A cleaning method for a reverse osmosis system

A technology of reverse osmosis and reverse osmosis membrane, applied in reverse osmosis, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc., can solve problems such as cleaning schemes not mentioned, and achieve the effect of reducing salt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

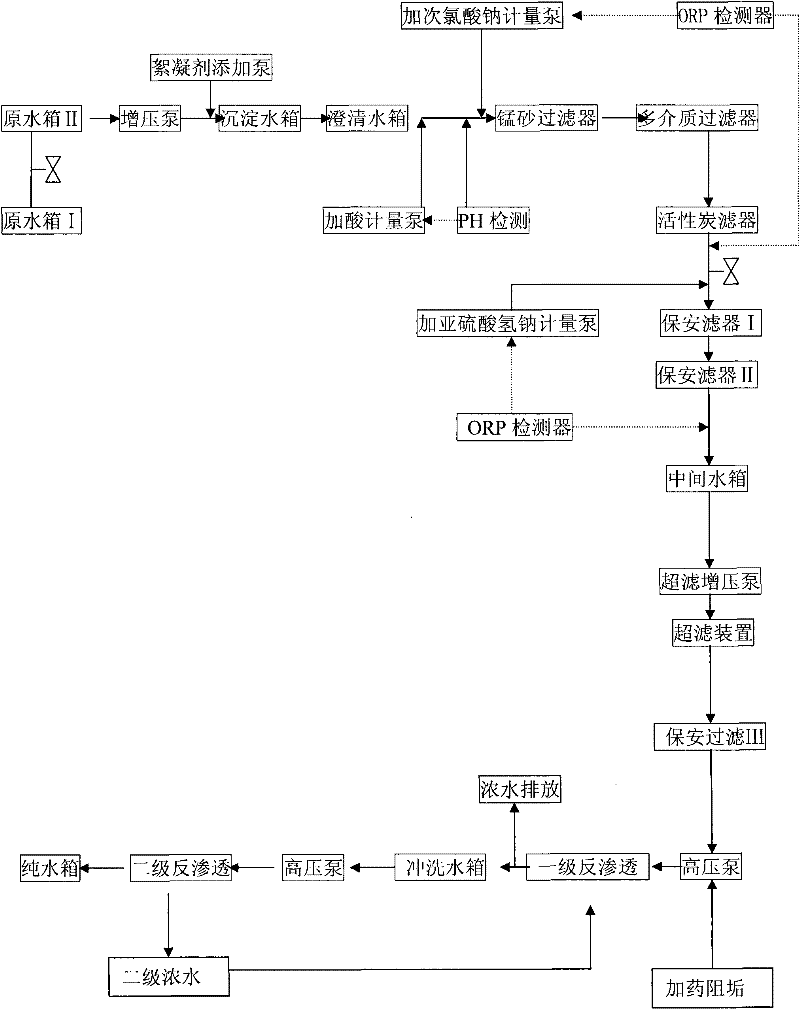

Method used

Image

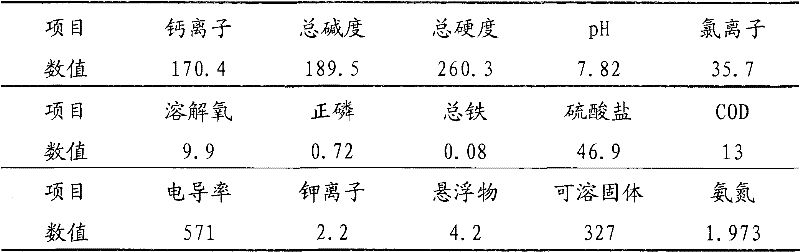

Examples

Embodiment 1

[0042] Weigh 1Kg of disodium ethylenediaminetetraacetic acid (disodium EDTA), 1Kg of sodium N-oleoyl-N-methyl taurate, acrylic acid / hydroxypropyl acrylate / 2-acrylamide-2-methylpropylsulfonate Acid terpolymer 3.5g, add 70Kg deionized water, stir to make it fully dissolve, add deionized water to solution weight is 100Kg, promptly obtain the 100Kg reverse osmosis cleaning solution of required preparation, use NaOH to make the cleaning solution The pH was adjusted to 11.0.

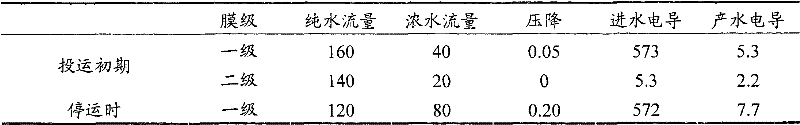

[0043] The reverse osmosis membrane is cleaned with the cleaning solution of Example 1, and the specific cleaning process is as follows:

[0044] 1) Adjust the primary membrane pressure of the reverse osmosis system to 0.4MPa, adjust the primary concentrated water output of the reverse osmosis system to 160L / h, and the primary reverse osmosis water output to 40L / h, and close the secondary reverse osmosis membrane. Rinse the reverse osmosis primary membrane system with reverse osmosis product water for 12 minu...

Embodiment 2

[0056] Weigh 2.5Kg of disodium ethylenediaminetetraacetic acid (disodium EDTA), 2.5Kg of sodium N-oleoyl-N-methyl taurate, acrylic acid / hydroxypropyl acrylate / 2-acrylamide-2-methylpropane The terpolymer 6g of base sulfonic acid, add 70Kg deionized water, stir and make it fully dissolve, add deionized water to the solution weight is 100Kg, promptly obtain the 100Kg reverse osmosis cleaning solution of required preparation, use NaOH to make cleaning solution The pH value was adjusted to 11.2.

[0057] The reverse osmosis membrane is cleaned with the cleaning solution of Example 2, and the specific cleaning process is the same as that of Example 1.

Embodiment 3

[0059] Weigh 0.5Kg of disodium ethylenediaminetetraacetic acid (disodium EDTA), 0.5Kg of sodium N-oleoyl-N-methyl taurate, acrylic acid / hydroxypropyl acrylate / 2-acrylamide-2-methylpropane Add 2 g of terpolymers of methyl sulfonic acid, add 70Kg deionized water, stir to make it fully dissolve, add deionized water until the solution weight is 100Kg, and obtain the 100Kg reverse osmosis cleaning solution that needs to be prepared, and use NaOH to make the cleaning solution The pH value was adjusted to 11.4.

[0060] The reverse osmosis membrane is cleaned with the cleaning solution of Example 3, and the specific cleaning process is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com