Electro-deionization method and electro-deionization device for recycling ammonia nitrogen waste water

A technology for electrodeionization and ammonia nitrogen wastewater, applied in separation methods, dispersed particle separation, ammonium salt preparation, etc., can solve the problems of low recovery rate of reverse osmosis treated water, increase the cost of wastewater treatment, increase operating costs, etc., and achieve clean The effect of civilized production, improvement of production and labor environment, and reduction of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

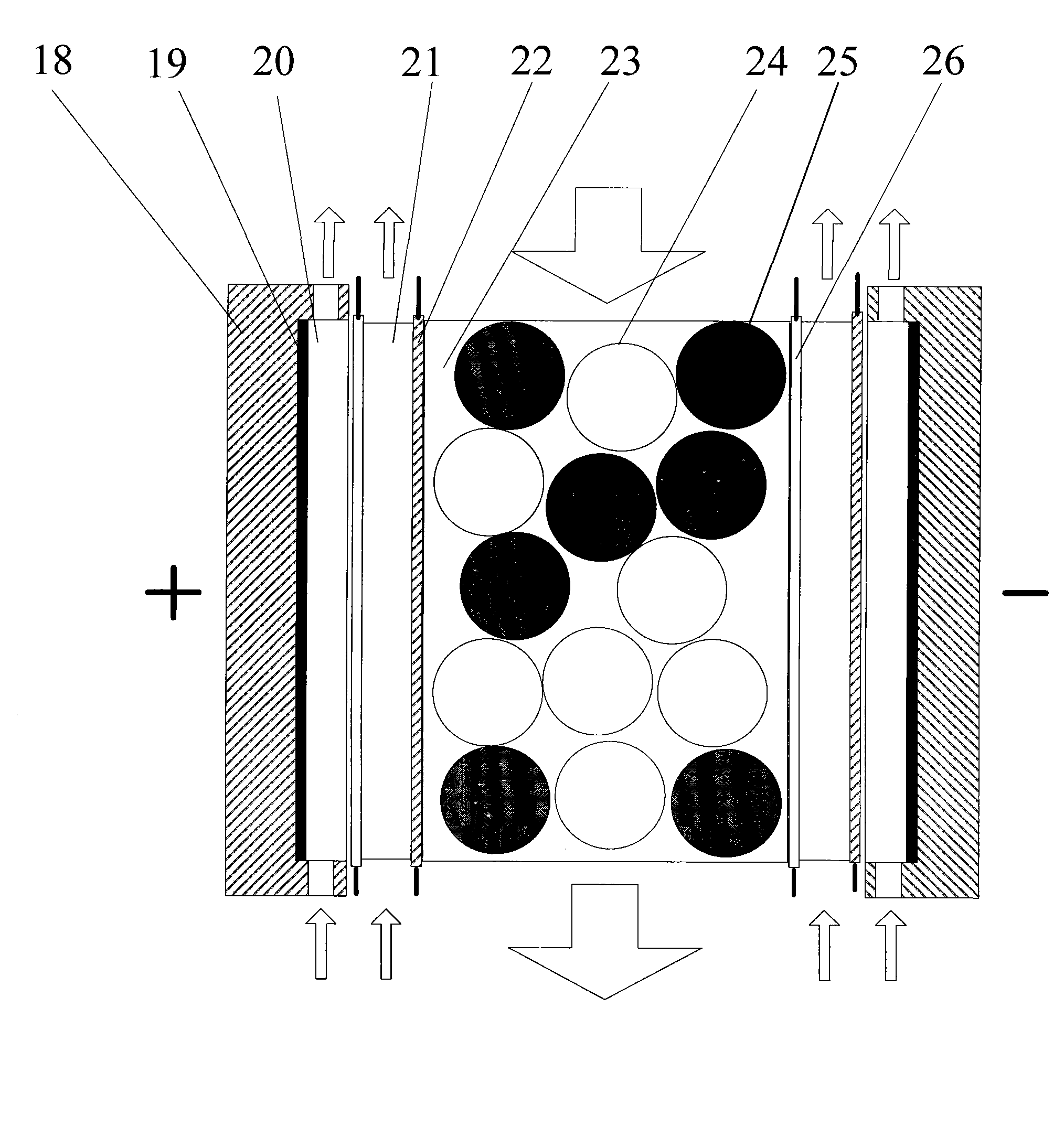

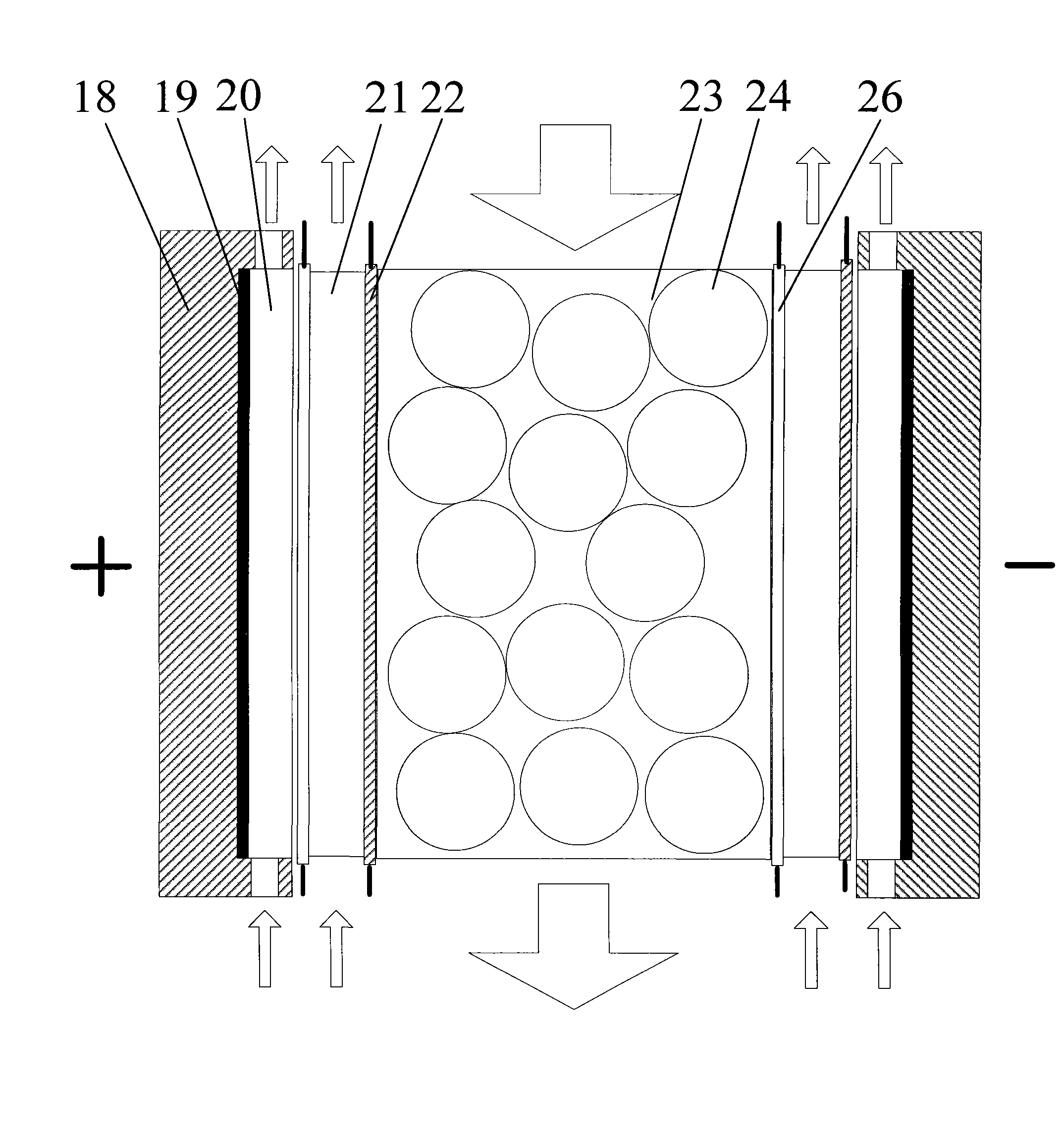

[0022] The principle, device structure and examples will be explained in detail below in conjunction with the accompanying drawings.

[0023] Taking ammonium nitrate wastewater from a factory as an example, the mass concentration of ammonium nitrate in the water is 0.25%. The waste water is the condensate in the production process of ammonium nitrate. The water quality is pure. Except for a certain amount of ammonium nitrate, it does not contain other salts. It can be treated by simple pretreatment methods to make the effluent water quality reach the pollution coefficient SD I≤5. Turbidity≤1NTU, COD≤1mg / L, hardness≤1mg / L.

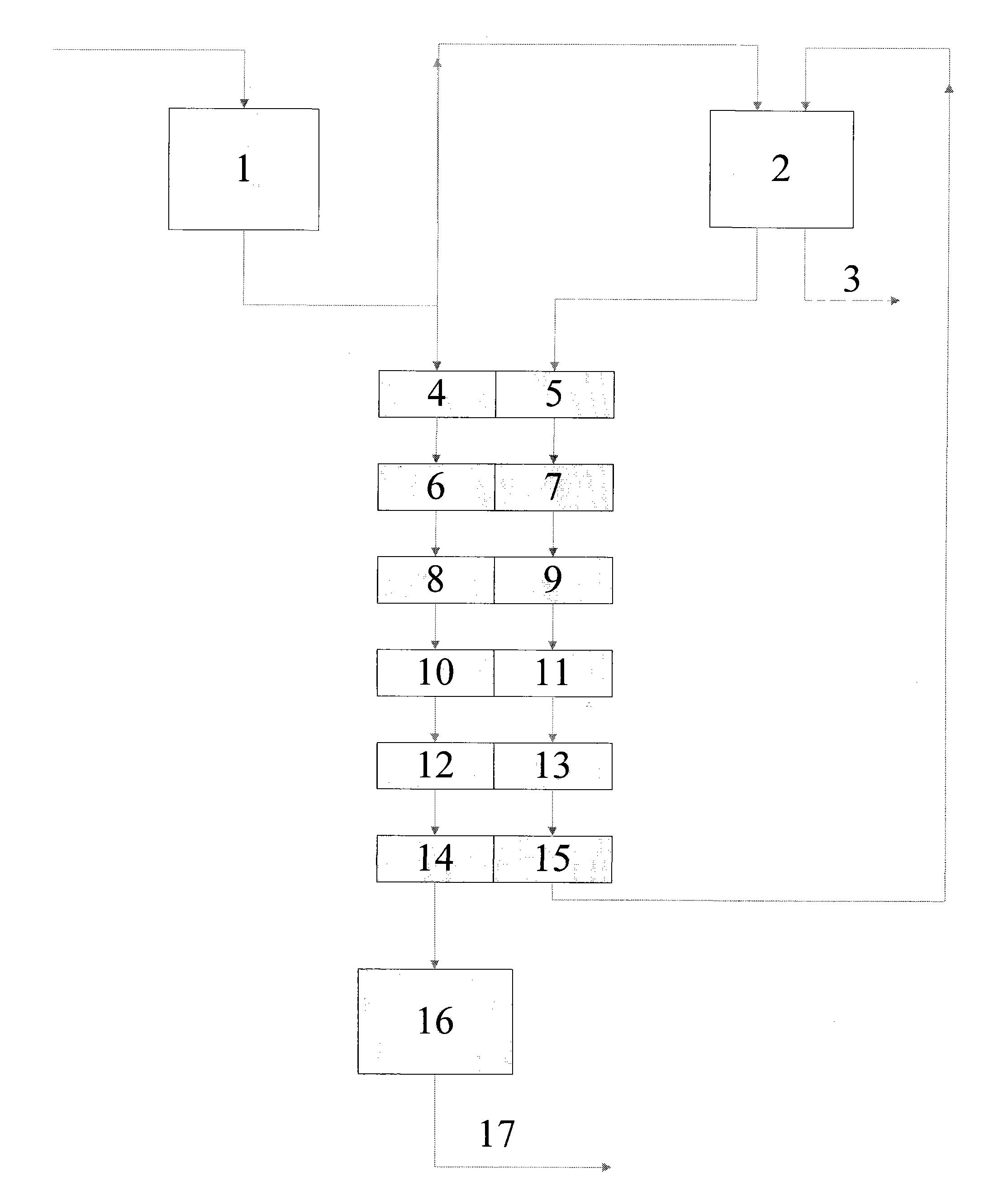

[0024] This embodiment adopts electrodeionization treatment, and divides the 0.25% ammonia nitrogen wastewater that has been pretreated and meets the above requirements into two streams, one stream is sent to the electrodeionization device for treatment, and the water stream passes through each serial module arranged in parallel. The number of modules conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com