Method for preparing balloon surface ablation electrode by using piezoelectric spraying manner

An ablation electrode and balloon technology, applied in the medical field, can solve problems such as unsatisfactory ablation effect, insufficient contact between catheter and ablation tissue, etc., and achieve the effect of increasing ablation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

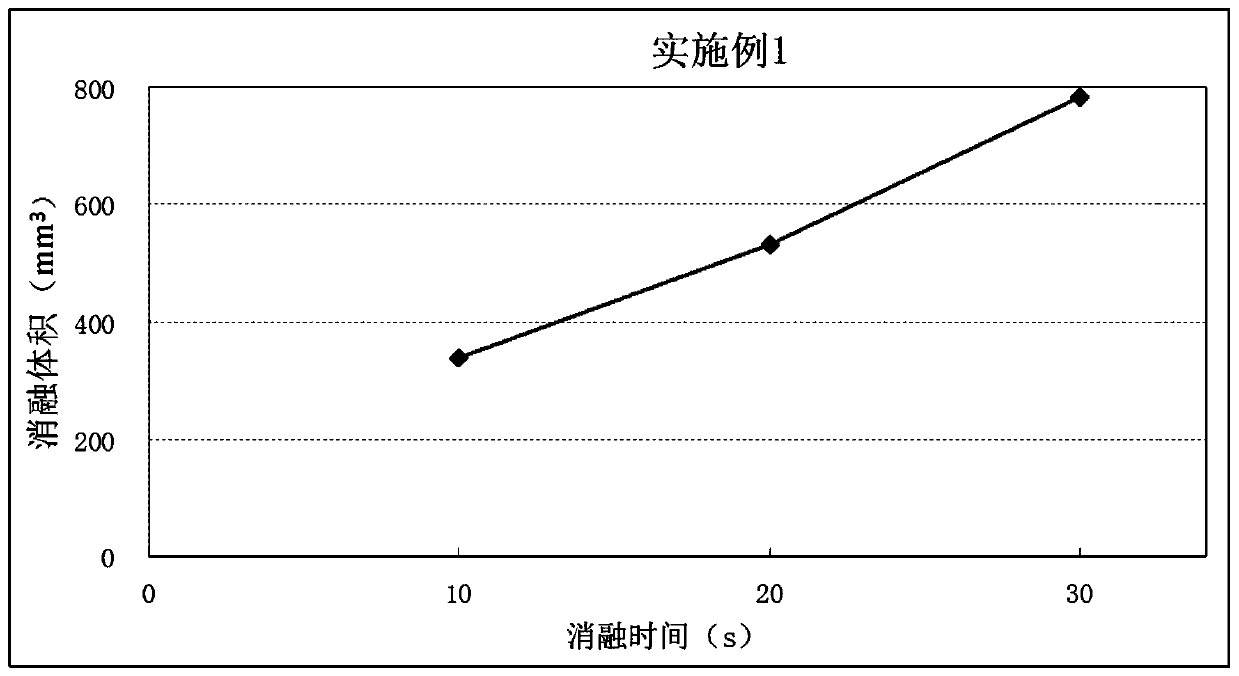

Embodiment 1

[0035] Select a nano-silver solution with a mass ratio of 30% and a viscosity of 15cP, put the container containing the nano-silver solution in a water bath and ultrasonically 120s to disperse the nano-silver particles evenly, then use a syringe to take out 2mL and pass it through a 0.45μm filter Inject it into the liquid reservoir of the jetlab4 piezoelectric spraying system, and spray it on the surface of the balloon that has been pretreated and heated in a water bath at 90°C according to the following spraying parameters: the diameter of the piezoelectric nozzle is 30 μm, the voltage amplitude is 40 V, and the piezoelectric cycle The time is 20μs, and the number of sprayed layers is 5 layers. The sprayed electrodes were dried in an electric thermostatic incubator at 120°C for 20 minutes, and finally the balloon surface ablation electrodes were obtained.

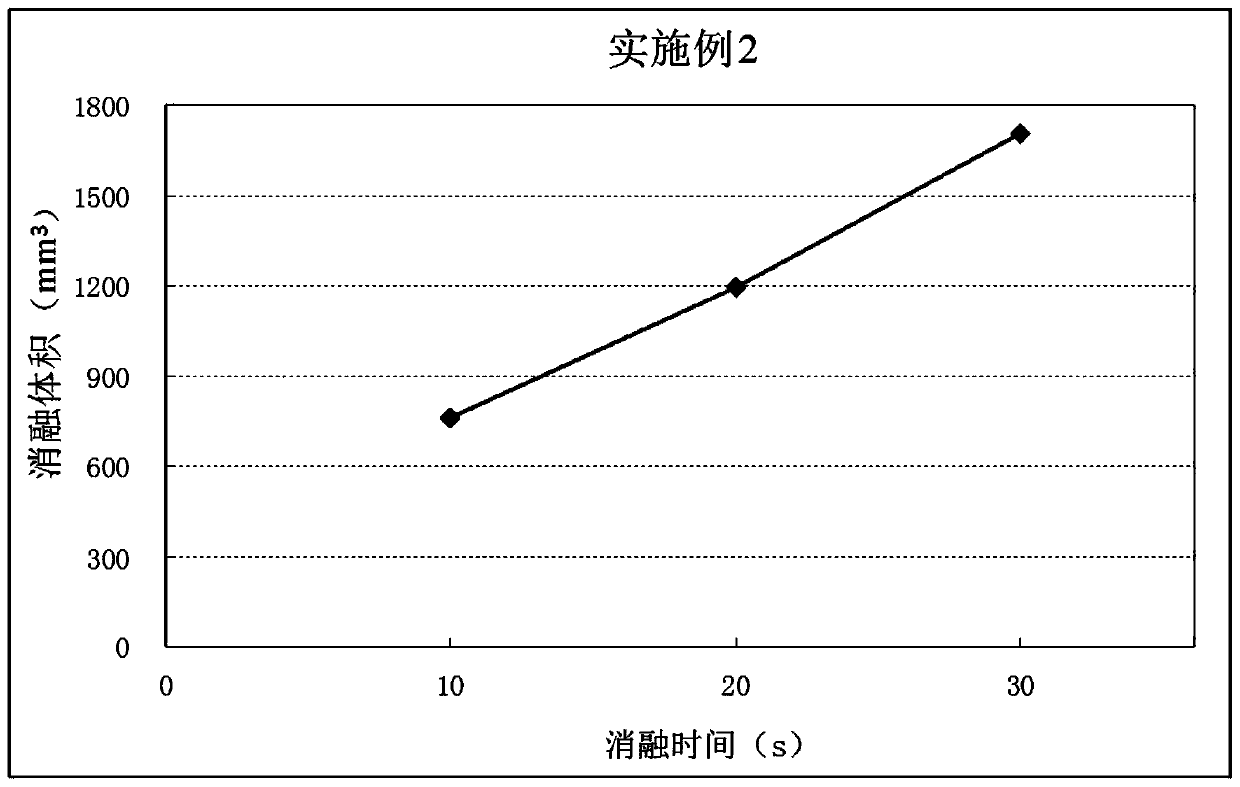

Embodiment 2

[0037] Select a nano-silver solution with a mass ratio of 30% and a viscosity of 15cP, put the container containing the nano-silver solution in a water bath and ultrasonically 120s to disperse the nano-silver particles evenly, then use a syringe to take out 2mL and pass it through a 0.45μm filter Inject it into the liquid reservoir of the jetlab4 piezoelectric spraying system, and spray it on the surface of the balloon that has been pretreated and heated in a water bath at 90°C according to the following spraying parameters: the diameter of the piezoelectric nozzle is 30 μm, the voltage amplitude is 40 V, and the piezoelectric cycle The time is 20μs, and the number of sprayed layers is 5 layers. The sprayed electrodes were dried in an electric thermostat incubator at 120°C for 25 minutes, and the balloon surface ablation electrodes were finally obtained.

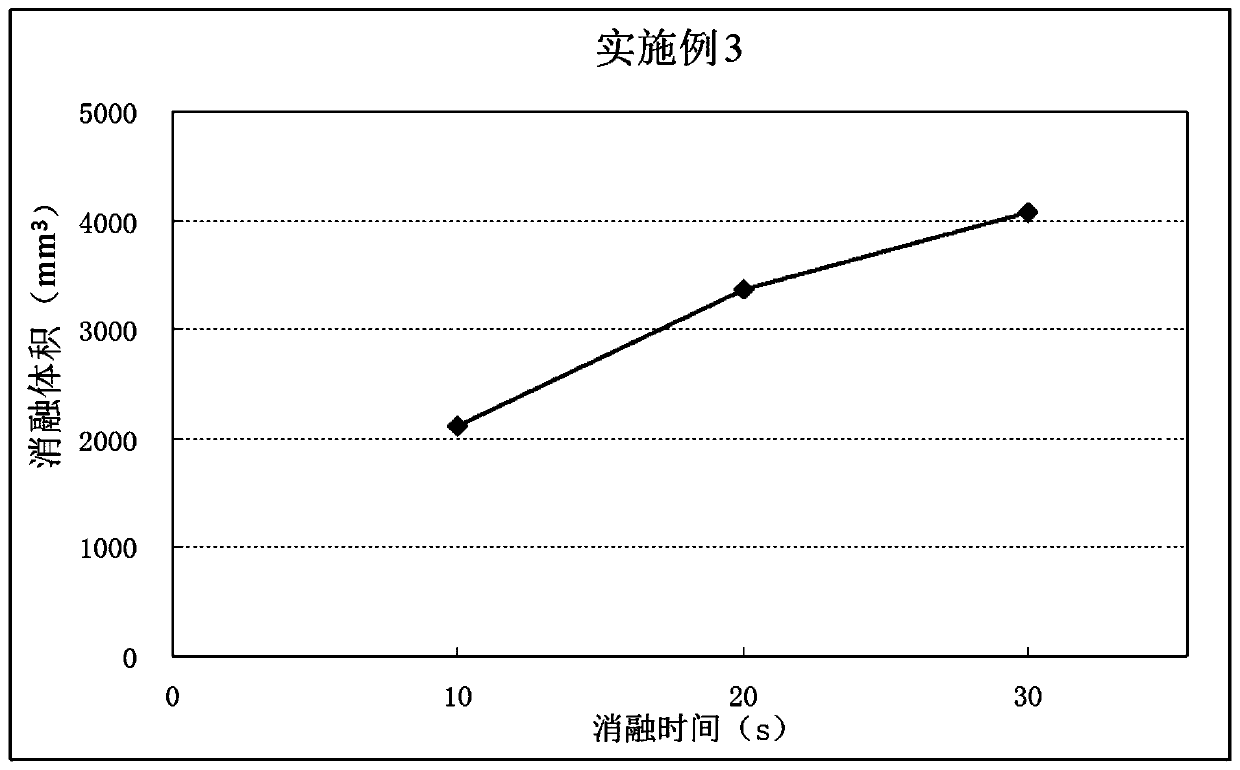

Embodiment 3

[0039]Select a nano-silver solution with a mass ratio of 30% and a viscosity of 15cP, put the container containing the nano-silver solution in a water bath and ultrasonically 120s to disperse the nano-silver particles evenly, then use a syringe to take out 2mL and pass it through a 0.45μm filter Inject it into the liquid reservoir of the jetlab4 piezoelectric spraying system, and spray it on the surface of the balloon that has been pretreated and heated in a water bath at 90°C according to the following spraying parameters: the diameter of the piezoelectric nozzle is 30 μm, the voltage amplitude is 40 V, and the piezoelectric cycle The time is 20μs, and the number of sprayed layers is 5 layers. The sprayed electrodes were dried in an electric thermostatic incubator at 120°C for 30 minutes, and finally the balloon surface ablation electrodes were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com