Biochar slow release base fertilizer special for wheat and preparation method thereof

A technology of biochar and wheat, applied in application, fertilization device, fertilizer mixture, etc., can solve problems such as difficulty in increasing fertilizer production, failure to continuously increase grain production, and aggravate fertilizer waste and loss, so as to save planting costs and ensure sustainable Sustained development and the effect of reducing the amount of fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

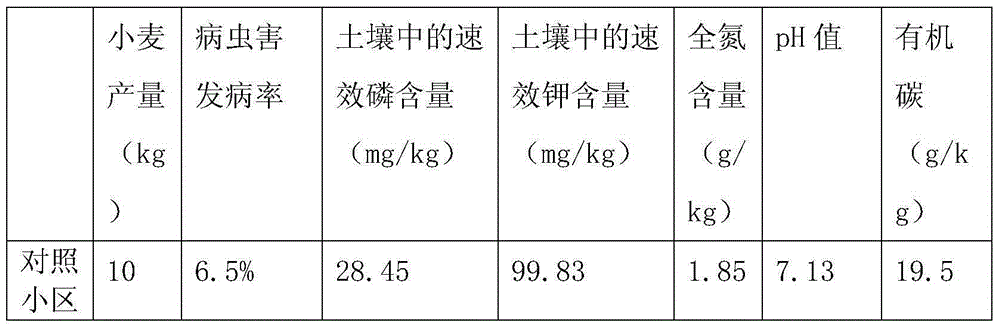

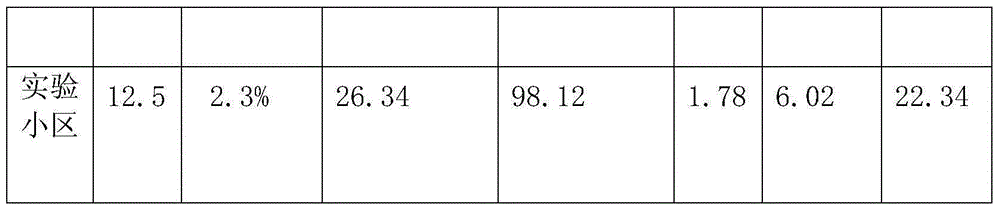

Examples

Embodiment Construction

[0022] A special base fertilizer for biochar slow-release wheat, comprising a core layer and a coating layer coated on the surface of the core layer, wherein the core layer is formed by mixing the following components by weight (kg): biochar 35, urea 13, Potassium dihydrogen phosphate 33, potassium chloride 18, weathered coal 35, botanical fungicide 0.4, abamectin dregs 4, vermiculite powder 6, fertilizer additive 0.4, the weight of the core layer is 55% of the total weight of the slow-release fertilizer , the coating layer is a mixture of biochar powder and modified attapulgite, and the weight of the coating layer is 45% of the total weight of the slow-release fertilizer;

[0023] Among them, the preparation method of modified attapulgite: calcining attapulgite at 250°C for 2-3 hours, taking it out and soaking it in dilute sulfuric acid with 45% of attapulgite weight for 35 minutes, adding attapulgite weight 9 % glutinous rice flour, 4% konjac gum, 13% polyvinyl alcohol, 0.4%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com