ZnO-containing chitosan/sodium alginate antibacterial cling film and preparation method thereof

A sodium alginate film and sodium alginate technology are applied in the field of fresh food packaging materials, can solve the problems of poor water resistance and poor water vapor barrier performance of brittle sodium alginate film, and achieve simple methods, high antibacterial performance, Effects of low water solubility and water vapor transmission coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

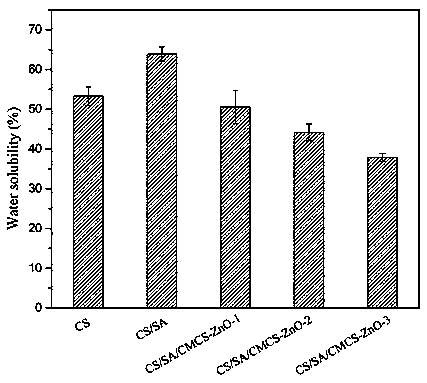

[0034] Example 1 (SA / SH-ZnO-1)

[0035] The present embodiment provides a kind of preparation method of chitosan / sodium alginate antibacterial preservative film containing ZnO, comprises the following steps: first prepare starch-ZnO nanoparticle in situ, then prepare chitosan film liquid, and prepare Add ZnO evenly to sodium alginate solution to prepare sodium alginate film solution, cast chitosan film solution on glass plate, dry, then cover sodium alginate film solution on top, cast film, dry, and finally Add chitosan film solution, cast into film. Specific steps are as follows:

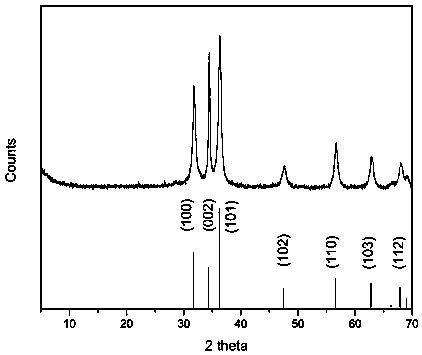

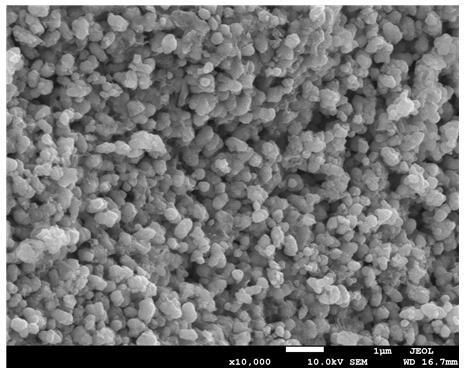

[0036] Dissolve 1g of soluble starch in 100ml of deionized water, raise the temperature to 90°C in a magnetic stirrer and stir for 30min until completely dissolved; 0.595g of Zn(NO 3 ) 2 ·6H 2 O was added to the above solution and stirred for 30 minutes; then 50ml of 0.2M NaOH solution was added dropwise, stirred for 2 hours, centrifuged, washed, and dried in an oven at 50°C for 24 hours to obt...

Embodiment 2

[0039] Example 2 (CS / SA / SH-ZnO-2)

[0040] The present embodiment provides a kind of preparation method of chitosan / sodium alginate antibacterial preservative film containing ZnO, and concrete steps are as follows:

[0041] Dissolve 0.5g soluble starch in 100ml deionized water, heat up to 90°C in a magnetic stirrer and stir for 30min until completely dissolved; 0.595g Zn(NO 3 ) 2 ·6H 2 O was added to the above solution and stirred for 30 minutes; then 50ml of 0.3M NaOH solution was added dropwise, stirred for 2 hours, centrifuged, washed, and dried in an oven at 70°C for 24 hours;

[0042] Dissolve 1 mL of glacial acetic acid in 100 mL of deionized water, add 2 g of chitosan and 0.5 g of glycerin, and stir for 1 h until uniform to obtain a chitosan film solution. Add 0.05g of the zinc oxide nanoparticles prepared above into 100ml of deionized water, ultrasonic the probe, the ultrasonic power of the probe is 300W, ultrasonic 3s, intermittent 2s, stir evenly, then add 2g sodi...

Embodiment 3

[0043] Embodiment 3 (CS / SA / SH-ZnO-3)

[0044] The present embodiment provides a kind of preparation method of chitosan / sodium alginate antibacterial preservative film containing ZnO, and concrete steps are as follows:

[0045] Dissolve 2g of soluble starch in 100ml of deionized water, heat up to 90°C in a magnetic stirrer and stir for 30min until completely dissolved; 0.595g of Zn(NO 3 ) 2 ·6H 2 O was added to the above solution and stirred for 30 minutes; then 50ml of 0.1M NaOH solution was added dropwise, stirred for 2 hours, centrifuged, washed, and dried in an oven at 80°C for 24 hours;

[0046] Dissolve 1 mL of glacial acetic acid in 100 mL of deionized water, add 2 g of chitosan and 2 g of glycerin, and stir for 1 h until uniform to obtain a chitosan film solution. Add 0.1g of zinc oxide nanoparticles prepared above into 100ml of deionized water, ultrasonic probe, ultrasonic power of the probe is 400W, ultrasonic 4s, intermittent 1s, stir well, then add 2g sodium algi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com