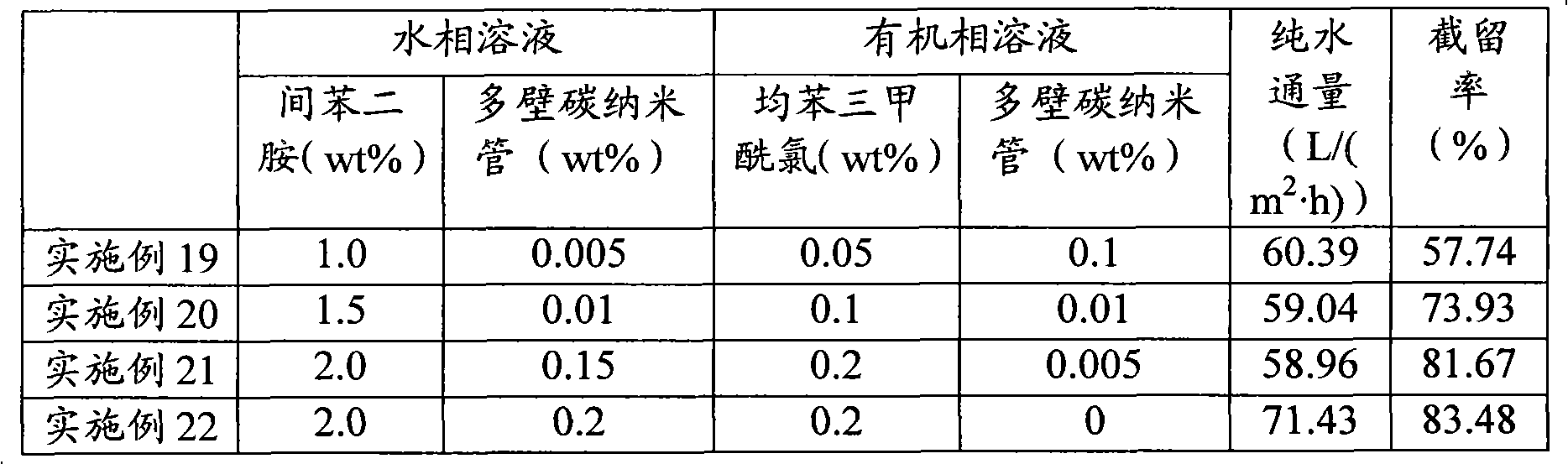

[0040] Except that the concentration of multi-walled carbon nanotubes in the aqueous solution A is adjusted, all the other operations are the same as in Example 1, and a hybrid reverse osmosis composite membrane containing carbon nanotubes is prepared, and the prepared hybrid reverse osmosis composite membrane The performance test results are shown in Table 1.

Embodiment 4-7

[0049] (1) Preparation of aqueous phase solution A: dissolving and dispersing m-phenylenediamine in water, ultrasonicating for a period of time to make it uniformly dispersed, and preparing aqueous phase solution A;

[0050] (2) Preparation of organic phase solution B: dissolving trimesoyl chloride and multi-walled carbon nanotubes in n-hexane, ultrasonic stirring, and preparing organic phase solution B;

[0051] The rest of the operations were the same as in Example 1 to prepare a hybrid reverse osmosis composite membrane containing carbon nanotubes. The performance test results of the prepared hybrid reverse osmosis composite membrane are shown in Table 2.

[0052] Table 2

[0053]

trimesoyl chloride

(wt%)

Multi-walled carbon nano

Tube (wt%)

pure water flux

(L / (m 2 h))

(%)

Example 4

0.2

0.005

27.42

91.38

Example 5

0.2

0.01

34.56

89.34

Example 6

0.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com