Non-cooperative target docking mechanism with peripheral swing-rod-type expansion joint

A non-cooperative target and docking mechanism technology, applied in the field of non-cooperative target docking mechanism, can solve the problems of heavy weight, large size, complex structure, etc., and achieve the effect of light weight, high integration, and simple drive control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

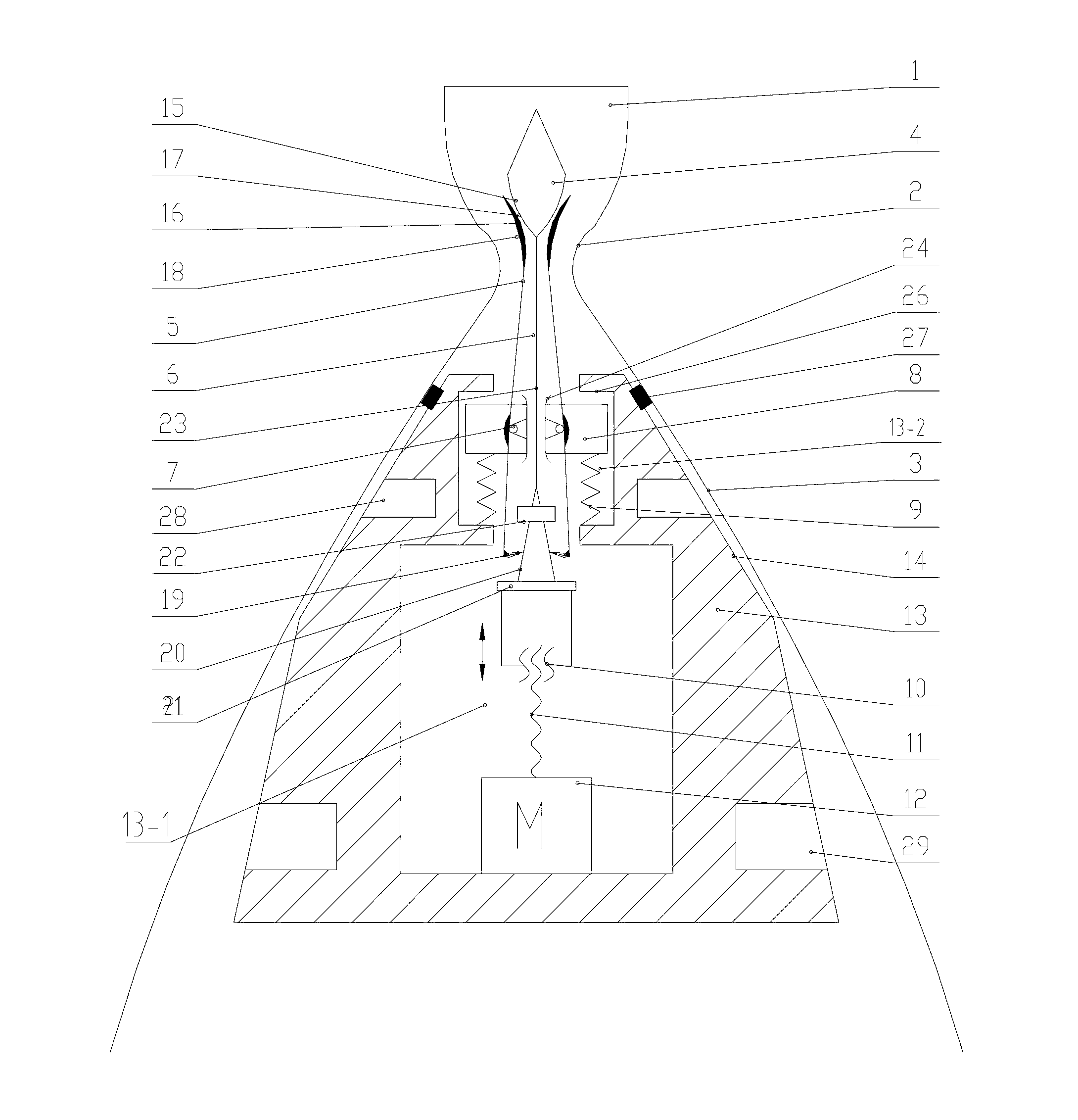

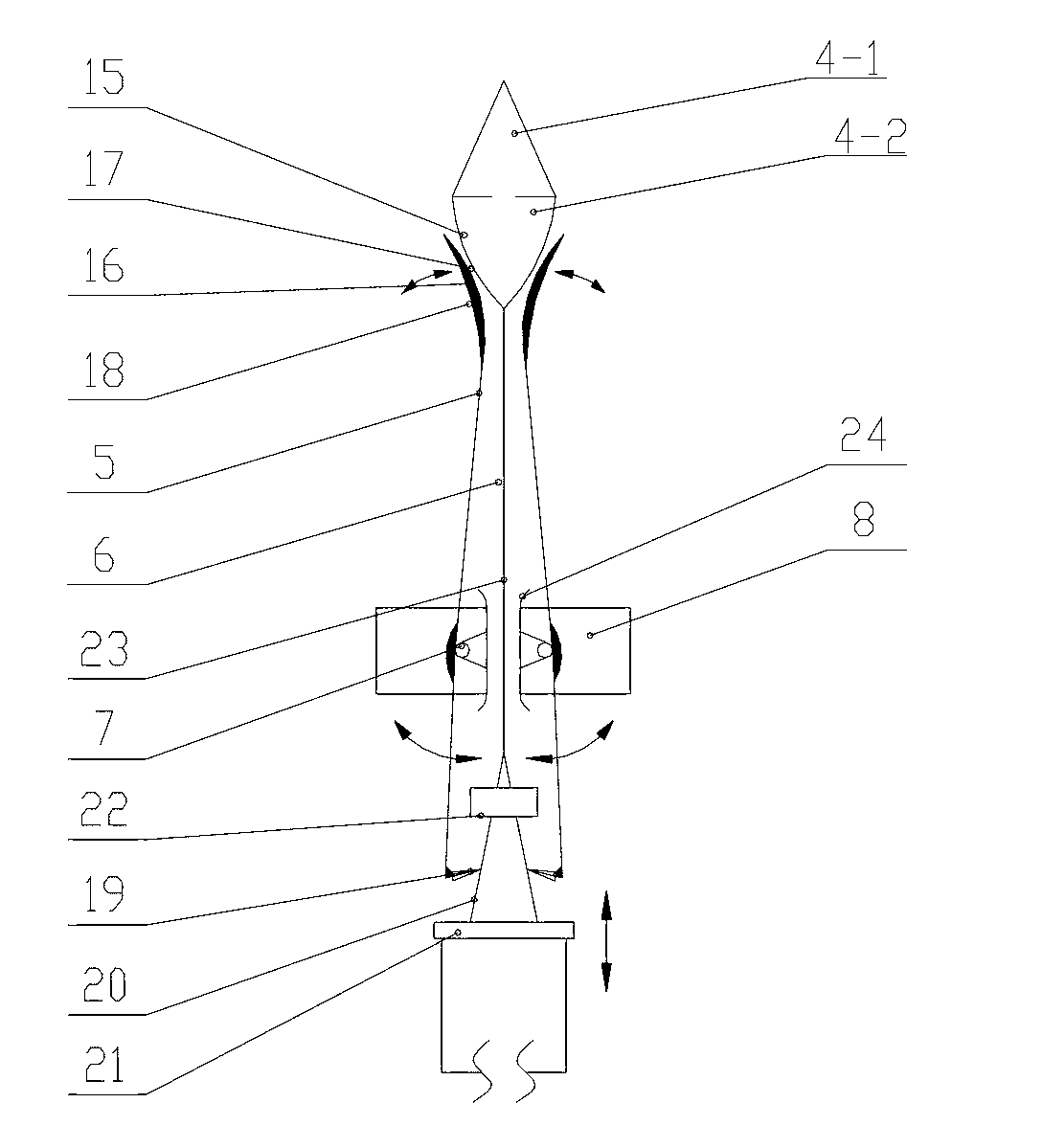

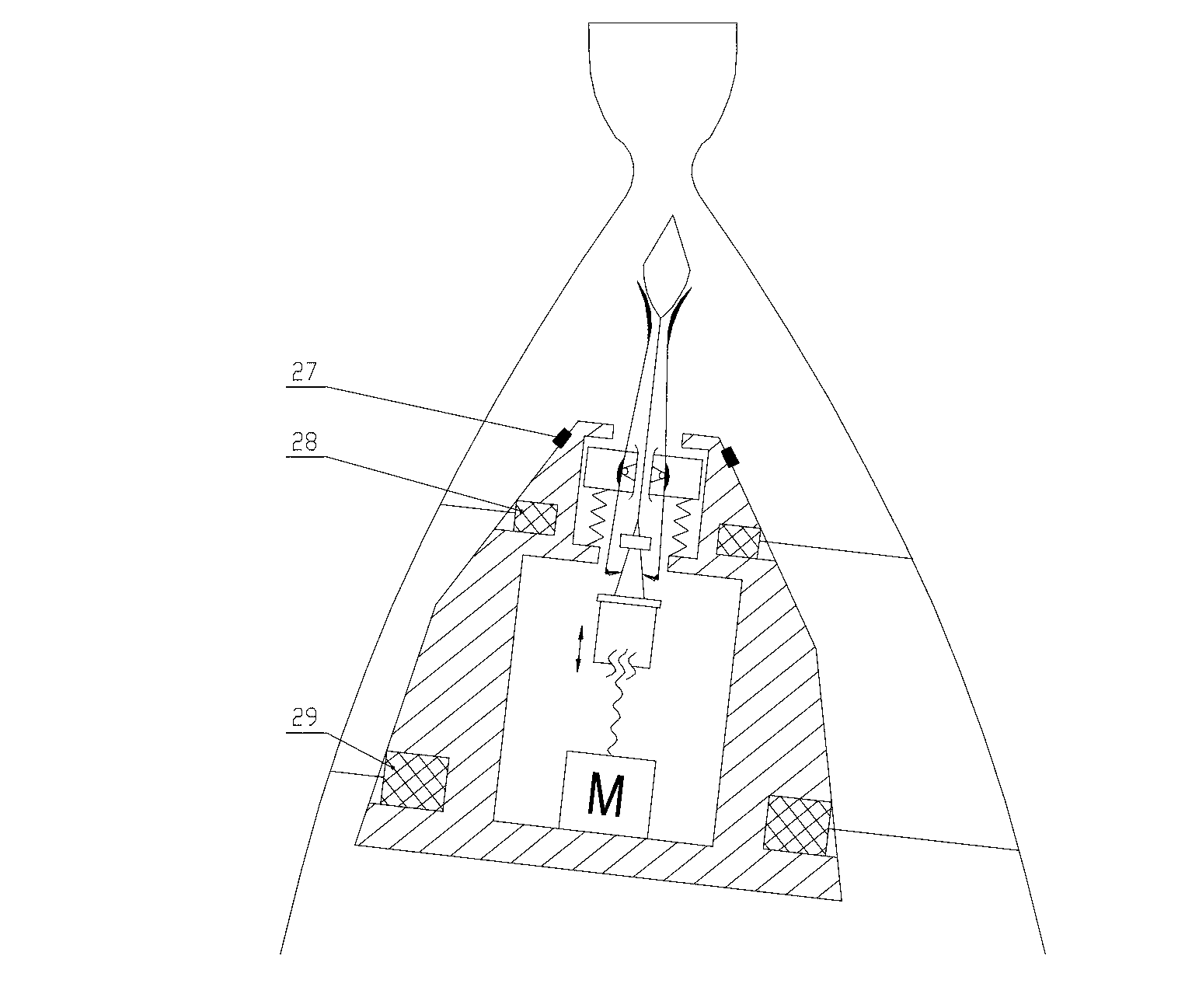

[0008] Specific implementation mode one: combine Figure 1-Figure 5 Describe this embodiment, the mechanism of this embodiment includes a cone top 4, a swing rod shaft 7, a locking slider 8, a return spring 9, a screw nut 10, a screw 11, a motor 12, a housing 13, a swing rod top 16, Fork hook 19, cone slide 20, lower limiter 21, upper limiter 22, slide bar 23, sleeve 24, slide limiter 26 and a plurality of fork 5, cone top 4 is formed by upper cone 4- 1 and the bottom surface of the lower cone 4-2 are butted into one body, the first groove 13-1 and the second groove 13-2 are arranged in the housing 13 and both the first groove 13-1 and the second groove 13-2 Connected, the upper part of the first groove 13-1 is provided with a sliding limiter 26, the upper part of the housing 13 is provided with a pressing surface 14 matching the inner wall of the nozzle 1, and the motor 12 is fixed in the first groove 13-1. 1, the output end of the motor 12 is rotationally connected to one e...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 To describe this embodiment, the number of swing bars 5 in this embodiment is 3-5. After the casing 13 presses the inner wall 3 of the diffuser section of the nozzle 1, the cone top 4 presses the swing rod top 16 to the throat 2 of the nozzle 1, and the number of swing rods 5 is 3-5, which can meet the pressing function needs. Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 Describe this embodiment, the pretightening force of the back-moving spring 9 of this embodiment is 5-10N, has guaranteed the frictional force of swing rod top inner surface 17 and cone top sliding surface 15 and the friction of swing rod hook 19 and cone slider 20 The resultant force of the force is smaller than the reset force applied to the locking slider 8 by the reset spring 9 . Other implementation manners are the same as the specific implementation manner 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com