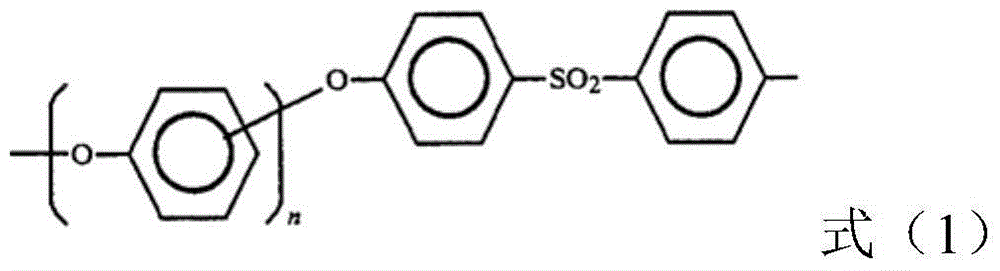

Nanofiltration membrane as well as preparation method and application thereof

A nanofiltration membrane and support layer technology, applied in the field of nanofiltration membranes, can solve the problems of salt rejection and poor water permeability, and achieve the effects of high water flux and excellent acid and alkali corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

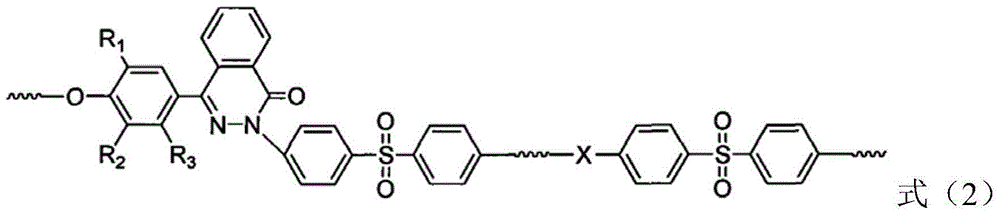

[0042] The preparation method of nanofiltration membrane provided by the invention comprises:

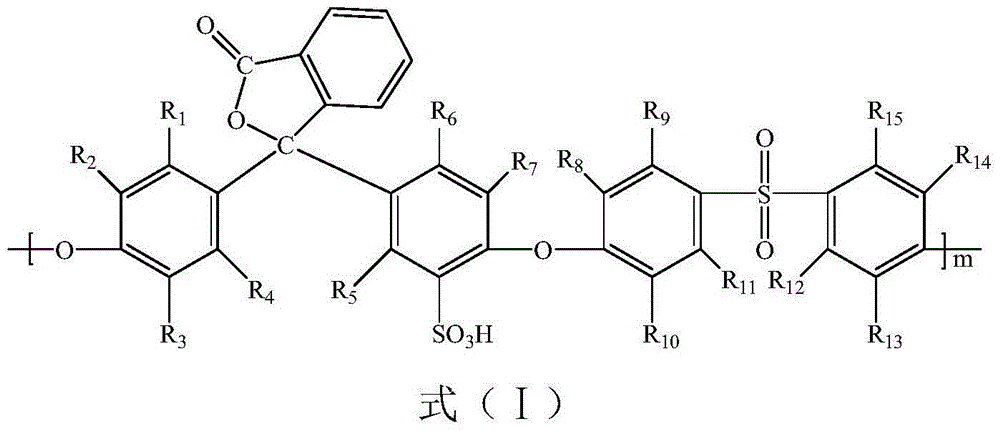

[0043] The negatively charged support layer is sequentially and alternately contacted at least once with a solution containing a cationic polymer and a solution containing an anionic polymer to form at least one layer on the negatively charged support layer comprising sequentially stacked polycation layers and The separation layer of the polyanionic layer, wherein the anionic polymer is a sulfonated polyarylethersulfone having a structure represented by formula (I) and / or formula (II); or,

[0044] The positively charged support layer is sequentially and alternately contacted at least once with a solution containing an anionic polymer and a solution containing a cationic polymer to form at least one layer comprising sequentially stacked polyanions on the positively charged support layer. layer and the separation layer of the polycation layer, wherein the anionic polymer is a sulfona...

Embodiment 1

[0073] This example is used to illustrate the nanofiltration membrane provided by the present invention and its preparation method.

[0074] Chitosan quaternary ammonium salt (purchased from Nantong Lvshen Biological Engineering Co., Ltd., brand NACC) was dissolved in deionized water to prepare a solution containing a cationic polymer with a mass concentration of 0.2%; the sulfonated polyarylether Sulfone C-SPAES (purchased from Tianjin Yanjin Technology Co., Ltd., has the structure shown in formula (Ⅲ), R 1 -R 15 H, m is 60, ion exchange capacity is 1.49mmol / g) dissolved in the mixed solution of N,N-dimethylformamide and water (the volume ratio of N,N-dimethylformamide and water is 1:100, the same below), prepared into a solution containing anionic polymer with a mass concentration of 0.2%.

[0075] The polyacrylonitrile ultrafiltration membrane (purchased from Hangzhou Meiyi Membrane Technology Co., Ltd., with a thickness of 125um, the same below) was soaked in NaOH aqueou...

Embodiment 2

[0078] This example is used to illustrate the nanofiltration membrane provided by the present invention and its preparation method.

[0079] Polyaniline (purchased from Bailingwei Technology Co., Ltd., brand 81303) was dissolved in deionized water to prepare a solution containing a cationic polymer with a mass concentration of 0.2%; sulfonated polyarylethersulfone C-SPAES (purchased from Tianjin Yanjin Technology Co., Ltd. has the structure shown in formula (Ⅲ), R 1 -R 15 is H, m is 80, and the ion exchange capacity is 1.37mmol / g) is dissolved in a mixed solution of N,N-dimethylformamide and water to prepare a solution containing an anionic polymer with a mass concentration of 0.2%.

[0080] Soak the polyacrylonitrile ultrafiltration membrane in NaOH aqueous solution with a concentration of 5% by weight for 3 hours to hydrolyze the cyano groups into carboxyl groups. Fix the treated polyacrylonitrile ultrafiltration membrane in the tetrafluoromembrane with the membrane facing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com