Method for preparing loose nanofiltration membrane based on interfacial polymerization

A technology of interfacial polymerization and nanofiltration membranes, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve membrane wetting and other problems, and achieve the effects of improving permeability, stability, and high retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

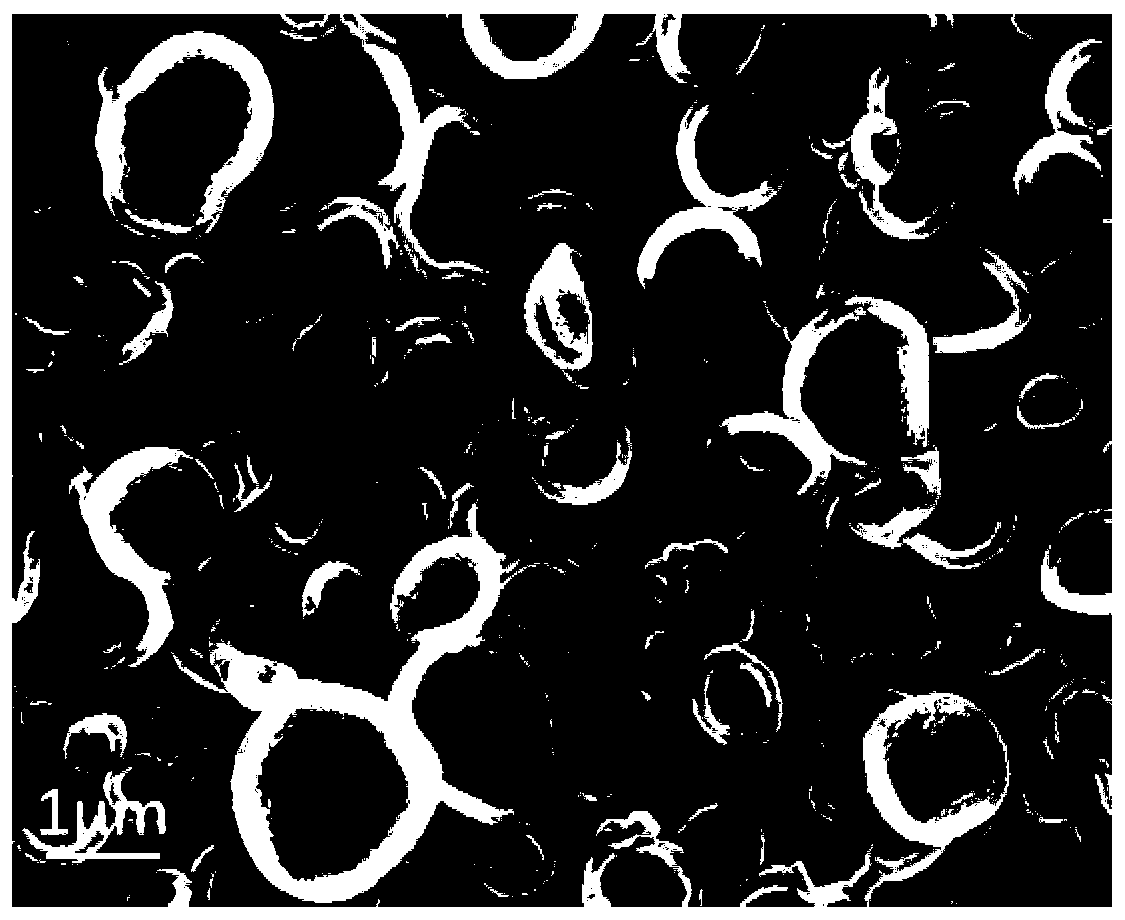

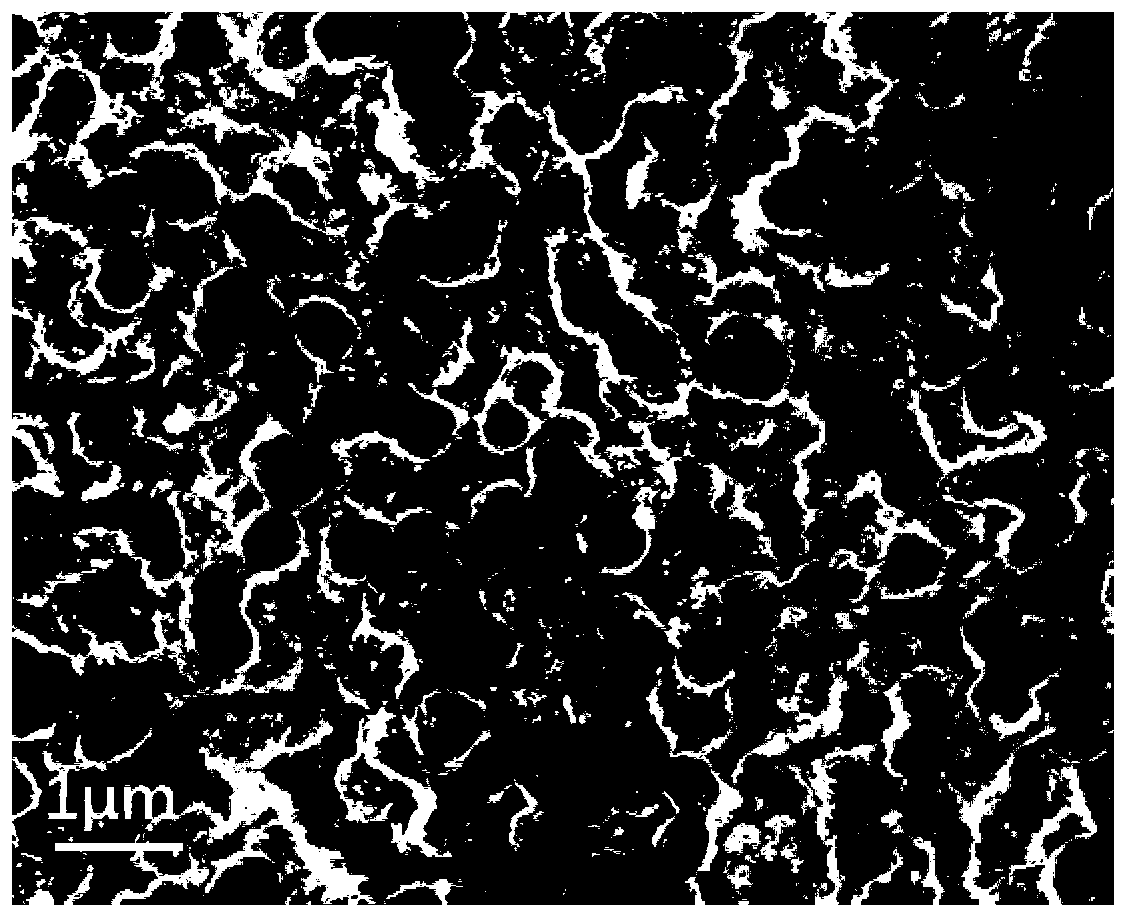

[0027] Take 12.9ml polyethylene glycol-400 and add it to 85ml N-methylpyrrolidone, make it mix well. Then add 19g of PVDF to the above solution while stirring, stir for 10 hours in a water bath at a constant temperature of 60°C to dissolve the polymer completely, and leave it at room temperature for 12 hours to obtain a homogeneous casting solution after defoaming; scrape the casting solution with a scraper Prepare a flat support film on a clean glass plate, stay in the air for 30s, then place the scraped flat support film in a deionized water coagulation bath until it solidifies into a PVDF flat support film; soak the film in deionized water for 24h, during Constantly replace the deionized water to completely remove the residual solvent in the membrane. Weigh 2g of piperazine and dissolve it in 100ml of deionized water to prepare a water-phase monomer, then disperse 0.1g of nanometer silicon dioxide into the above-mentioned water-phase monomer solution, and sonicate for 30min...

Embodiment 2

[0030] Take 10.2ml polyethylene glycol-600 and add it to 165ml N,N-dimethylformamide, make it mix well. Then add 40g of PSF into the above solution while stirring, stir for 12 hours in a water bath at a constant temperature of 70°C to dissolve completely, and let stand at room temperature for 12 hours to obtain a uniform casting solution after defoaming; use a spatula to cast PSF into a film Prepare a flat support film on a clean PTFE plate with liquid scraping, stay in the air for 10s, and then place the scraped flat support film in a deionized water coagulation bath until it solidifies into a PSF flat support film; put the film in deionized water Soak for 24 hours, during which the deionized water was constantly replaced to completely remove the residual solvent in the membrane. Weigh 1.5g of m-phenylenediamine and dissolve it in 100ml of deionized water to obtain a water phase monomer, then disperse 0.05g of graphene oxide nanosheets into the above water phase monomer solut...

Embodiment 3

[0033] Take 5g of polyvinylpyrrolidone and dissolve it in 81ml of N,N-dimethylacetamide, after it is completely dissolved, add 10g of PES into the above solution while stirring, and stir for 10 hours at a water bath temperature of 80°C to make it completely dissolve , standing at room temperature for 12 hours to obtain a uniform casting solution; use a scraper to scrape the PES casting solution on a clean PTFE plate to prepare a flat support film, stay in the air for 30s, and then scrape the scraped flat support film Place it in a deionized water coagulation bath until it solidifies into a PES flat support film; soak the film in deionized water for 24 hours, during which the deionized water is constantly replaced to completely remove the residual solvent in the film. Weigh 0.025g of p-phenylenediamine and dissolve it in 100ml of deionized water to prepare a water phase monomer, then disperse 5g of montmorillonite nanoparticles into the above water phase monomer solution, and ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com