Brown coal drying quality-increasing device and technique

A drying device, technology of lignite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

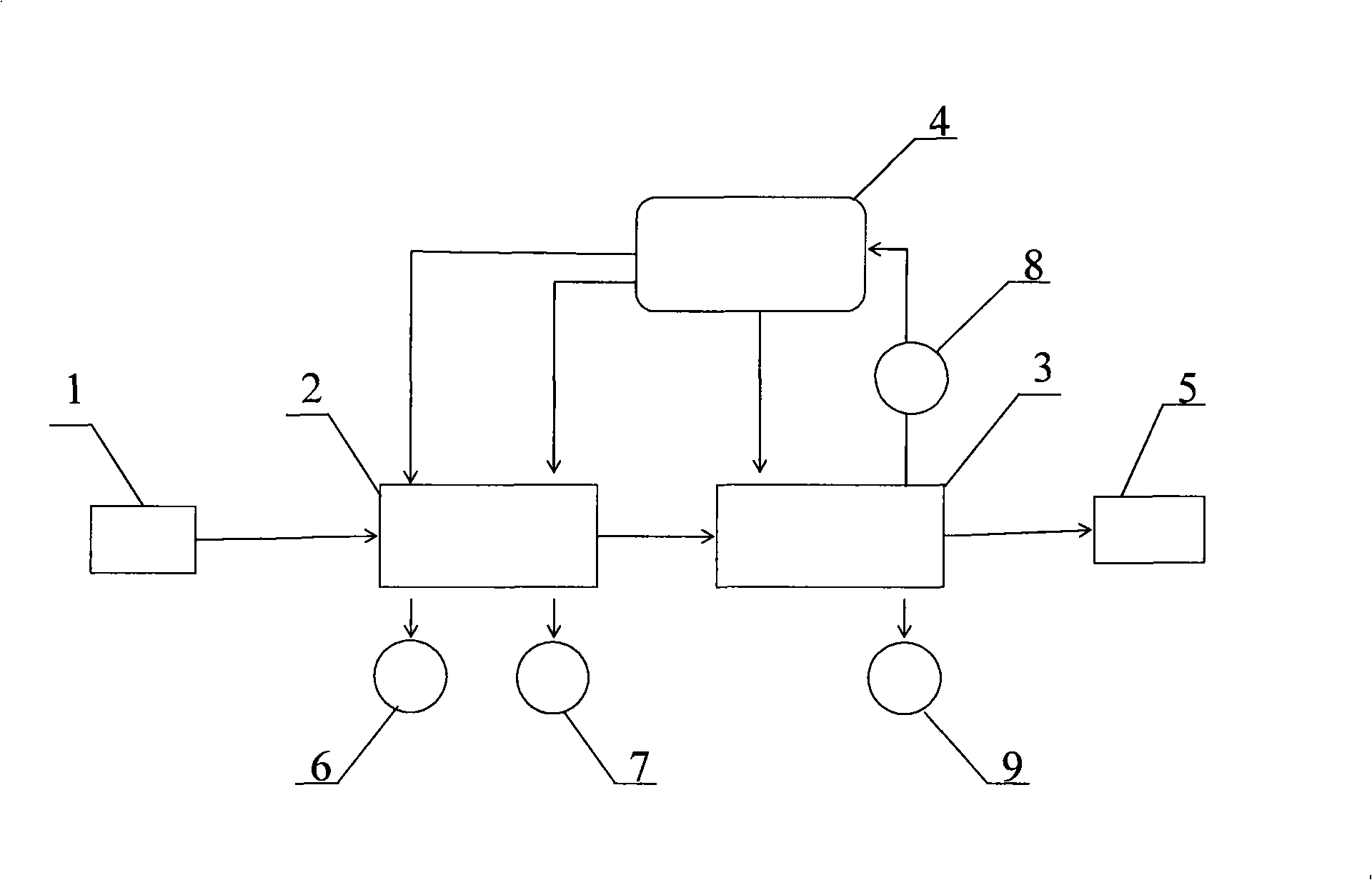

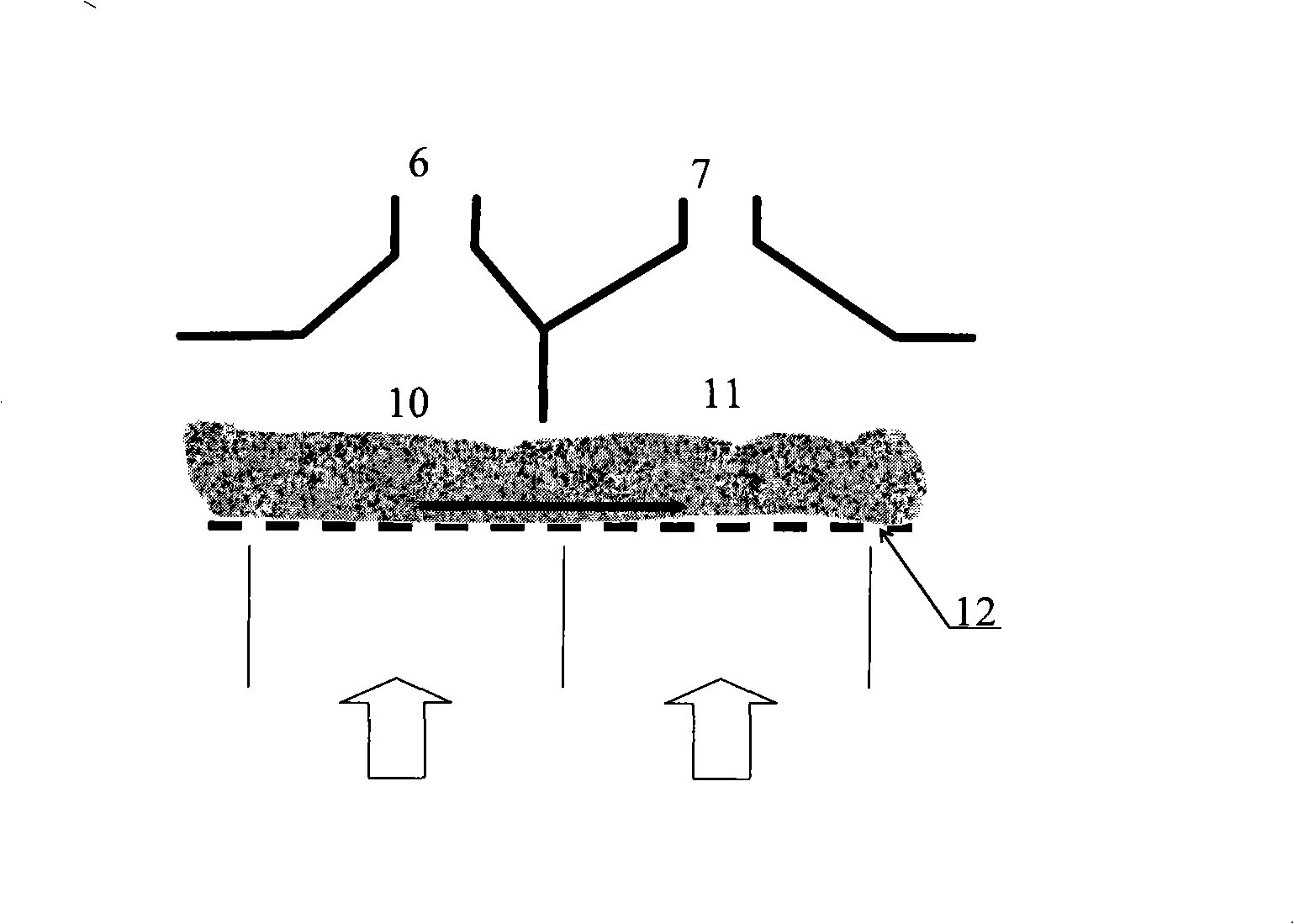

[0020] figure 1 It is a schematic diagram of the structure and process flow of the lignite drying and upgrading device. The device comprises a coal bunker 1, a drying device 2, a pyrolysis device 3, a combustion device 4 and a dehydration device 8, and the drying device is connected with the coal bunker and the pyrolysis device 3 respectively, and the dehydration device 8 is arranged on the combustion device 4 and the pyrolysis device 3, the drying device is divided into two parts, the flue gas drying chamber and the steam drying chamber. Connect with the steam outlet of the combustion device through the steam pipe.

[0021] The technological process and working principle of the present invention are as follows: the lignite is transported from the silo 1 to the drying device 2, and the moisture is removed under the separate heating of hot flue gas at a temperature of 100-150°C and steam at a temperature of 200-220°C. The dried lignite is sent into the fluidized bed pyrolysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com