Super-hydrophobic conductive fiber, fabric and preparing method and use

A technology of conductive fiber and conductive fabric, which is applied in the processing field of functional materials, can solve the problems of fabric cleaning and maintenance costing a lot of manpower and material resources, and the conductivity affecting normal use, etc., to achieve the effect of simple operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1, prepare superhydrophobic conductive fabric of the present invention

[0053]At -50°C, a fabric of 2cm×2cm natural cotton fibers was placed in a tetrahydrofuran solution containing aniline (conductive polymer monomer), benzoyl peroxide (oxidant) and perfluorosuberic acid (dopant) In, wherein, the molar ratio of aniline and benzoyl peroxide is 1:1, the concentration of perfluorosuberic acid is 0.01mol / L, and the reaction time is 10 hours, and the aniline monomer is oxidatively polymerized on the surface of the natural cotton fiber fabric, The fabric with superhydrophobic and conductive properties of the present invention is obtained.

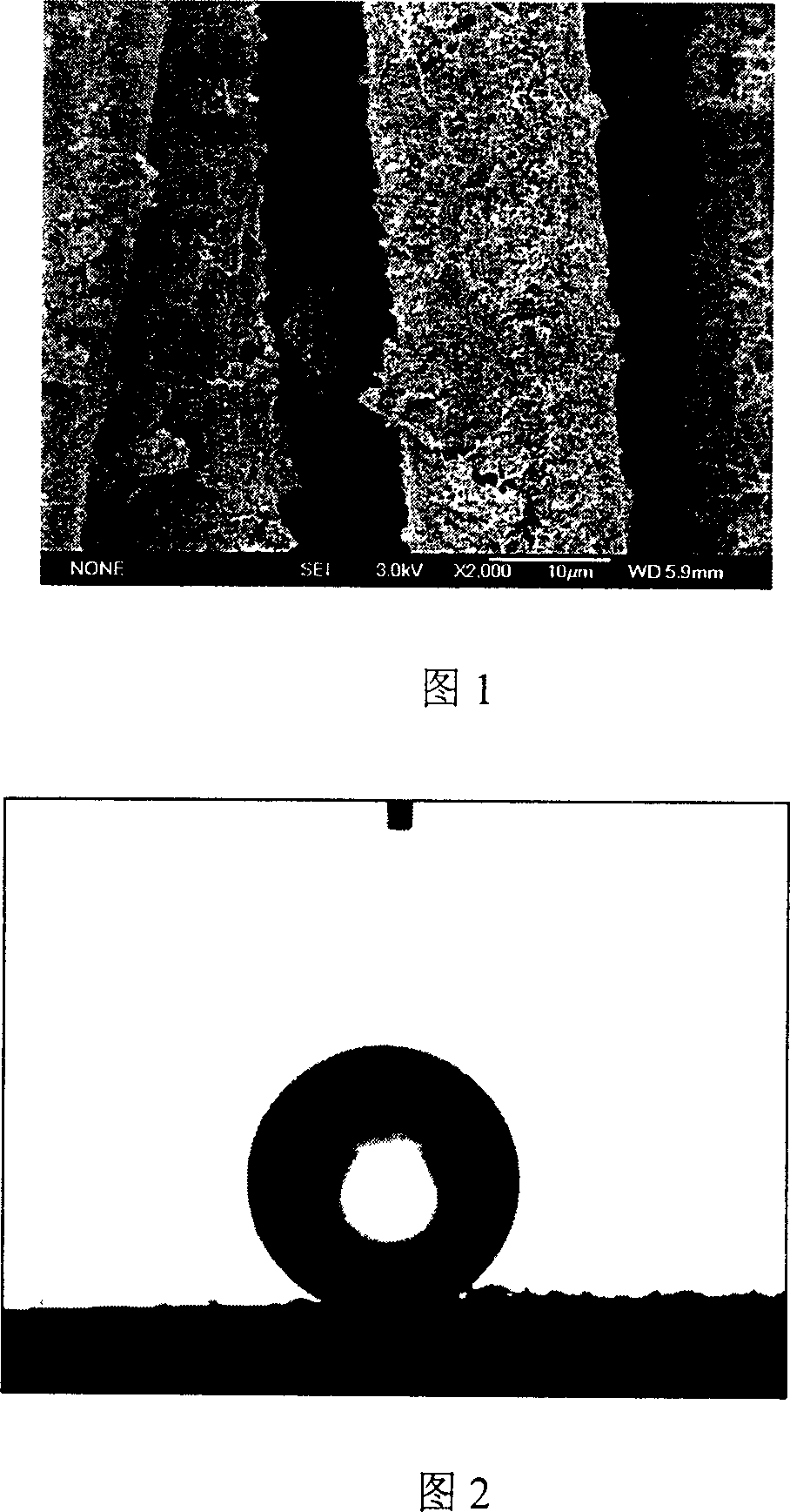

[0054] The scanning electron microscope photo of the super-hydrophobic conductive fabric is shown in Figure 1. The surface of the fabric is coated with a polyaniline layer with a thickness of 20 nanometers, and the polyaniline layer is composed of polyaniline particles with a diameter of 500-900 nanometers.

[0055] The stati...

Embodiment 2

[0057] Embodiment 2, preparation superhydrophobic conductive fabric of the present invention

[0058] At 50°C, place a 2cm×2cm viscose fiber fabric in water containing pyrrole (conductive polymer monomer), ammonium persulfate (oxidant) and perfluorosuberic acid (dopant), wherein pyrrole The molar ratio with ammonium persulfate is 1: 40, the concentration of perfluorosuberic acid is 10mol / L, and the reaction time is 24 hours. The pyrrole monomer is oxidatively polymerized on the surface of the viscose fiber fabric to obtain the superhydrophobic and Fabric with conductive properties.

[0059] The surface of the super-hydrophobic conductive fabric is coated with a polypyrrole layer with a thickness of 1000 nanometers, and the polypyrrole layer is composed of polypyrrole particles with a diameter of 400-900 nanometers.

[0060] The surface resistance of the superhydrophobic conductive fabric is 200Ω / cm 2 , the contact angle with water is 173.2°, and the rolling angle is 5°, show...

Embodiment 3

[0061] Embodiment 3, preparation superhydrophobic conductive fabric of the present invention

[0062] At 20°C, a fabric of 2cm×2cm polyester fiber was placed in a chloroform solution containing 3-hexylthiophene (conductive polymer monomer), ferric chloride (oxidant) and perfluorooctanoic acid (dopant), wherein, The molar ratio of 3-hexylthiophene to ferric chloride is 1:30, the concentration of perfluorooctanoic acid is 6mol / L, and the reaction time is 10 hours, and the 3-hexylthiophene monomer is oxidatively polymerized on the surface of synthetic polyester fabric to obtain the present invention with Fabric with superhydrophobic and conductive properties.

[0063] The surface of the super-hydrophobic conductive fabric is coated with a poly-3-hexylthiophene layer with a thickness of 70 nanometers, and the poly-3-hexylthiophene layer is composed of poly-6-hexylthiophene particles with a diameter of 500-800 nanometers.

[0064] The surface resistance of the superhydrophobic con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com