Nano membrane aerobic composting device for livestock manure

A technology for aerobic composting, livestock and poultry manure, applied in fertilization devices, organic fertilizers, excretion fertilizers, etc., can solve the problems of complex operation, constant breeding environment for mosquitoes and flies, and large diffusion of nutrient leaching and odor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

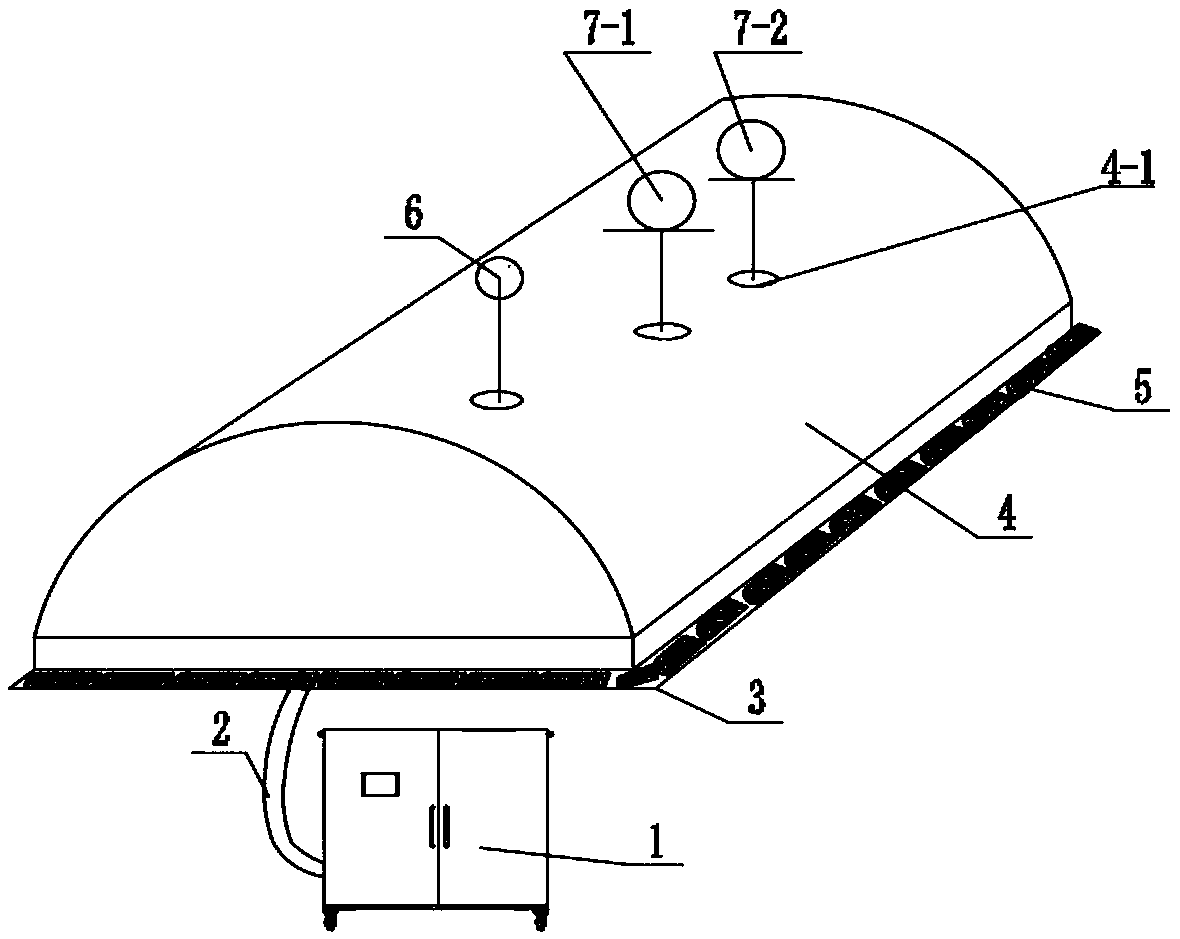

[0114] Embodiment 1: Animal manure nano-film aerobic composting device of the present invention

[0115] The implementation mode of this embodiment is as follows:

[0116] The specific structure of the livestock and poultry manure nano-membrane aerobic composting device can be found in the attached figure 1 , 2 , 3 and attached Figure 4. It includes an anti-seepage layer (3), a host (1), an air supply pipe (2), a composite nano-membrane (4), a sealing device (5), a multi-point temperature sensor (6), a moisture content sensor (7 -1) and the oxygen concentration sensor (7-2);

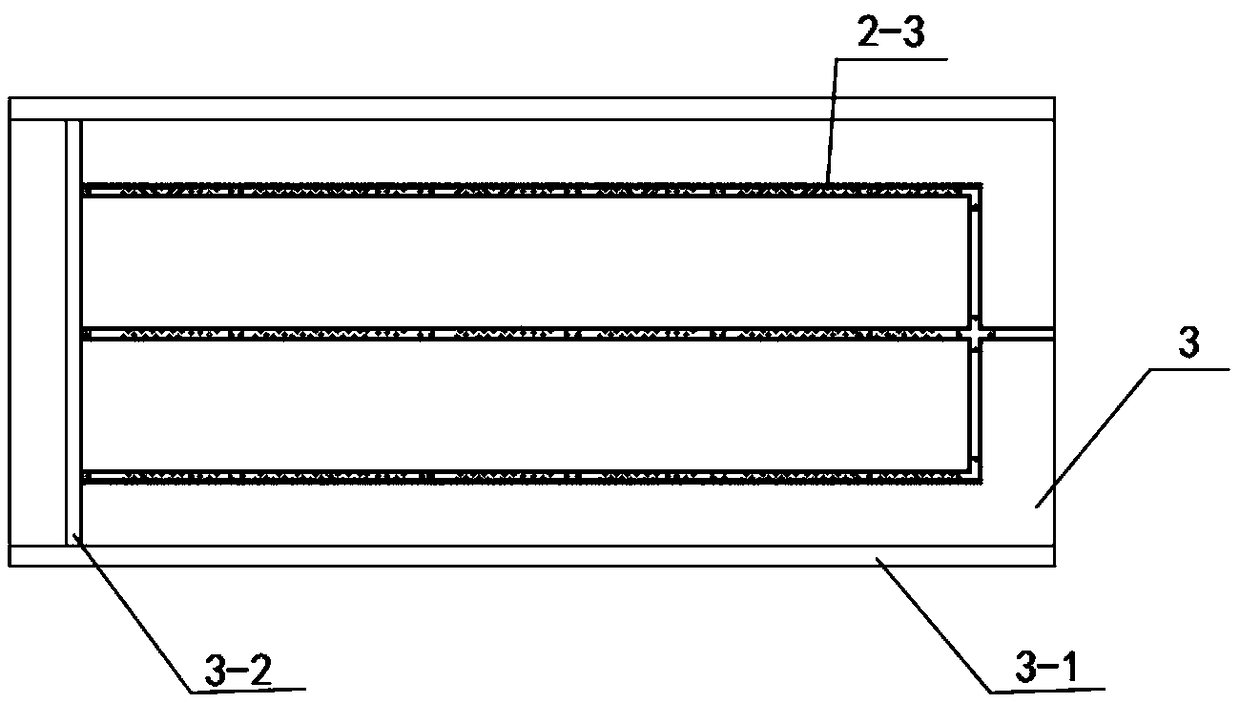

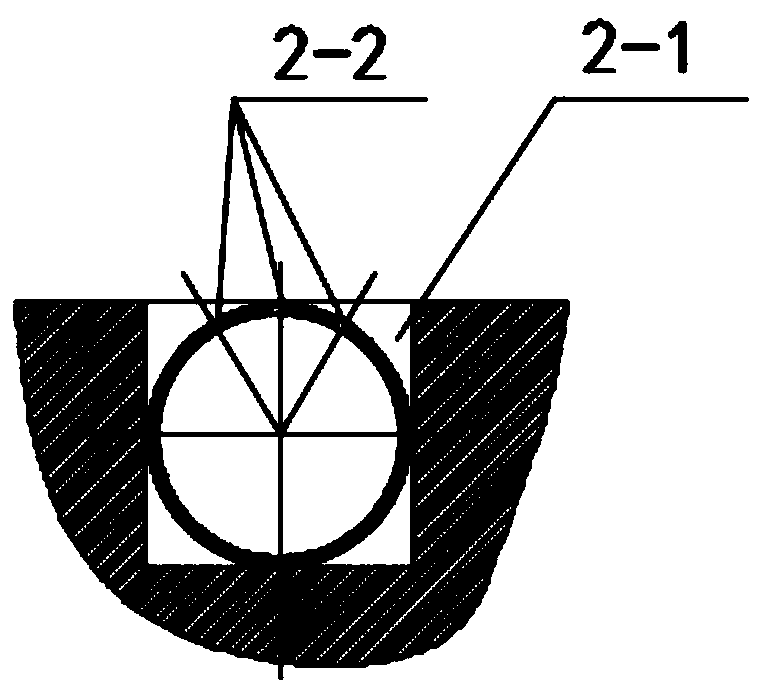

[0117] The anti-seepage layer (3) is a layer of concrete layer with a thickness of 17cm laid with an anti-seepage film made of high-density polyethylene material, and rainwater diversion grooves (3-1) are arranged around the edges of the anti-seepage layer (3) , and the end of the air supply pipe (2) away from the main engine (1) is provided with a leachate tank (3-2), and the upper part of the ant...

Embodiment 2

[0136] Embodiment 2: Animal manure nano-film aerobic composting device of the present invention

[0137] The implementation of this embodiment is the same as Example 1, except that the anti-seepage layer (3) is a ceramsite compacted layer with a thickness of 20cm that is laid with an anti-seepage film made of high-density polyethylene material; near the main frame (1 ) at one end of the anti-seepage layer (3) is higher than the end away from the main engine (1), and the angle between the bottom surface of the anti-seepage layer (3) and the ground is 4°; the upward pipe wall of the air supply pipe (2) is lower than the anti-seepage layer (3) The upper surface is 2.0 mm; the air supply pipe grooves (2-1) of the anti-seepage layer (3) are 5 rectangular pipe grooves; 5 sealing covers or sealing plugs are arranged on the composite nano-membrane (4) The detection hole (4-1);

[0138] Composite nano film (4) has the following characteristics:

[0139] Thickness: 0.8mm; Weight: 460g...

Embodiment 3

[0144] Embodiment 3: Animal manure nano-film aerobic composting device of the present invention

[0145] The implementation of this embodiment is the same as Example 1, except that the anti-seepage layer (3) is a concrete layer with a thickness of 18cm that is laid with an anti-seepage membrane made of high-density polyethylene material; The anti-seepage layer (3) is higher than the end away from the main engine (1), and the angle between the bottom surface of the anti-seepage layer (3) and the ground is 5°; the upward pipe wall of the air supply pipe (2) is lower than the anti-seepage layer (3) The upper surface is 1.5mm; the air supply pipe grooves (2-1) of the anti-seepage layer (3) are 8 concentric elliptical pipe grooves; 9 detectors with sealing covers or sealing plugs are set on the composite nano-membrane (4) hole (4-1);

[0146] Composite nano film (4) has the following characteristics:

[0147] Thickness: 0.90mm; Weight: 470g / m 2 ;

[0148] Tensile strength: 28MP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com