Composite nanofiltration film and preparation method thereof

A technology of composite nanofiltration membrane and ultrafiltration base membrane, which is applied in the field of composite nanofiltration membrane and its preparation, and can solve the problems of polyamide composite nanofiltration membranes such as hydrophilicity and low absolute value of volume charge density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

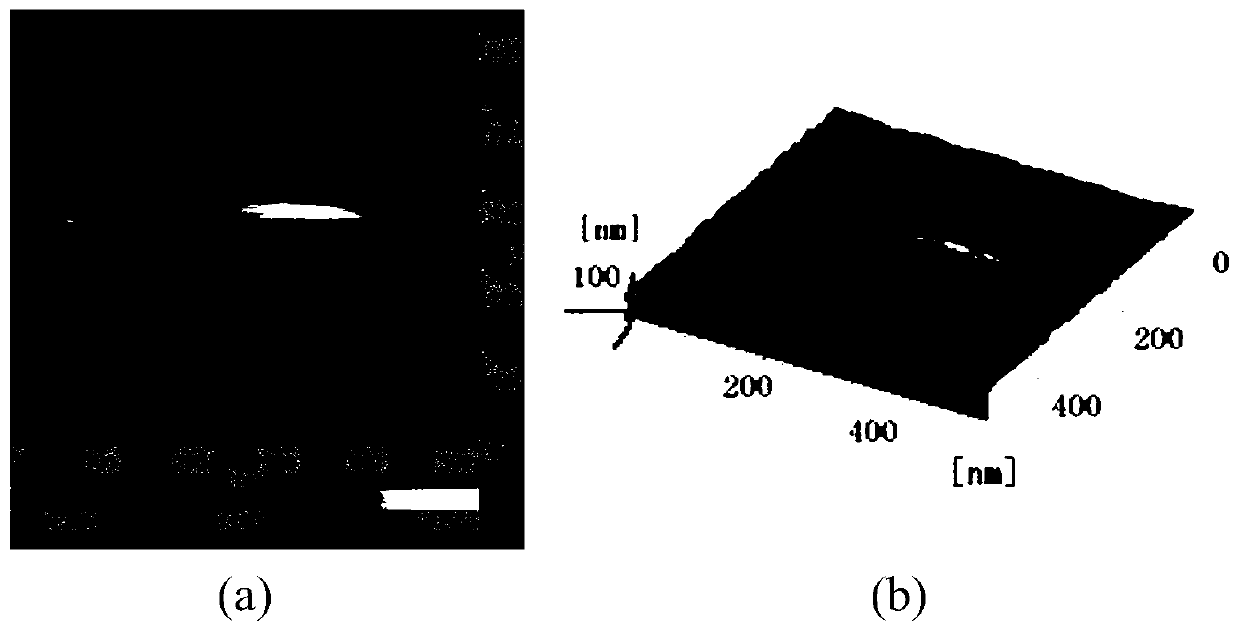

Image

Examples

preparation example Construction

[0064] The preparation method of the ultrafiltration base membrane is not particularly limited. For example, the ultrafiltration base membrane can be prepared by uni / biaxial stretching, non-solvent-induced gel phase inversion (NIPs) or thermally induced phase separation (TIPs).

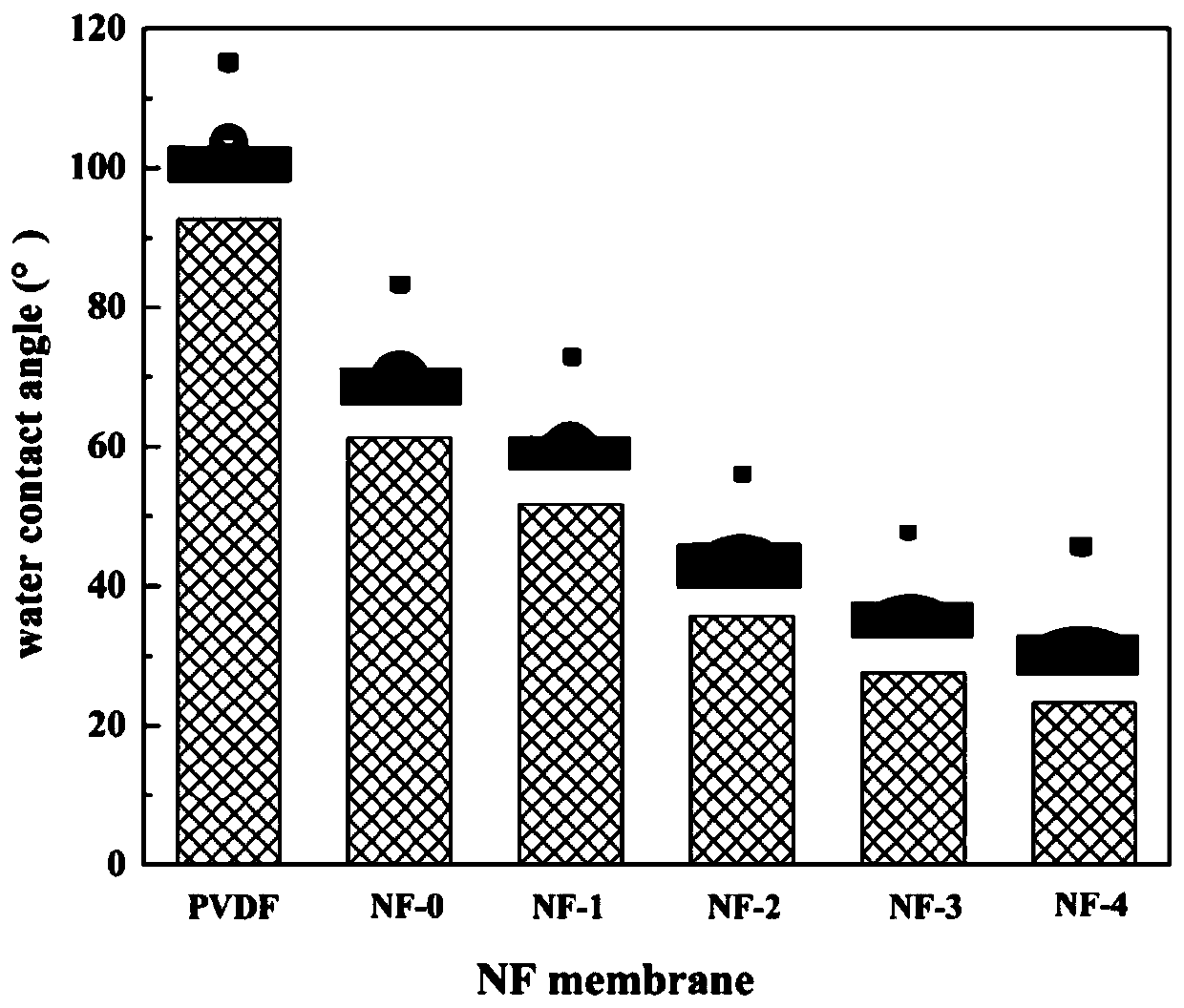

[0065] The surface active layer of the composite nanofiltration membrane of the invention comprises the reaction product of chitosan quaternary ammonium salt, beta-cyclodextrin and cross-linking agent. In the present invention, the substances contained in the surface active layer are mainly or all the reaction products of chitosan quaternary ammonium salt, β-cyclodextrin and cross-linking agent. The mass of the reaction product of chitosan quaternary ammonium salt, β-cyclodextrin and crosslinking agent usually accounts for more than 90wt% of the total mass of the surface active layer, such as more than 95wt%, more than 99wt% or 100wt%. In the surface active layer of the composite nanofiltration membra...

Embodiment 1

[0114] This embodiment prepares a positively charged composite nanofiltration membrane of chitosan quaternary ammonium salt / β-cyclodextrin, comprising the following steps:

[0115] (1) Preparation of chitosan quaternary ammonium salt: using chitosan (CS) and dimethyl diallyl ammonium chloride (DMDAAC) as raw materials, ammonium persulfate as initiator, synthesize dimethyl diallyl Chitosan quaternary ammonium salt grafted with ammonium chloride;

[0116] (2) Add 0.3w / v% PVA (M w : 2,500Da) aqueous solution is coated on molecular weight cut-off (MWCO) and be 30,000Da on the polysulfone ultrafiltration base membrane, to form an intermediate layer between active layer and ultrafiltration membrane, dry in the air;

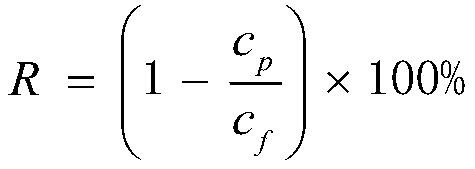

[0117] (3) 0.8 g of the chitosan quaternary ammonium salt prepared in step (1) and 0.2 g of β-cyclodextrin were dissolved in 100 ml of deionized water to obtain an aqueous phase solution. Soak the polysulfone ultrafiltration base membrane treated in step (2) in the aq...

Embodiment 2

[0128] This embodiment prepares a positively charged composite nanofiltration membrane of chitosan quaternary ammonium salt / β-cyclodextrin, comprising the following steps:

[0129] (1) adopt the method in embodiment 1 to make the chitosan quaternary ammonium salt of dimethyl diallyl ammonium chloride graft;

[0130] (2) Add 0.2w / v% PVA (M w 2500Da) aqueous solution is coated on the polyacrylonitrile ultrafiltration base membrane (MWCO is 20,000Da) to form an intermediate layer between the active layer and the ultrafiltration membrane, and dry;

[0131] (3) Chitosan quaternary ammonium salt, 0.3g beta-cyclodextrin, 0.01g lithium chloride and 0.02g sodium dodecylsulfonate prepared by 1.0g step (1) were dissolved in 100ml deionized water to obtain Aqueous phase solution; after the polyacrylonitrile (PAN) ultrafiltration base membrane processed through step (2) is soaked in the aqueous phase solution for 5min, remove the excess aqueous phase solution on the surface of the ultrafilt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mwco | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com