Super-large-sized high-magnesium-content aluminum-alloy slab ingot and preparation method thereof

A technology with super-large size and manufacturing method, applied in the field of aluminum alloy processing, can solve the problems of coarse grains of ingot structure, easy cracking, easy generation of loose defects, etc., to achieve uniform microstructure of alloy, eliminate casting stress, and ingot mechanical properties. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

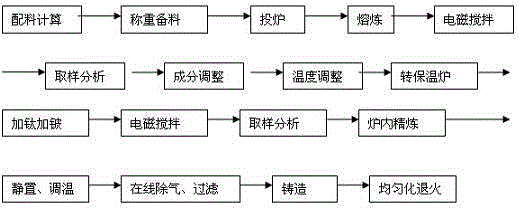

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, a super-sized 5XXX series aluminum alloy flat ingot is composed of Si<0.25%, Fe<0.30%, Cu<0.10%, Mn=0.60%~1.0%, Mg=4.45%~4.85%, by mass percentage, Cr=0.05%~0.22%, Zn<0.25%, Ti=0.005%~0.10%, Be=0.0002%~0.0015%, B<0.005%, Na<0.0003%, the rest is made of Al and other unavoidable impurities (Each impurity<0.05%, the total amount of other impurities<0.15%).

[0037] The present embodiment carries out according to the following steps:

[0038] 1. By mass percentage Si<0.25%, Fe<0.30%, Cu<0.10%, Mn=0.60%~1.0%, Mg=4.45%~4.85%, Cr=0.05%~0.22%, Zn<0.25%, Ti =0.005%~0.10%, Be=0.0002%~0.0015%, B<0.005%, Na<0.0003%, and the rest is Al, respectively weighing aluminum ingots for remelting, aluminum-manganese intermediate alloys, pure magnesium ingots, and aluminum-chromium intermediates alloy, aluminum-titanium master alloy, aluminum-beryllium master alloy, etc., and then add aluminum ingots for remelting, aluminum-manganese master alloys, pure magnesium ingots,...

Embodiment 2

[0046] In this embodiment, a super-sized 5XXX series aluminum alloy flat ingot consists of Si<0.12%, Fe<0.20%, Cu<0.15%, Mn=0.30%~0.45%, Mg=4.0%~4.5%, by mass percentage, Cr<0.08%, Zn<0.20%, Ti=0.002%~0.008%, Be=0.0002%~0.0008%, B<0.005%, Na<0.0003%, the rest is made of Al and other unavoidable impurities (each Impurities <0.05%, other impurities total <0.15%).

specific Embodiment 1

[0047] This embodiment is carried out according to the following steps (except steps 1 and 5, all the other steps are the same as in specific embodiment 1):

[0048] 1. By mass percentage Si<0.12%, Fe<0.20%, Cu<0.15%, Mn=0.30%~0.45%, Mg=4.0%~4.5%, Cr<0.08%, Zn<0.20%, Ti=0.002% ~0.008%, Be=0.0002%~0.0008%, B<0.005%, Na<0.0003%, and the rest is Al. Weigh aluminum ingot for remelting, aluminum-manganese master alloy, pure magnesium ingot, aluminum-chromium master alloy, aluminum-titanium Master alloys, aluminum-beryllium master alloys, etc., and then add aluminum ingots for remelting, aluminum-manganese master alloys, pure magnesium ingots, and aluminum-chromium master alloys into a dry melting furnace for smelting into molten aluminum. Turn on the electromagnetic stirrer for full stirring during the smelting process.

[0049] 5. Use the DC semi-continuous casting method to cast super-sized 5XXX series aluminum alloy flat ingots of 650mm thick x 2670mm wide x 8000mm long. Liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com