Beta-elemi alkene bulk medicament and method of preparing its preparations

A technology of elemene and raw materials, applied in the field of preparation of β-elemene raw materials and its preparations, can solve the problems of high cost, complicated production equipment, and limited sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

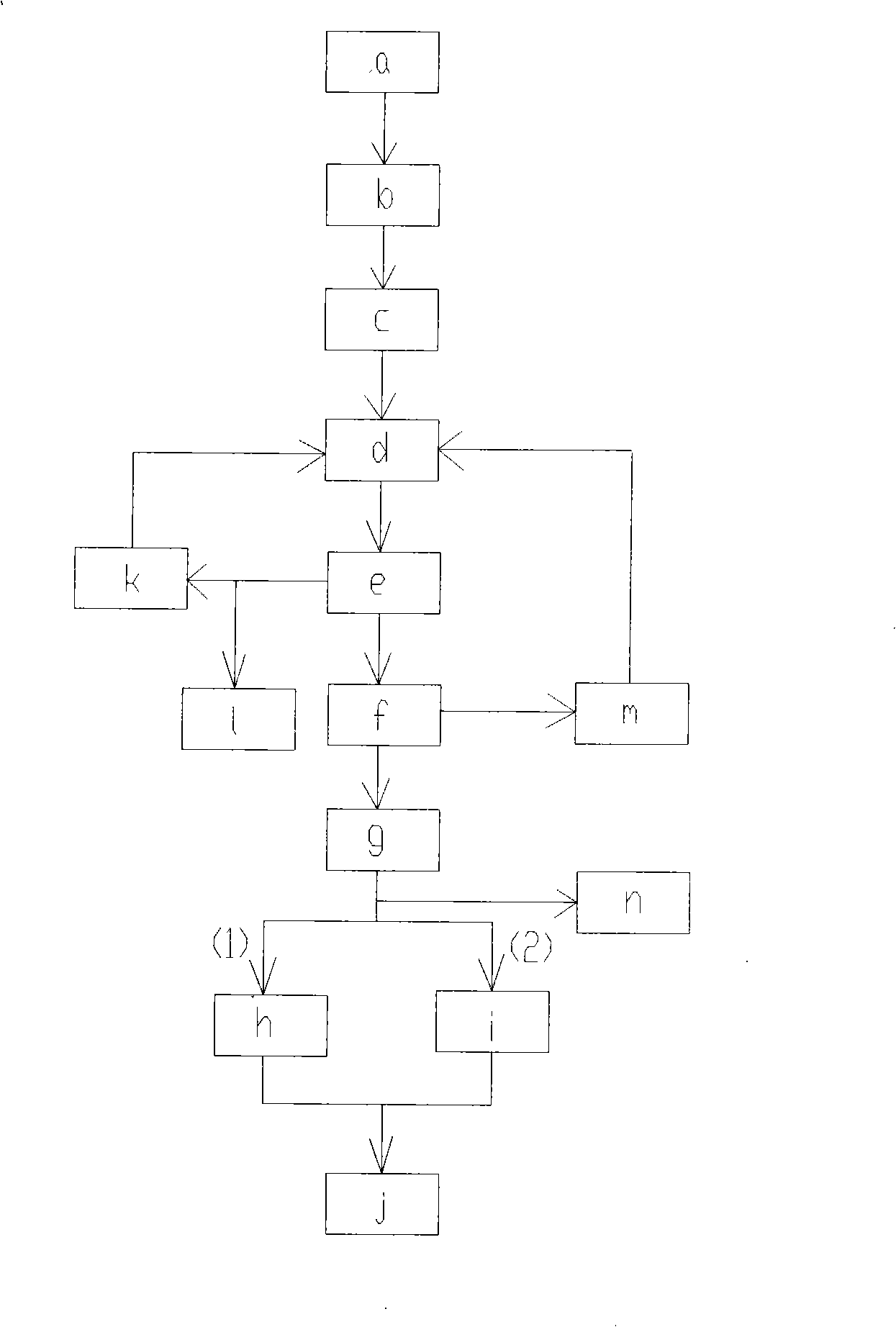

Method used

Image

Examples

Embodiment 1

[0023] A, get the natural herbal medicine curcuma tuber as raw material;

[0024] B, the medicinal material Zedoary is steam-distilled to obtain Zedoary volatile oil, wherein the content of β-elemene is 6.0%;

[0025] c. Put the raw material obtained in b into a molecular distillation device for distillation. The vacuum degree is 20Pa, the temperature of the tower is 60°C, the material flow rate is 3mL / min, the temperature of the condensation surface is 15°C, and the speed of the scraping film is 350rpm. The water temperature is 60°C, molecular distillation removes monoterpenes and sesquiterpenoids with low boiling points; °C, the rotating speed of the scraping film is 300 rpm, the temperature of the circulating water is 60 °C, molecular distillation is carried out, and the distillate is collected to obtain β-elemene with a content of 45.6%.

[0026] d. The 45.6% β-elemene sample obtained in step c was extracted three times with 70% ethanol aqueous solution having a five-fold...

Embodiment 2

[0030] a, taking the fresh leaves of natural plant Javanese citronella as raw material;

[0031] b. The medicinal material Javanese citronella is steam-distilled to obtain Javanese volatile oil, wherein the content of β-elemene is 5.0%;

[0032]c. Put the raw material obtained in b into a molecular distillation device for distillation. The vacuum degree is 30Pa, the temperature of the tower is 70°C, the material flow rate is 3mL / min, the temperature of the condensation surface is 15°C, and the speed of the scraping film is 400rpm. The water temperature is 65°C, molecular distillation removes monoterpenes and sesquiterpenoids with low boiling points; °C, the rotating speed of the scraping film was 350 rpm, and the temperature of the circulating water was 65 °C to carry out molecular distillation, and the distillate was collected to obtain β-elemene with a content of 48.6%.

[0033] d. The 48.6% β-elemene sample obtained in step c was extracted three times with quintuple volume...

Embodiment 3

[0037] a, taking the fresh leaves of natural plant Solidago as raw material;

[0038] b. Obtaining Solidago volatile oil by supercritical extraction from the leaves of Solidago, wherein the content of β-elemene is 16.0%;

[0039] c. Put the raw material obtained in b into a molecular distillation device for distillation. The vacuum degree is 30Pa, the temperature of the tower is 70°C, the material flow rate is 3mL / min, the temperature of the condensation surface is 15°C, and the speed of the scraping film is 450rpm. The water temperature is 65°C, molecular distillation removes monoterpenes and sesquiterpenoids with low boiling points; °C, the rotating speed of the scraping film is 400 rpm, and the temperature of the circulating water is 65 °C, molecular distillation is carried out, and the distillate is collected to obtain β-elemene with a content of 70.0%.

[0040] d. The 70.0% β-elemene sample obtained in step c was extracted three times with quintuple volume concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com