Control method of catalytic cracking device

A technology for a catalytic cracking unit and a control method, which is applied in the control field of a catalytic cracking unit, can solve problems such as reducing catalyst activity, and achieve the effects of improving production efficiency, operating safety, and running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The control method of a catalytic cracking unit of the present invention will be described in detail below with reference to the drawings and specific embodiments.

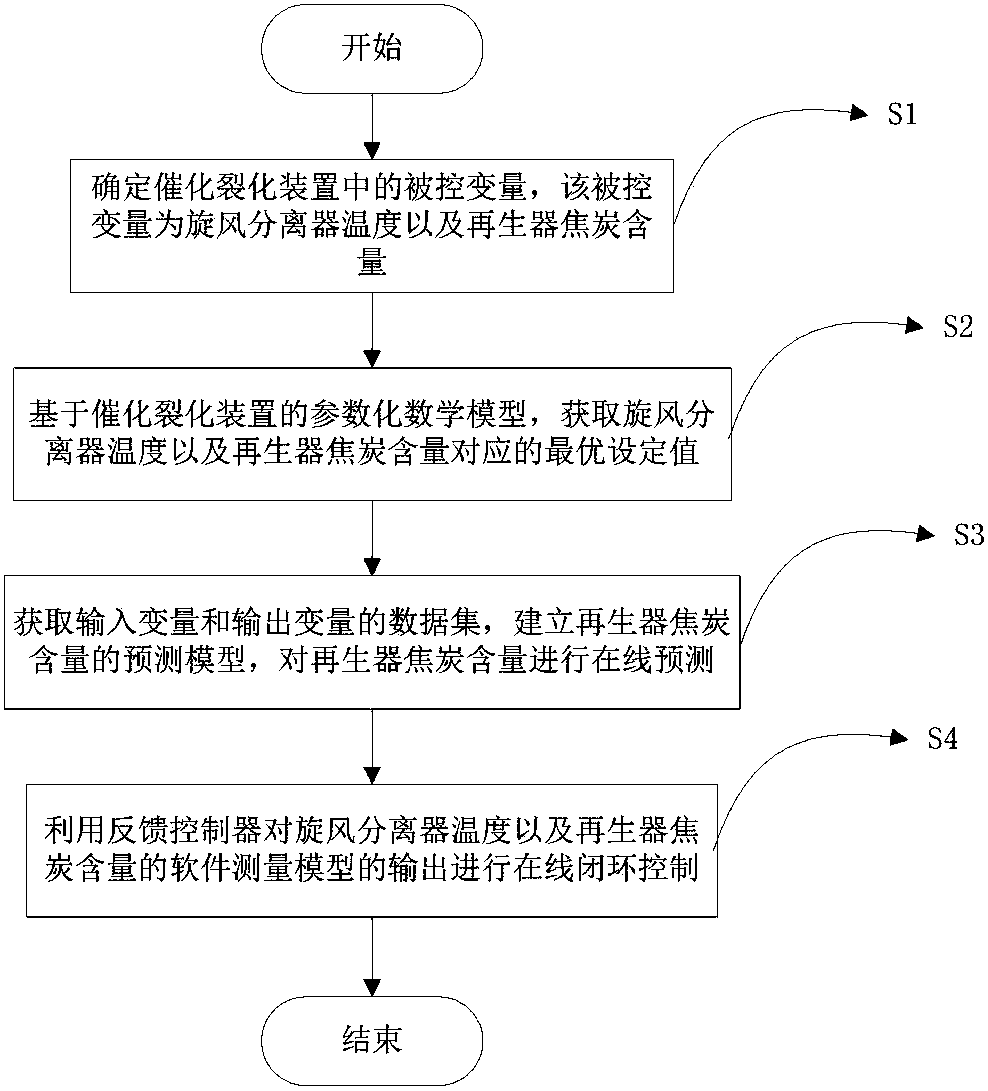

[0031] Such as figure 1 As shown, a control method of a catalytic cracking unit includes the steps:

[0032] S1. Determine the controlled variable in the catalytic cracking unit. The controlled variable is the temperature of the cyclone separator and the coke content of the regenerator;

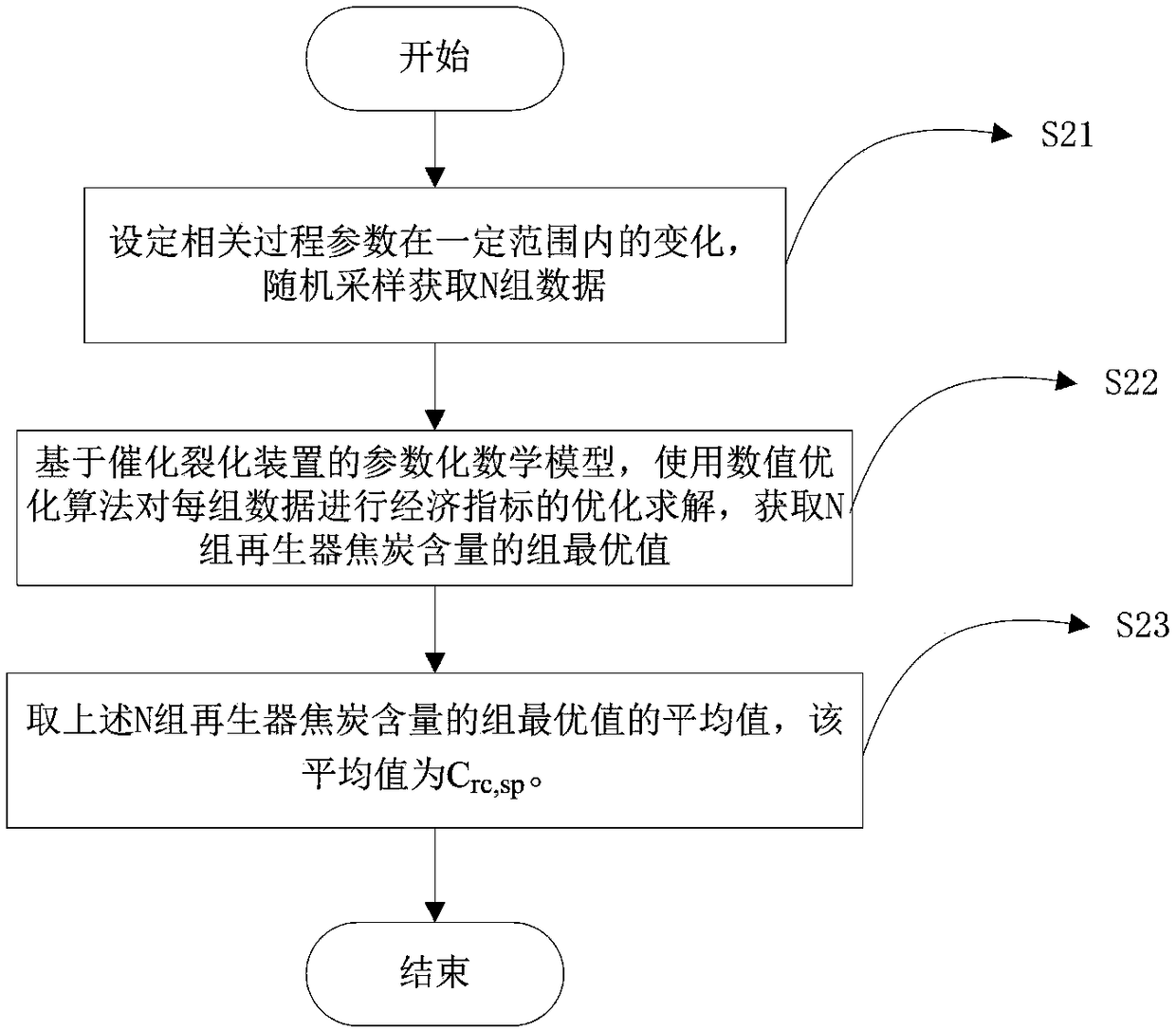

[0033] S2, based on the parameterized mathematical model of the catalytic cracking unit, obtain the optimal setting value corresponding to the temperature of the cyclone separator and the coke content of the regenerator;

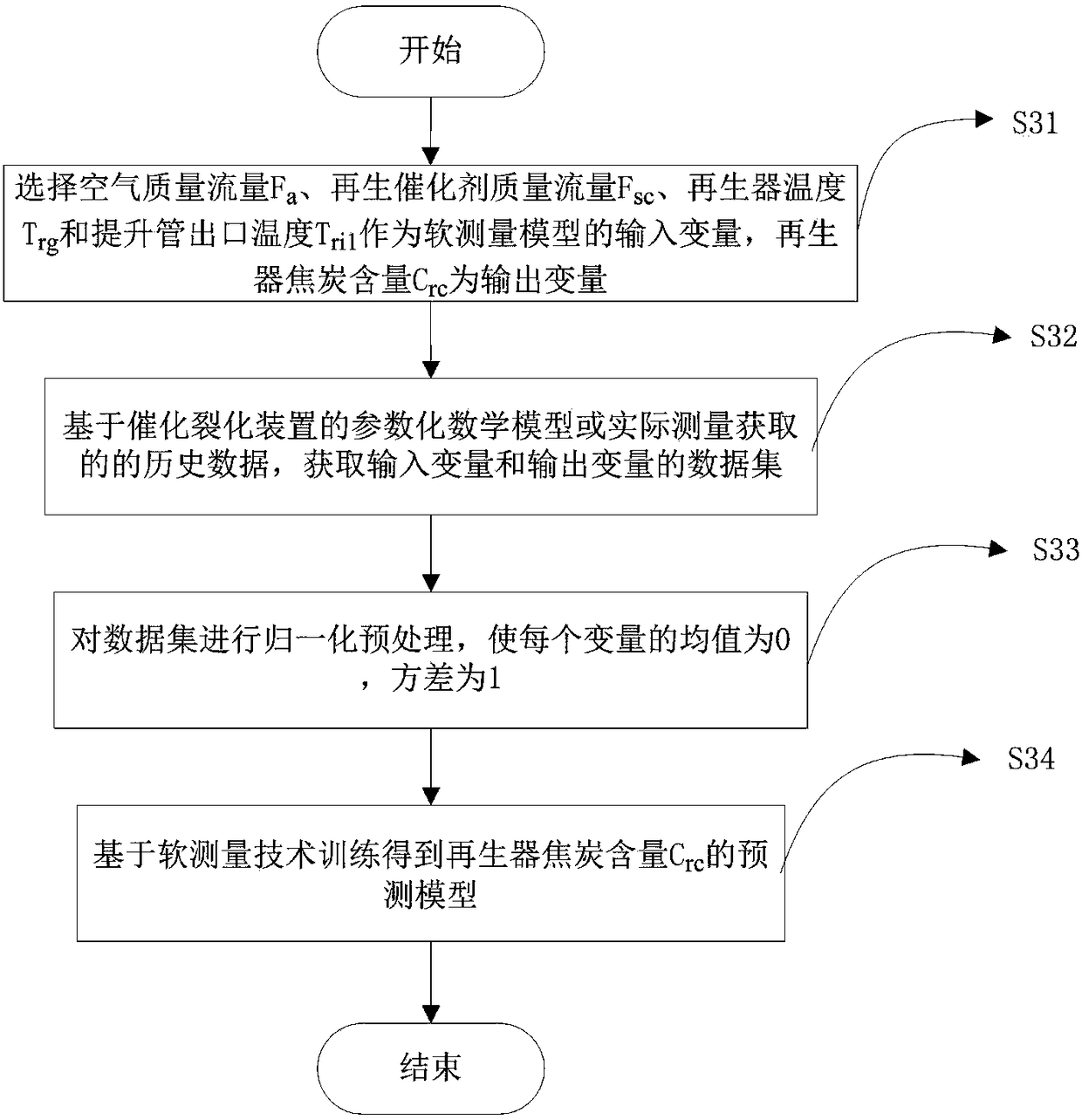

[0034] S3. Obtain a data set of input variables and output variables, establish a prediction model for the coke content of the regenerator, and perform online prediction for the coke content of the regenerator;

[0035] S4. Use the feedback controller to perform online closed-loop control on the output of the sof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com