Improved method for controlling polymerized emulsion microbial pollution by using carbon dioxide detection

A technology of carbon dioxide and polymerized emulsion, which is applied in the direction of biochemical equipment and methods, measurement/inspection of microorganisms, analysis using chemical indicators, etc., can solve problems such as product loss, and achieve the effect of minimizing sampling errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Control

[0029] Sterilized with AIRFLEX 400 (1600g) polyvinyl alcohol-stabilized vinyl acetate / ethylene polymer emulsion is placed in a 2L plastic Nalgene container, and two holes are made on the plastic lid of the container, one of which is used to insert a carbon dioxide sensor, and the other is a small diameter Many holes are opened, so that the inside of the container is communicated with the atmosphere and keeps the pressure constant. A Vaisala GMT222 direct read CO2 converter connected to the data logger and computer was used as the measurement device. The cap was then tightened and the headspace carbon dioxide concentration was measured for 3 days. The headspace carbon dioxide concentration was stable at about 400 ppm throughout the monitoring period.

[0030] No microbial growth was observed during the control process when the polymeric emulsion was streaked.

Embodiment 2

[0031] Embodiment 2: the mensuration of carbon dioxide in polluted emulsion

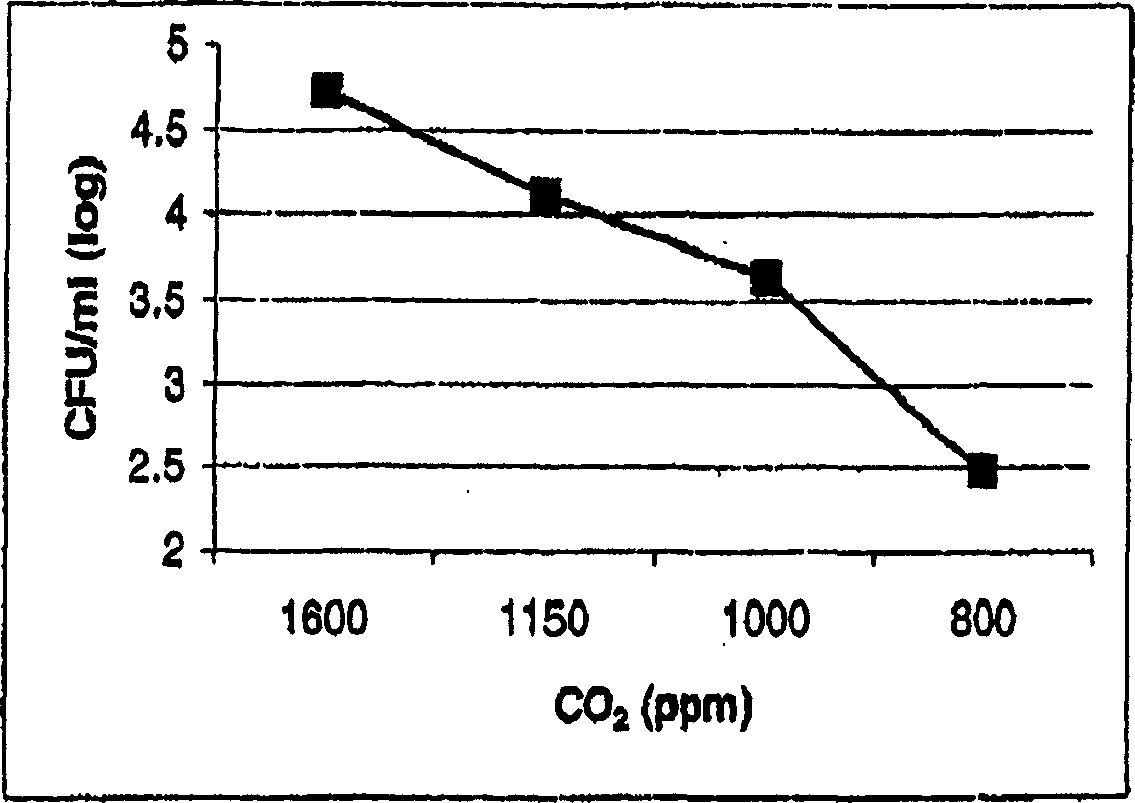

[0032] To determine the efficacy of carbon dioxide measurement as a detection mechanism for microbial growth, the AIRFLEX 400 (1600 g) of polyvinyl alcohol-stabilized (with some antimicrobial agent) vinyl acetate / ethylene polymer emulsions were inoculated with gluconoacetic acid bacteria liquefaction. The concentration of liquefied gluconoacetic acid bacteria in Airflex400 emulsion was determined in potato dextrose agar by dilution plate metering method, and the result was 5.4×10 4 cfu / ml. The polluted emulsion was placed in a 2L plastic Nalgene container, and the lid was treated the same as in Example 1, with a carbon dioxide sensor hole and a vent hole, and tightened with screws. Within minutes, the amount of carbon dioxide in the headspace of the vessel began to rise above the initial value (-400 ppm). After 2 days of continuous monitoring of the sample, the carbon dioxide concentration in th...

Embodiment 3

[0033] Example 3: Measurement of Carbon Dioxide After Addition of Antimicrobial Agent

[0034] To the same contaminated sample as described in Example 2, 400 ppm of dodecylguanidine hydrochloride (DGH) antimicrobial agent was added to reduce the concentration of Gluconoacetic acid bacteria liquefied.

[0035] The concentration of carbon dioxide in the headspace of the vessel was monitored in the same manner as in Examples 1 and 2. After 2 days of continuous monitoring of the sample, the carbon dioxide concentration in the headspace dropped to around 1150 ppm. The sample of vinyl acetate / ethylene polymer emulsion stabilized with AIRFLEX400 polyvinyl alcohol was taken out from the container, and the concentration of liquefied gluconoacetic acid bacteria in potato dextrose agar was determined by dilution plate method, and the liquefied gluconoacetic acid in AIRFLEX400 emulsion was found Bacillus contamination concentration is 1.3×10 4 cfu / ml.

[0036] This example shows that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com