Method for treatment of salt-containing wastewater by forward osmosis membrane distillation

A forward osmosis membrane, salt-containing wastewater technology, applied in water/sewage treatment, chemical instruments and methods, textile industry wastewater treatment, etc. The effect of low cost and reduced water quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

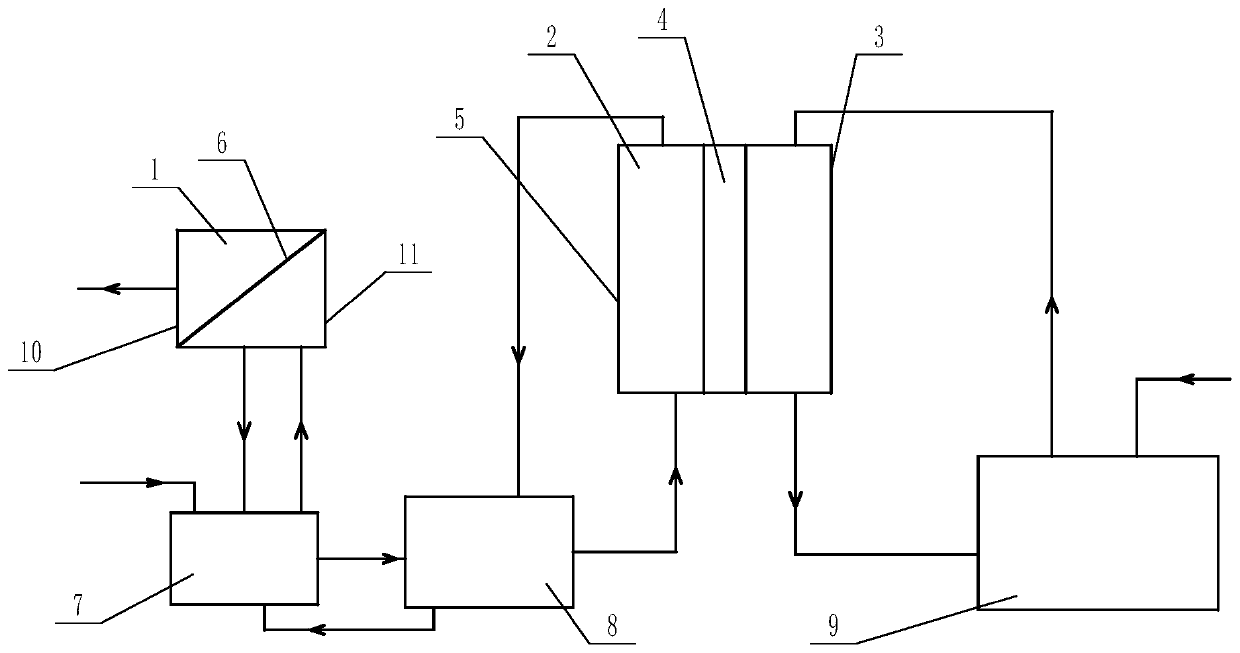

Method used

Image

Examples

Embodiment 1

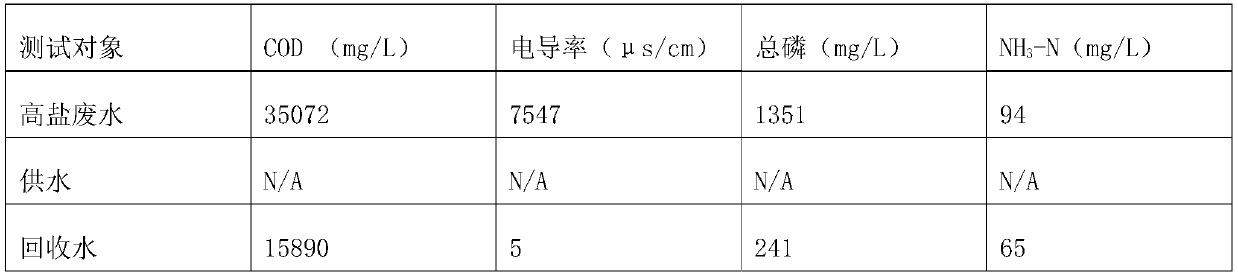

[0048] 1. Characteristics of high-salt wastewater

[0049] This technical solution concentrates salt substances and recycles high-salt wastewater. In this embodiment, the high-salt wastewater is formed after conventional treatment such as removing suspended solids. The characteristic parameters of water quality are as follows: pH 8, COD 35072mg / L, Conductivity 7547μs / cm, total phosphorus 1351mg / L, NH 3 -N 94mg / L. The salt substance in the high-salt wastewater is mainly sodium chloride, and the content of the salt substance is 3.4w.t%.

[0050] Among them, COD is the abbreviation of Chemical Oxygen Demand, which refers to chemical oxygen demand, which refers to the amount of oxidant consumed when treating water samples with strong oxidants. It is an index indicating the amount of reducing substances in water. The reducing substances in water mainly refer to organic matter. COD is an indicator to measure the content of organic matter in water, NH 3 -N is the ammonia nitrogen...

Embodiment 2

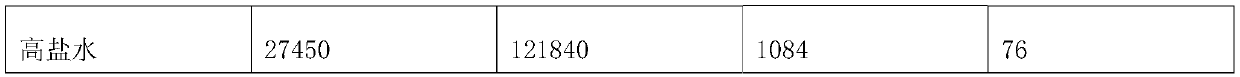

[0067] The present embodiment is basically the same as Example 2, the difference is: the water quality characteristic parameters of high-salt wastewater, the characteristic parameters are as follows: pH 7.5, COD 27891mg / L, conductivity 5147μs / cm, total phosphorus 587mg / L, NH 3 -N 156mg / L. The salt substance in the high-salt wastewater is mainly sodium sulfate, and the content of the salt substance is 3.0w.t%. The characteristic parameters of the final product and the intermediate product are compared as shown in Table 2. In this example, the water recovery rate was 94.56%.

[0068] Table 2:

[0069] testing object COD (mg / L) Conductivity (μs / cm) Total phosphorus (mg / L) NH 3 -N (mg / L)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com