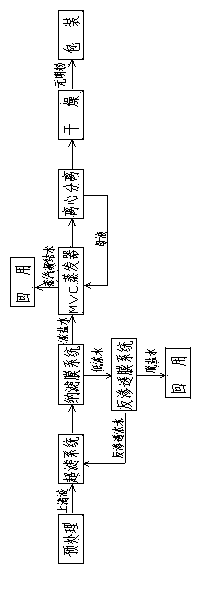

White carbon black production wastewater treatment technology

A technology for production of wastewater and treatment process, which is applied in the fields of neutralization water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

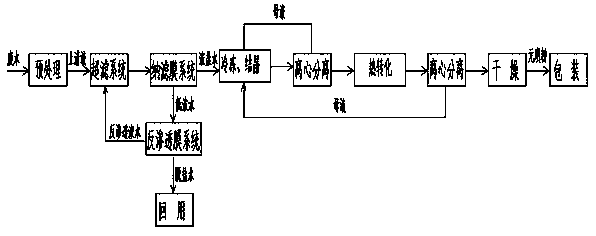

Image

Examples

Embodiment Construction

[0015] 1m waste water from the white carbon black production workshop 3 , wherein the mass content of sodium sulfate is about 3%, and the pH is 4 to 6. When stirring, add sodium hydroxide with a mass percentage of 32%, adjust the pH value of the wastewater to 6 to 8, and then polymerize Aluminum chloride and wastewater are added at a ratio of 0.03 to 0.07:1000, and polyacrylamide and wastewater are added at a ratio of 0.2 to 1.2:10 6 Proportionally added. After 10 minutes of flocculation and sedimentation, the supernatant enters the ultrafiltration system to remove suspended solids and macromolecular colloids in the water. After ultrafiltration, the SDI value of the effluent is determined to be ≤3.

[0016] Pressurize the ultrafiltration effluent and subsequent reverse osmosis concentrated water to 40~45bar to enter the nanofiltration system, the nanofiltration low-concentration product water is 0.77t, the sodium sulfate content is ≤2000mg / L, the nanofiltration high-concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com