Preparation method of bendable polylactic acid transparent conductive film

A transparent conductive film, polylactic acid technology, applied in the conductive layer on the insulating carrier, conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, etc., can solve the problem of mechanical and electrical performance degradation, instability, Problems such as uneven dispersion of graphene, to achieve the effect of simple preparation method, control thickness, and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

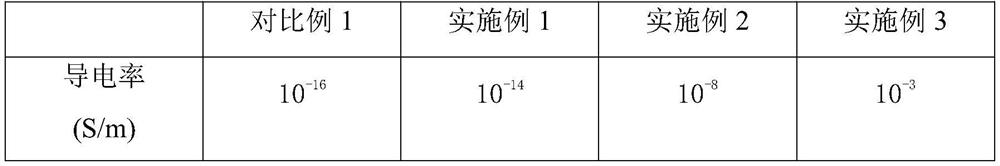

Embodiment 1

[0024] The molecular weight is M w The polylactic acid of =212921 is added to the chloroform solvent at a concentration of 0.05-0.5g / ml, and dissolved at 25°C for 24 hours; the graphene oxide aqueous solution is added to the tetrahydrofuran or chloroform solvent to make it uniformly dispersed at 25°C. Pour the above graphene oxide solution into the polylactic acid solution so that the mass fraction of the polylactic acid is 0.5wt%, and stir evenly at 50-70° C. to reduce the graphene. Polylactic acid / graphene films with different thicknesses were prepared by spin coating and dried in a vacuum oven for 24 hours.

Embodiment 2

[0026] The molecular weight is M w The polylactic acid of =212921 is added to the chloroform solvent at a concentration of 0.05-0.5g / ml, and dissolved at 25°C for 24 hours; the graphene oxide aqueous solution is added to the tetrahydrofuran or chloroform solvent to make it uniformly dispersed at 25°C. Pour the above graphene oxide solution into the polylactic acid solution so that the mass fraction of the polylactic acid is 1.5 wt%, and stir evenly at 50-70° C. to reduce the graphene. Polylactic acid / graphene films with different thicknesses were prepared by spin coating and dried in a vacuum oven for 24 hours.

Embodiment 3

[0028] The molecular weight is M w The polylactic acid of =212921 is added to the chloroform solvent at a concentration of 0.05-0.5g / ml, and dissolved at 25°C for 24 hours; the graphene oxide aqueous solution is added to the tetrahydrofuran or chloroform solvent to make it uniformly dispersed at 25°C. Pour the above graphene oxide solution into the polylactic acid solution so that the mass fraction of the polylactic acid is 3.5wt%, and stir evenly at 50-70° C. to reduce the graphene. Polylactic acid / graphene films with different thicknesses were prepared by spin coating and dried in a vacuum oven for 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com