On-line control method and system for high-precision flat surface roughness of cold-rolled strip steel

A surface roughness and cold-rolled strip technology, which is applied in the field of cold-rolled strip steel, can solve problems such as roughness online control application technology research that has not yet been carried out, and achieve the effect of improving product quality and control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The production process of cold-rolled steel strip is: pickling-cold rolling-annealing-levelling-coating, cutting and packaging. Among them, the smoothing process has a great influence on the surface roughness of cold-rolled strip steel.

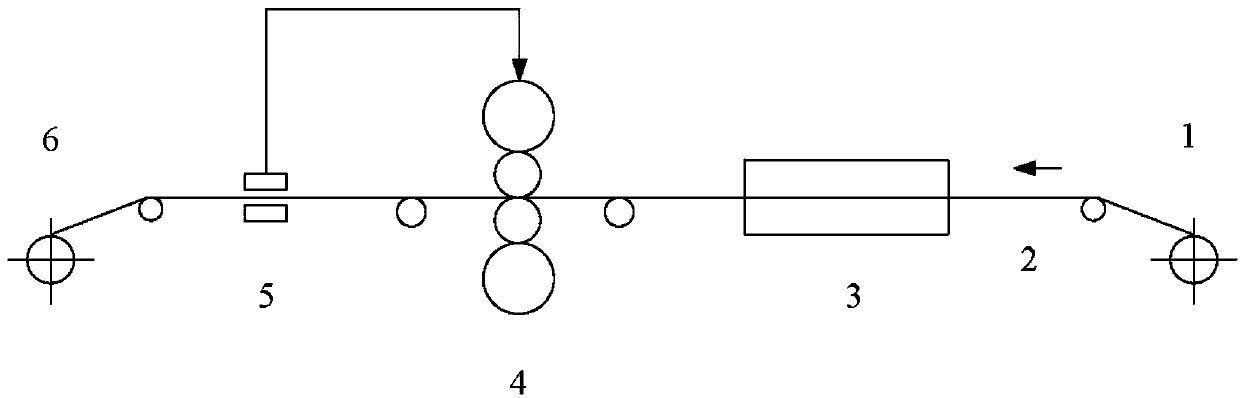

[0038] The surface roughness on-line control method provided by the present invention can be used in such as figure 1 completed on the device shown. Such as figure 1 As shown, after the strip steel 2 transmitted by the uncoiler 1 is processed by the continuous annealing furnace 3 and the tempering machine 4, it passes through the surface roughness on-line monitor 5, and the strip steel detected by the surface roughness on-line monitor 5 The measured value of the surface roughness m is compared with the target value required by the downstream user. If it meets the requirements of the downstream user, the strip 2 passes through the surface roughness on-line monitor 5 and enters the coiler 6, that is, enters the coating, shearing and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com