MOF-modified antipollution composite reverse osmosis membrane and preparation method thereof

A reverse osmosis membrane, anti-pollution technology, used in reverse osmosis, water pollutants, semi-permeable membrane separation, etc. The effect of enhancing and reducing penetration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

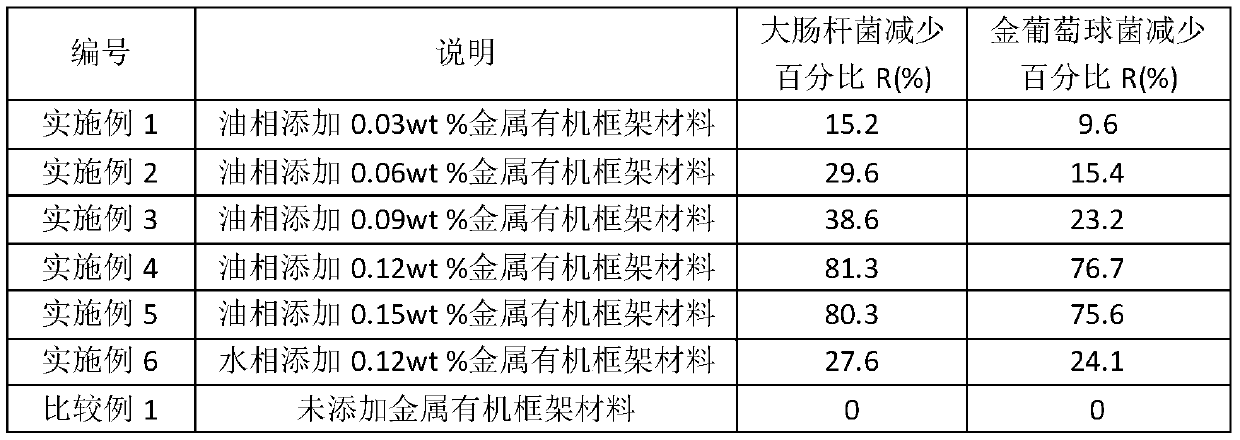

Embodiment 1

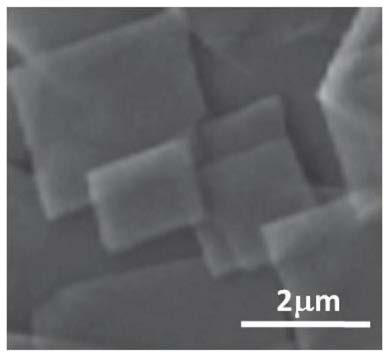

[0032] (1) Preparation of copper-1,4-benzenedicarboxylate metal-organic framework materials

[0033] Dimethylformamide and acetonitrile were mixed at room temperature at a volume ratio of 2:1 as the first mixed solvent, and 1,4-benzenedicarboxylic acid was dissolved in the first mixed solvent at a concentration of 10 mg / mL, and stirred at room temperature for 30 minutes to obtain a homogeneous 1,4-benzenedicarboxylic acid solution.

[0034] Mix dimethylformamide and acetonitrile at room temperature in a volume ratio of 1:1 as the second mixed solvent; mix dimethylformamide and acetonitrile at room temperature in a volume ratio of 1:2 as the third mixed solvent. Copper nitrate trihydrate Cu(NO 3 ) 2 ·3H 2 O was dissolved in the third mixed solvent at a concentration of 10 mg / mL, and stirred at room temperature for 30 minutes to obtain a uniform copper nitrate solution. Slowly add 1,4-benzenedicarboxylic acid solution, the second mixed solvent, and copper nitrate solution in...

Embodiment 2

[0041] Compared with Example 1, the only difference is that the mass fraction of copper-1,4-benzenedicarboxylate metal organic framework material in n-hexane mixed solution is replaced by 0.06wt%, and the others are the same as Example 1.

Embodiment 3

[0043] Compared with Example 1, the only difference is that the mass fraction of copper-1,4-benzenedicarboxylate metal organic framework material in n-hexane mixed solution is replaced by 0.09wt%, and the others are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com