Processing method of salt containing water and salt containing processing system

A treatment method and concentrated water technology, which is applied in the brine treatment system and the brine treatment field, can solve the problems of operation complexity, increased equipment investment cost, operation and maintenance cost, and complicated process flow, so as to achieve simple process flow and reduce Investment cost and operation and maintenance cost, and the effect of simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

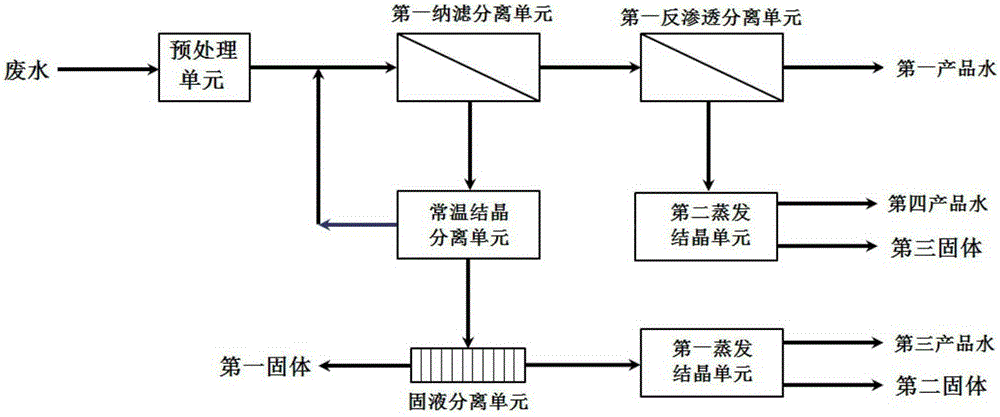

[0103] This embodiment adopts figure 1 The system shown treats a brine, in which a synthetic brine was used to simulate the pretreated wastewater, the composition of which is shown in Table 1.

[0104] Table 1

[0105] project

COD

Na +

Ca 2+

Cl -

SO 4 2-

TDS

Supersaturation (CaSO 4 )

unit

mg / L

mg / L

mg / L

mg / L

mg / L

mg / L

%

value

96.00

1311.12

488.51

2021.89

1170.08

4991.60

48.02

[0106] The first nanofiltration separation unit used in this embodiment is a first-stage one-stage nanofiltration system composed of 8 Dow NF90-400 nanofiltration membrane elements; the normal temperature crystallization separation unit is a total volume of 15m 3 The clarifier; the first reverse osmosis separation unit is a one-stage two-stage reverse osmosis system composed of 16 Dow BW30-400 reverse osmosis membrane elements. The influent flow of synthetic brine is 10.00m 3 / ...

Embodiment 2

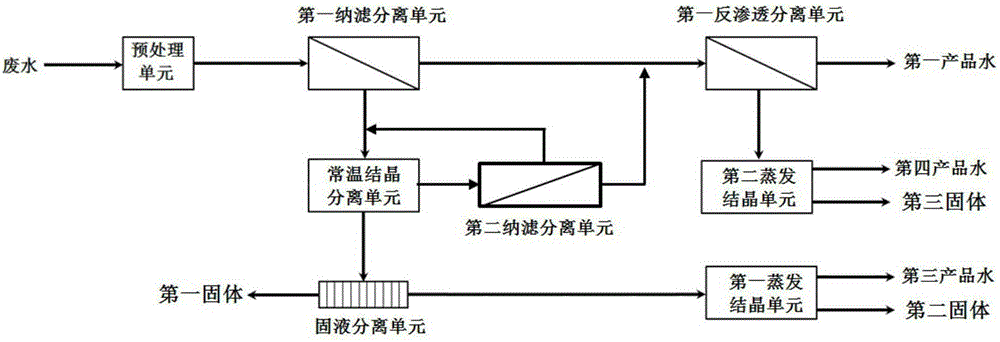

[0115] This embodiment adopts figure 2 The system shown treats a brine, wherein the pretreated wastewater is simulated with a synthetic brine, the composition of which is the same as that used in Example 1.

[0116] The first nanofiltration separation unit, the first reverse osmosis separation unit and the room temperature crystallization separation unit used in this example are the same as those in Example 1. The second nanofiltration separation unit used in this embodiment is the same as the first nanofiltration separation unit. The influent flow of synthetic brine is 10.00m 3 / h, the specific process is as follows.

[0117] (1) The flow rate is 10.00m 3 / h synthetic salt water, after adding 5.0mg / L scale inhibitor (active ingredient is organic phosphonate, Nalco Company, OSMOTREATOSM1035) to it, enter the first nanofiltration separation unit for nanofiltration separation, Among them, the inlet pressure of nanofiltration is 1.0MPa, and the flow rate is 6.80m 3 / h of th...

Embodiment 3

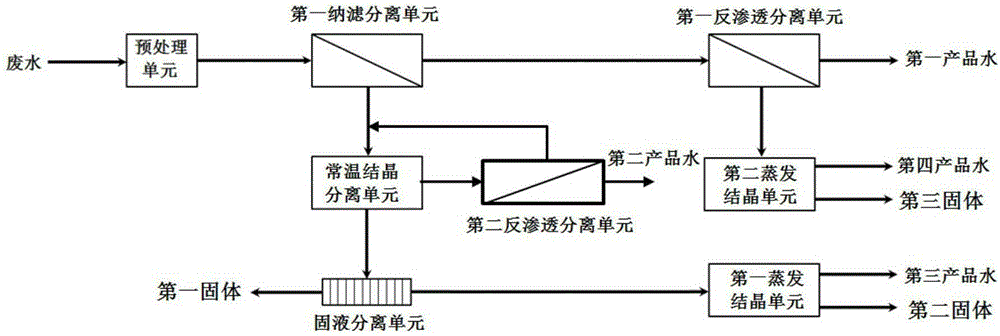

[0126] This embodiment adopts image 3 The system shown treats a brine, wherein the pretreated wastewater is simulated using a synthetic brine with the same composition as the synthetic water used in Example 1.

[0127] The first nanofiltration separation unit and normal temperature crystallization separation unit used in this example are the same as those in Example 1. The first reverse osmosis separation unit used in this example is a one-stage one-stage reverse osmosis system composed of eight Dow BW30-400 reverse osmosis membrane elements. The second reverse osmosis separation unit used in this example is a one-stage one-stage reverse osmosis system composed of six Dow SW30XLE-440i reverse osmosis membrane elements. The influent flow of synthetic brine is 10.00m 3 / h, the specific process flow of the present embodiment is as follows.

[0128] (1) The flow rate is 10.00m 3 / h synthetic salt water, after adding 5.0mg / L scale inhibitor (active ingredient is organic phosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com