Method for testing and evaluating capacity of corrosion prevention system of cosmetic

A capability testing and cosmetic technology, applied in the field of capability testing and evaluation of cosmetic anti-corrosion systems, can solve the problems of prolonging production cycle, increasing production cost, complicated operation, etc., and achieving the effect of accurate judgment, strong reliability and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Preparation of preparation media and reagents:

[0036] 1. Physiological saline:

[0037] Ingredients: Sodium Chloride 8.5g;

[0038] Add distilled water to 1000ml; after dissolving, dispense into Erlenmeyer flasks with glass beads, 90ml per bottle, and autoclave at 121°C (15lb) for 20min.

[0039] 2. Lecithin-Tween 80-nutrient agar medium;

[0040] 2.1. Ingredients: 20g of protein;

[0041] Beef extract 3g;

[0043] Agar 15g;

[0044] Lecithin 1g;

[0045] Tween 80 7g;

[0046] Distilled water 1000ml.

[0047] 2.2. Preparation method: first add lecithin to a small amount of distilled water, heat to dissolve, add Tween-80, add other ingredients (except agar) to the rest of distilled water, dissolve, add dissolved lecithin, Tween 80, mix well, adjust the pH to 7.1-7.4, add agar, autoclave at 121°C (15lb) for 20min, and store in a cool and dark place for later use.

[...

example

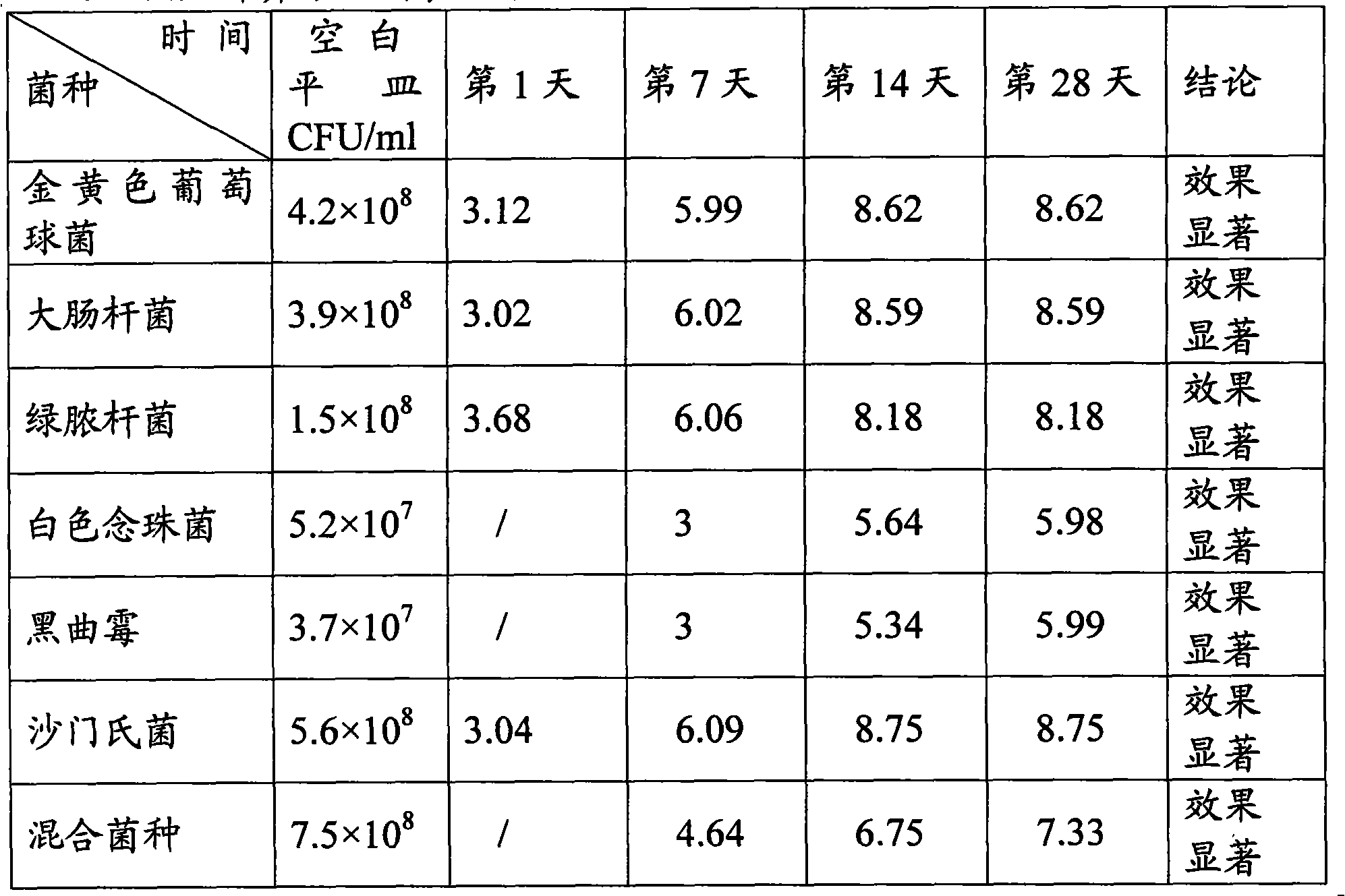

[0070] Microbial challenge test of a certain whitening skin care lotion with antiseptic system compounded with methylparaben, propylparaben and honeysuckle extract:

[0071] 1. Take a sample of 315ml, and add 45ml each to seven 100ml Erlenmeyer flasks evenly for use; take 7 glass test tubes each containing 10ml sterilized saline for use, and 42 glass test tubes each containing 9ml saline Test tube spare.

[0072] 2. Take 6 kinds of pure strains (the 3rd to 7th generation activated), scrape one ring of each pure strain, add them to 6 glass test tubes, vibrate to make a uniform pure strain solution, and then Scrape one ring of the pure strains and add them to the remaining 1 glass test tube to prepare a uniform mixed strain solution for future use. The storage time of the whole process should not exceed 3 hours.

[0073] 3. Take 5ml each from the glass test tubes that have been prepared into a uniform strain solution, add them to a spare conical flask with 45ml of sample soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com