Automatic control method of iron ore flotation reagent dosage based on tailings grade

A flotation reagent and grade technology, applied in flotation, solid separation, etc., can solve the problems of inability to objectively describe the dosage of reagents by neural network, local optimization or overfitting of neural networks, and timely adjustment and control of closed-loop dosage of reagents. The effect of saving pharmaceutical dosage, avoiding local optimum or overfitting, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

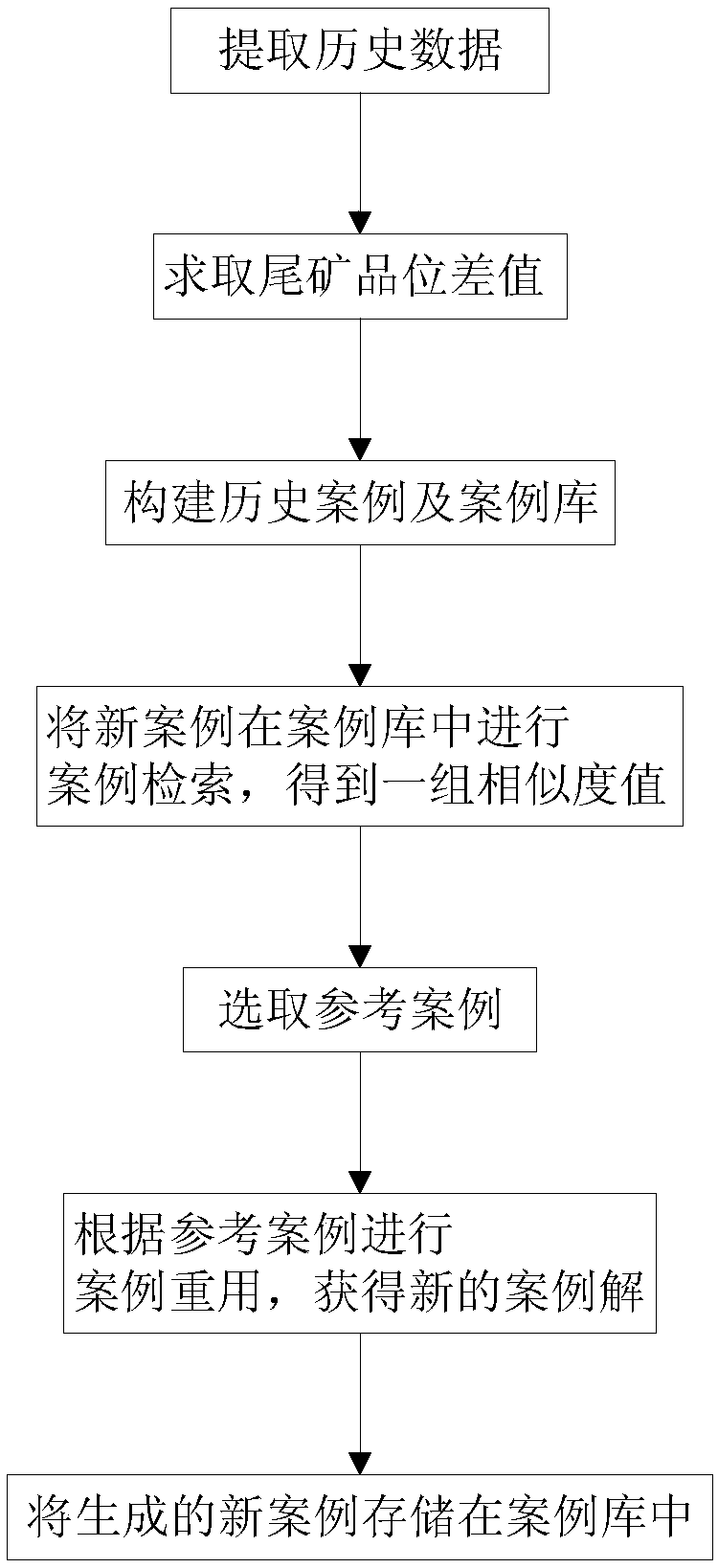

[0018] An automatic control method for the dosage of iron ore flotation reagents based on tailings grade, such as figure 1 shown, including the following steps:

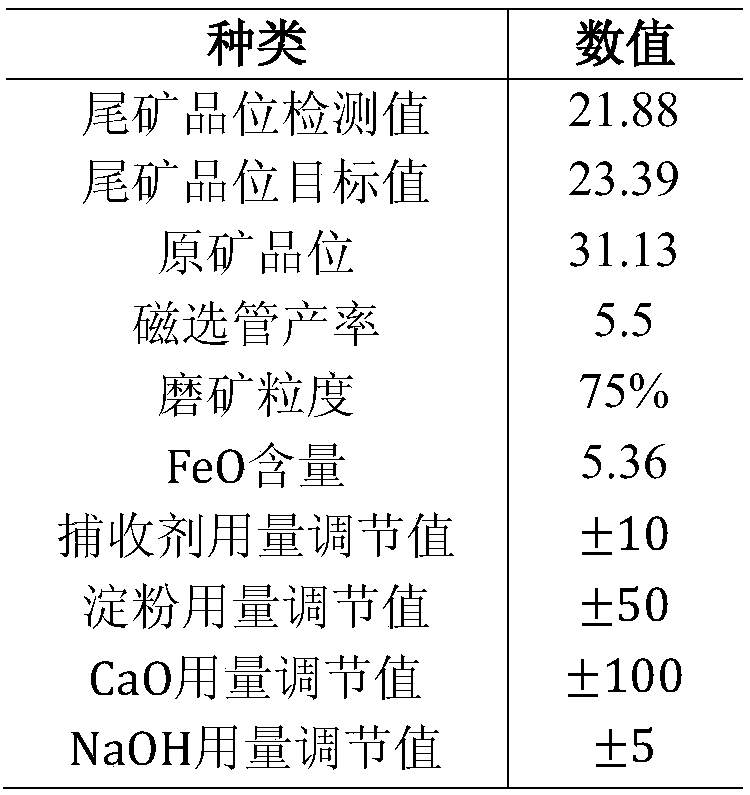

[0019] Step 1: Extract historical data from the iron ore flotation production process, including tailings grade detection value, tailings grade target value, raw ore grade, magnetic separation tube yield, grinding particle size, FeO content, collector dosage adjustment value , starch dosage adjustment value, CaO dosage adjustment value, NaOH dosage adjustment value, such as:

[0020]

[0021] Table 1

[0022] Step 2: Make a difference between the tailings grade detection value and the tailings grade target value, take its absolute value, and set this value as the tailings grade difference;

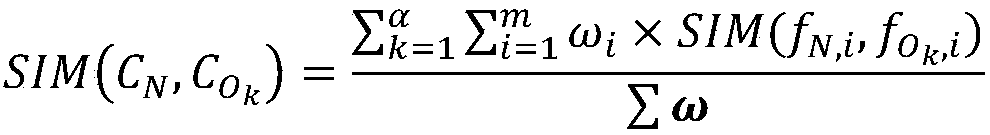

[0023] Let the detection value of tailings grade be T d , the tailings grade ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com