Patents

Literature

36results about How to "Control thermal conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

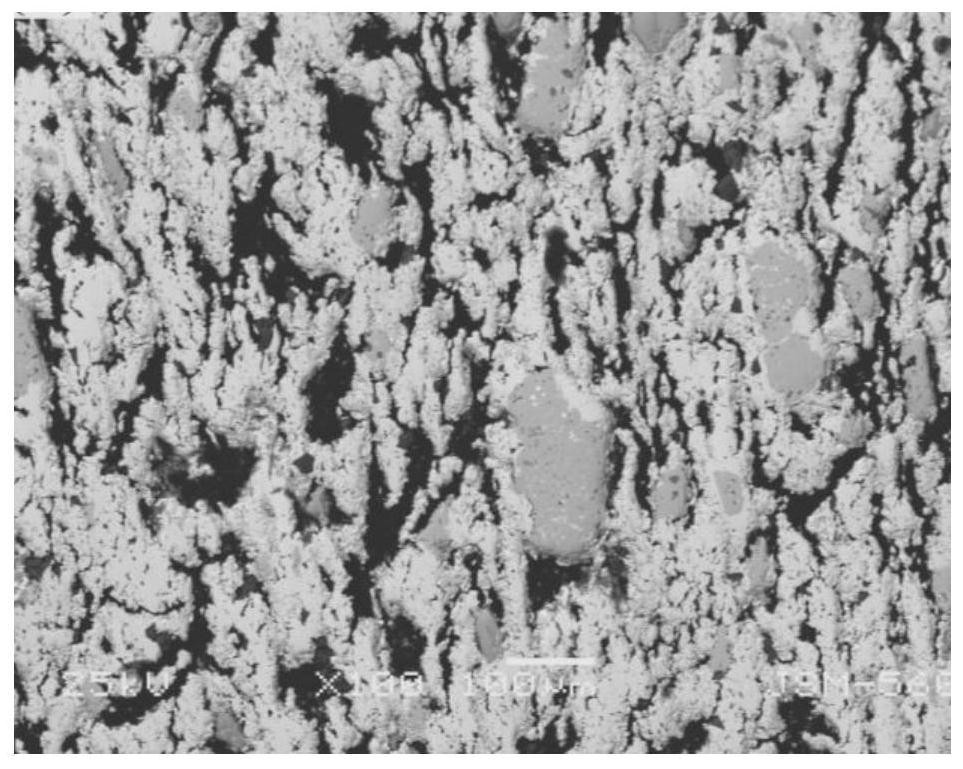

Heterogeneous mesoporous composite material thermophysical property calculating method

InactiveCN102944574APerfect thermal conductivityEffective vapor phase thermal conductivityMaterial heat developmentKnowledge FieldKinetic theory

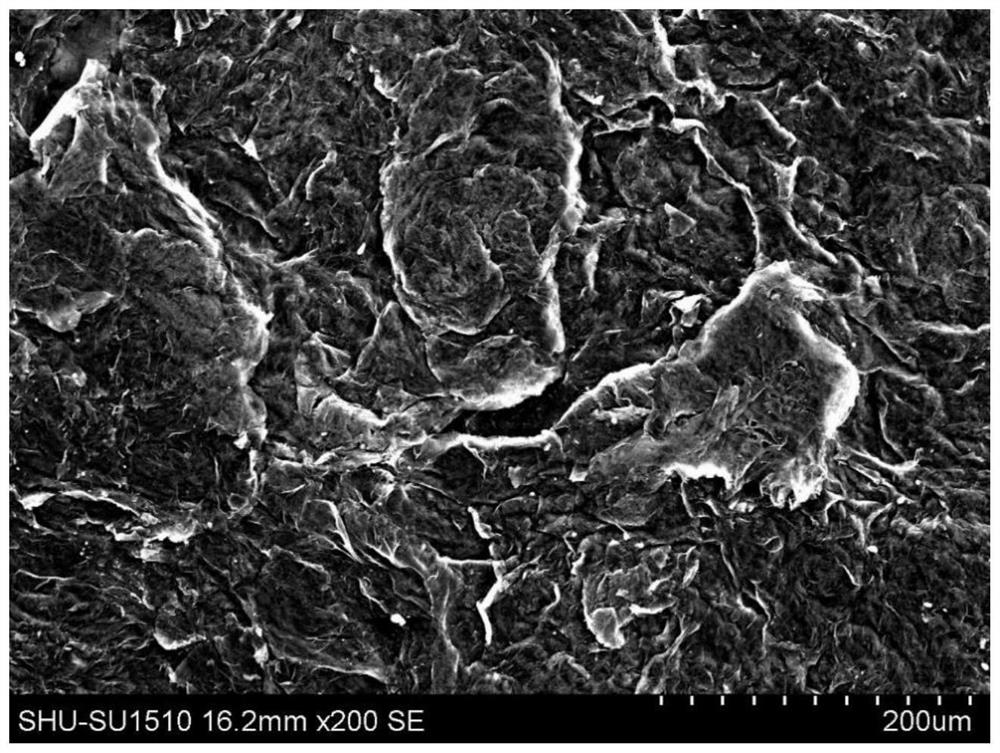

The invention relates to the research field of composite material property, in particular to a heterogeneous mesoporous composite material thermophysical property calculating method. The method includes the steps of: sample characterization: characterizing the properties of structure and composition of the composite material; thermophysical property testing: conducting thermophysical property testing on the composite material to measure values of thermal conductivity of all samples; theoretical calculation of the thermophysical property: respectively abstracting thermal conductivities of base material and filler of the heterogeneous mesoporous composite material to obtain the effective thermal conductivity by adopting kinetic theory in combination with molecular dynamics simulation, wherein near-field radiation, interface scattering as well as the coupling effect between the base material and the filler are taken into account; verification: in combination with the test result, further completing a relevant diathermanous mathematical model of the heterogeneous mesoporous composite material under nanometer pore size. Compared with the prior art, the heterogeneous mesoporous composite material thermophysical property calculating method disclosed by the invention solves the problem of solving the physical property parameters of the composite material under nanometer pore size, the accuracy of the thermophysical property is improved and material design is optimized.

Owner:UNIV OF SCI & TECH BEIJING

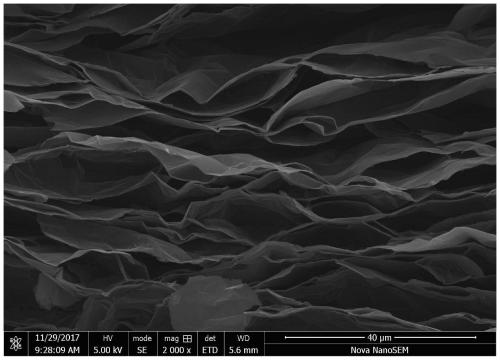

Graphene foam and preparation method thereof, graphene carbon composite material and preparation method thereof

PendingCN110357076AFast heat conductionImprove controllabilityGrapheneHeat-exchange elementsCarbon compositesCvd graphene

The invention provides a graphene foam and a preparation method thereof, and a graphene carbon composite material and a preparation method thereof. The graphene carbon composite material comprises graphene and a carbon material filled between the layers of graphene. According to the invention, the graphene carbon composite material with different heat conduction properties can be set according todifferent content of graphene and carbon. The graphene carbon composite material provided by the invention has very high heat conduction performance along a targeted direction.

Owner:CHANGZHOU FUXI TECH CO LTD

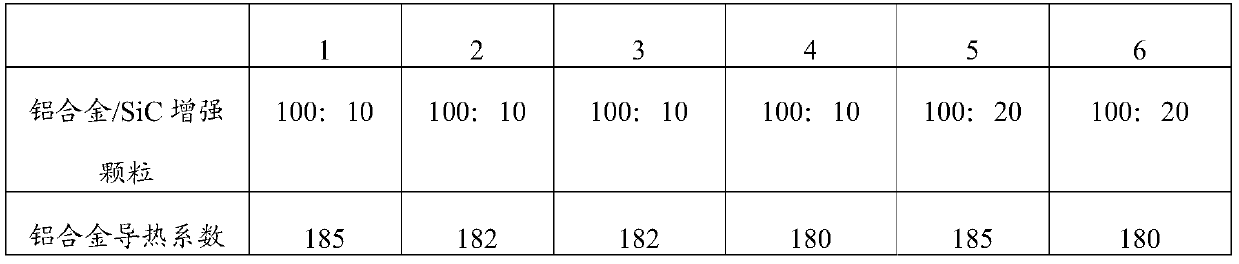

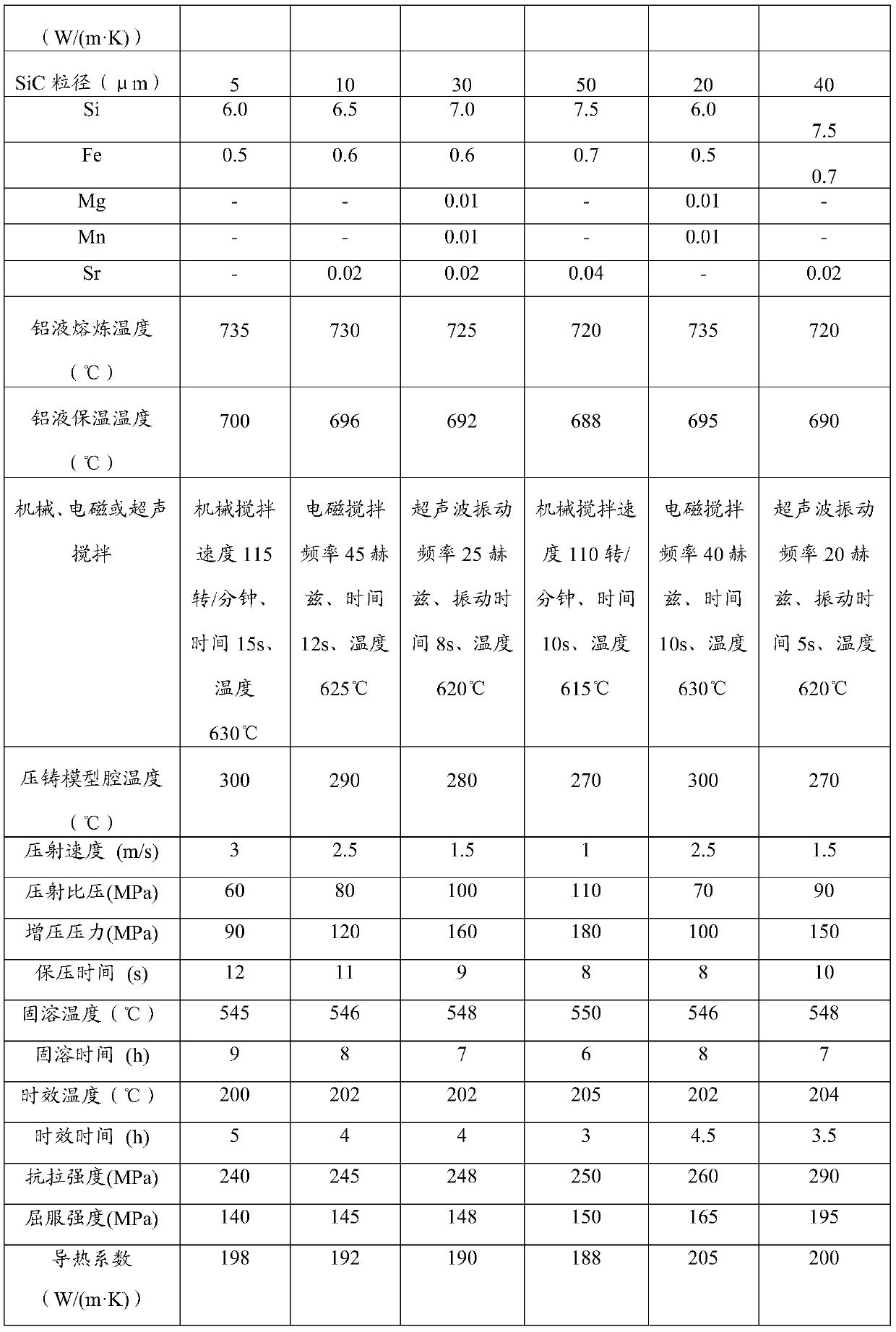

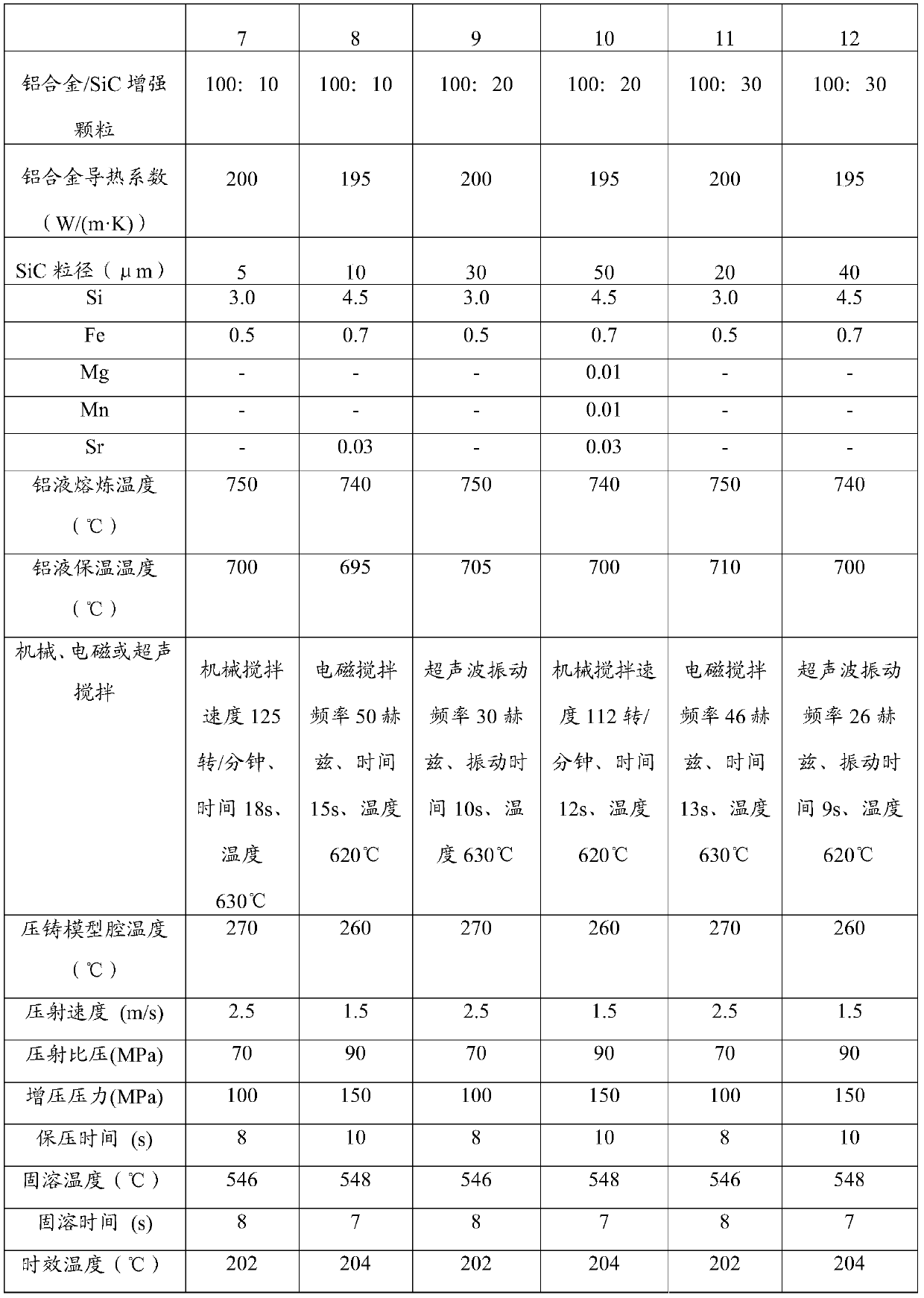

High-thermal-conductivity particle reinforcement Al-based composite and preparing method thereof

The invention relates to the technical field of metal-based composites and particularly relates to a high-thermal-conductivity particle reinforcement Al-based composite and a preparing method thereof.The high-thermal-conductivity particle reinforcement Al-based composite comprises reinforcing particles and aluminum alloy, wherein the reinforcing particles are uniformly distributed in an aluminumalloy base body and form great interface bonding with the base body; and the mass ratio of the aluminum alloy to the reinforcing particles is 100:(1-30). The preparing method has the advantages that the mass ratio of the aluminum alloy to the reinforcing particles is optimized, the quantity of each component in the aluminum alloy is controlled, and the thermal conductivity of the aluminum alloy and the reinforcing particles is controlled; and the obtained Al-based composite has high thermal conductivity and great comprehensive mechanical properties.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

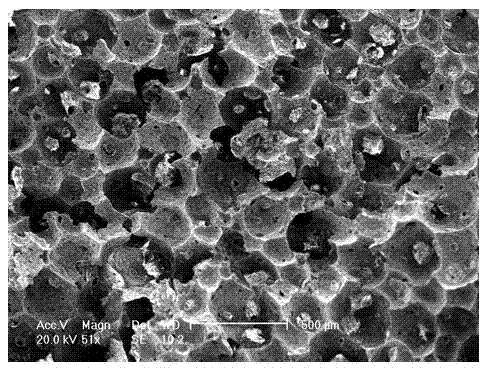

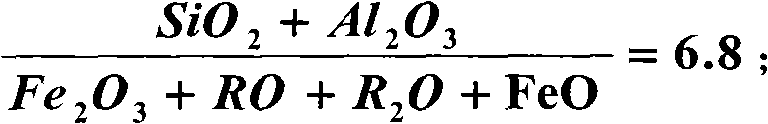

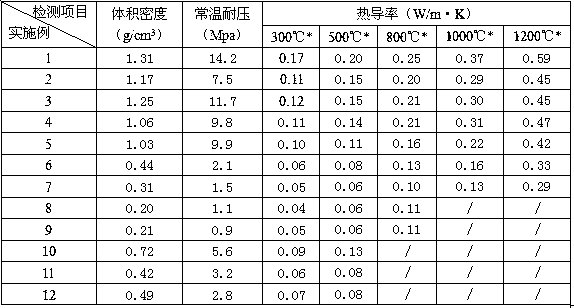

Lightweight thermal-insulting material containing silicon oxide micro powder

The invention belongs to the technical field of refractory materials and mainly relates to a lightweight thermal-insulting material containing silicon oxide micro powder. The lightweight thermal-insulting material containing the silicon oxide micro powder, provided by the invention, consists of a solid raw material and a liquid raw material; the total mass percentage of the solid raw material is 100 percent, and the solid raw material specifically consists of 1-85 percent by weight of silicon oxide micro powder, 0-80 percent by weight of gas phase white carbon black, 5-25 percent by weight of refractory fibers, 2-20 percent by weight of a foaming agent and 0.1-10 percent by weight of acid; the liquid raw material consists of a silica sol and water and occupies 40-300 percent of the total mass percentage of the solid raw material; the silica sol is an industrial-grade silica sol, and the content of silicon oxide is 28-30 percent. The lightweight thermal-insulting material provided by the invention has the benefits that the purpose of controlling the material thermal conductivity is achieved; the service life of equipment is prolonged.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

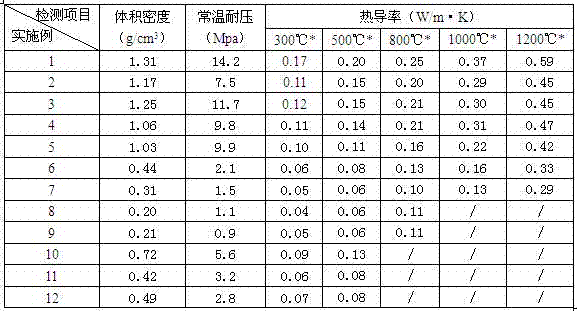

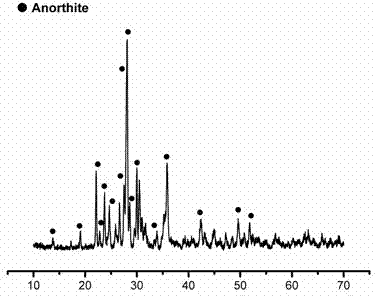

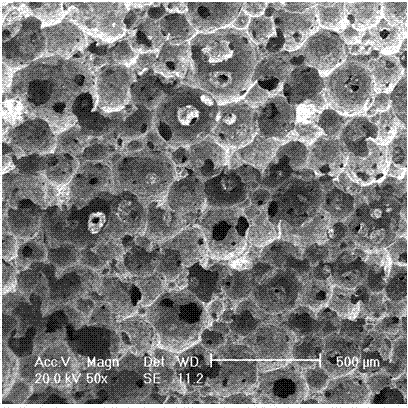

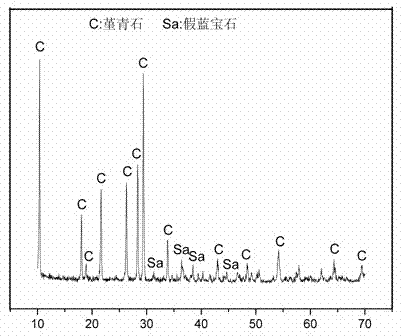

Preparation method of lightweight anorthite based thermal insulation material

InactiveCN103936407ALow thermal conductivityImprove thermal stabilityCeramicwareThermal insulationHeat stability

The invention discloses a preparation method of a lightweight anorthite based thermal insulation material. The preparation method of the thermal insulation material comprises the steps of material mixing, foaming, blending, grouting, demoulding, drying and sintering. The porosity of the obtained thermal insulation material is 85-95%, the volume density is 150-380 kg / m3, the thermal conduction coefficient is 0.04-0.06 W / (m.K), and the compressive strength is 0.48-0.97 MPa, or the compressive strength is 0.53-1.13 MPa. The thermal insulation material prepared according to the invention takes anorthite as a main crystalline phase, so that the thermal insulation material has low thermal conductivity, low specific gravity, good thermal stability, creep resistance and erosion resistance. The preparation method disclosed by the invention is simple and easy to operate, low in cost, energy-saving and environmental friendly, and suitable for industrialized production; adopted raw materials are industrial wastes such as fly ash, gypsum, waste glass, and therefore, the preparation method has extremely high economic and social significances.

Owner:HEFEI KESIFU SAFETY TECH

Vacuum insulation plate core material and preparation method thereof and vacuum insulation plate

ActiveCN107588287APromote waste reuseControl thermal conductivityThermal insulationPipe protection by thermal insulationVacuum insulated panelVolumetric Mass Density

The invention provides a vacuum insulation plate core material. The vacuum insulation plate core material comprises a mineral wool plate, and the density of the mineral wool plate is 250-300 Kg / m<3>.The invention further provides a preparation method of the vacuum insulation plate core material and a vacuum insulation plate which comprises the vacuum insulation plate core material. According to the vacuum insulation plate core material, waste recycle is promoted, the production cost of the vacuum insulation plate core material is remarkably lowered, and the vacuum insulation plate core material has good fireproof performance and can be economically and effectively applied to the field of production of mobile board rooms.

Owner:BEIJING NEW BUILDING MATERIAL

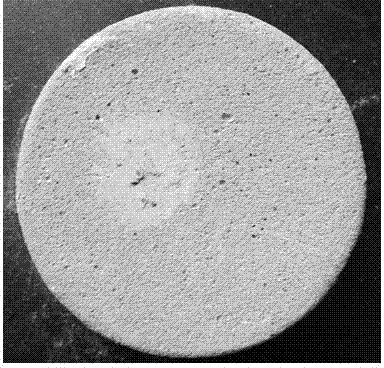

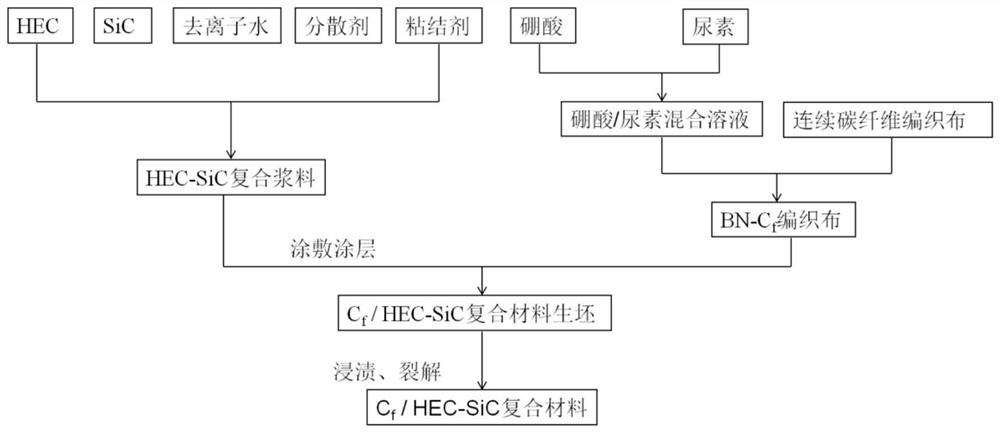

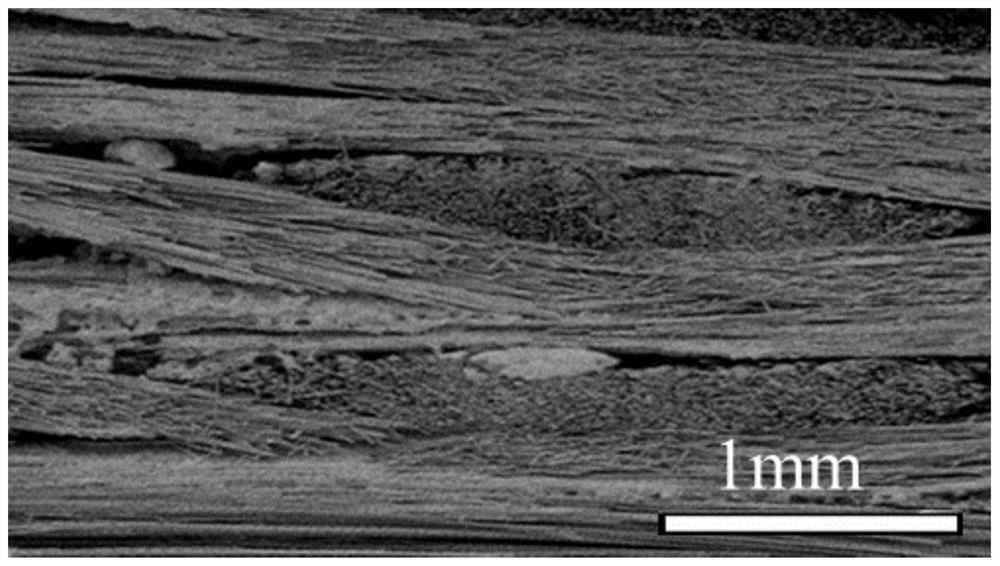

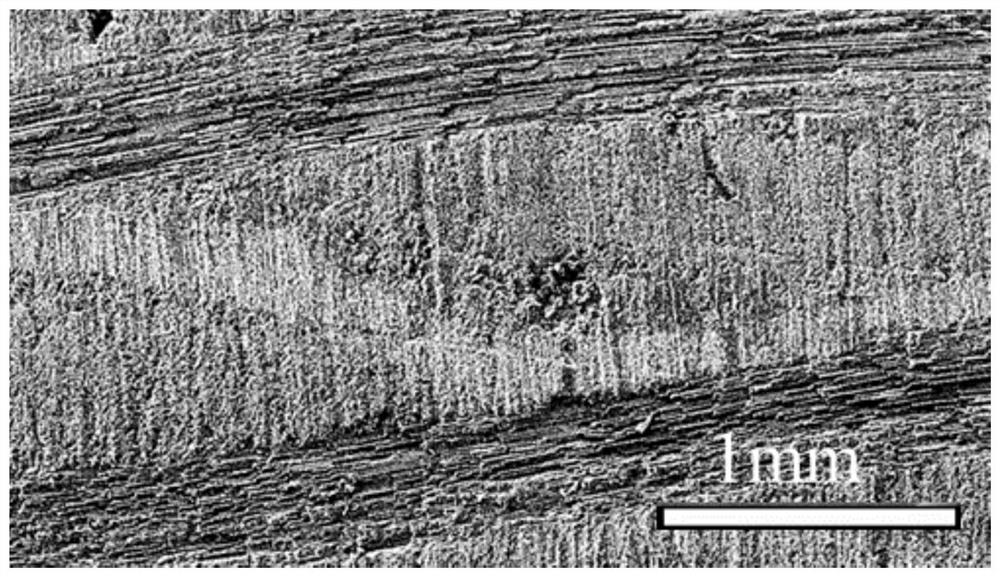

Continuous fiber reinforced high-entropy ceramic matrix composite material and preparation method thereof

ActiveCN113666765ARealize low-temperature and low-cost preparationAdjust Fiber ContentCarbon fibersSlurry

The invention discloses a continuous fiber reinforced high-entropy ceramic matrix composite material and a preparation method thereof, and belongs to the technical field of composite material forming. The preparation method of the high-entropy ceramic-based composite material comprises the following steps: carrying out primary impregnation on a carbon fiber material in a boric acid / urea mixed solution, then carrying out heat treatment to obtain a carbon fiber material with a coating, coating the carbon fiber material with the coating with composite slurry, pressurizing, drying to obtain a high-entropy ceramic-based composite material green body, and carrying out secondary impregnation and cracking on the green body in the precursor solution to obtain the high-entropy ceramic-based composite material. According to the forming method, low-temperature and low-cost preparation of the high-entropy ceramic-based composite material is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

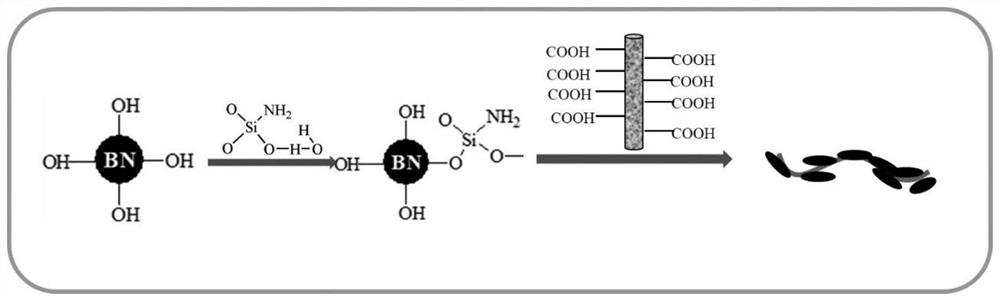

Preparation method of boron nitride/carbon nanotube/polyimide composite material

The invention relates to a preparation method of a boron nitride / carbon nanotube / polyimide composite material. The preparation method of the composite material comprises the following steps: firstly, preparing micron boron nitride into boron nitride nanosheets through a hydrothermal method, and then modifying the boron nitride nanosheets through a silane coupling agent KH550; acidizing a carbon nanotube to obtain a carboxyl carbon nanotube, compounding the modified boron nitride and the carboxyl carbon nanotube in a solvent, and adding a tetracarboxylic dianhydride monomer of diamine into a system to prepare polyamide acid, and finally, drying the polyamide acid solution added with the boron nitride / carbon nanotube composite filler, and performing high-temperature dehydration imidization to obtain the boron nitride / carbon nanotube / polyimide composite material. The microstructure of the filler particles is regulated and controlled by regulating and controlling the proportion of the boron nitride and the carbon nanotubes at the same time, so that the heat-conducting property of the composite material is regulated and controlled, the heat conductivity of the prepared composite material is larger than 0.6 W / mK, and the resistivity is larger than 1 * 10 < 11 > omegam.

Owner:大同共聚西安科技有限公司

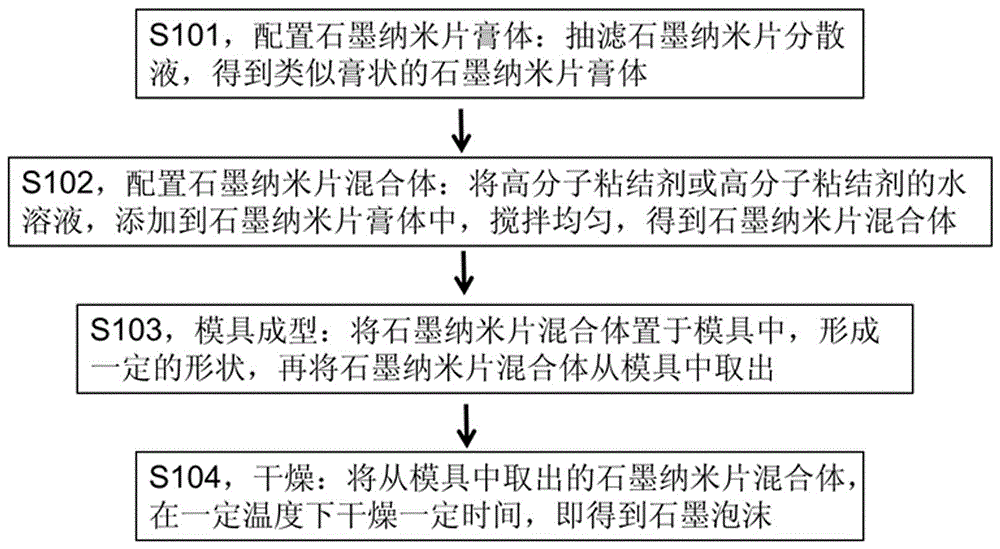

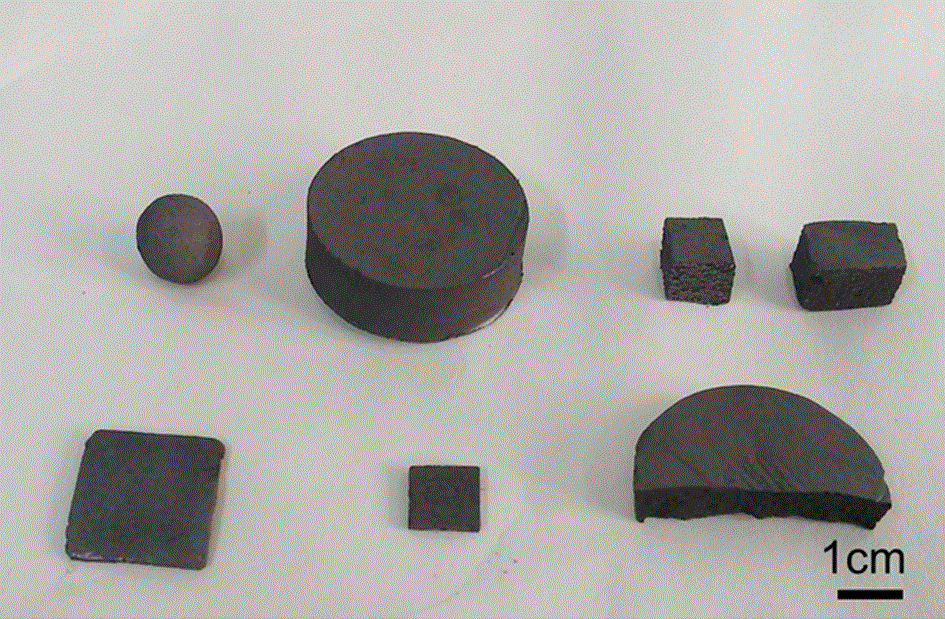

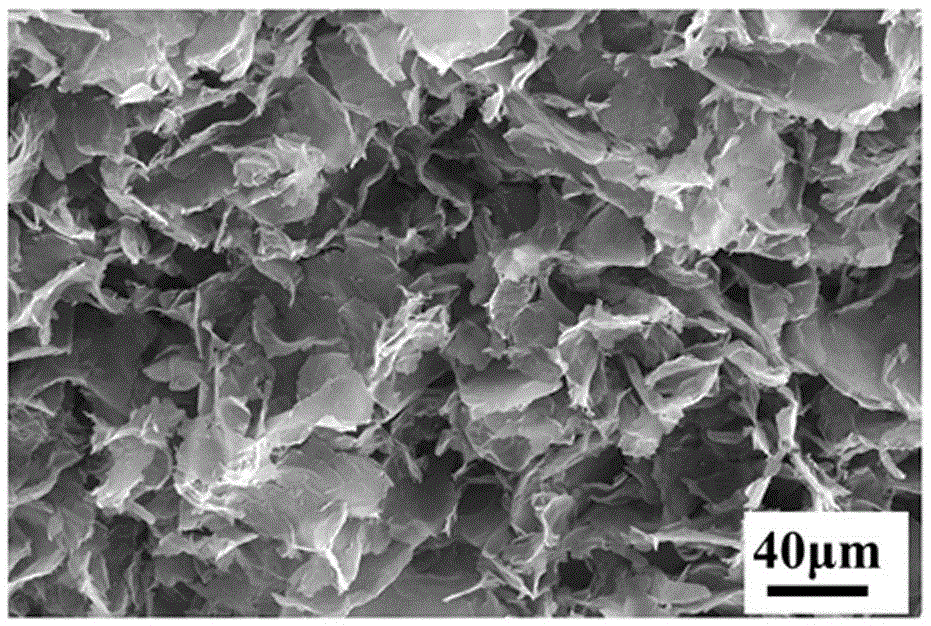

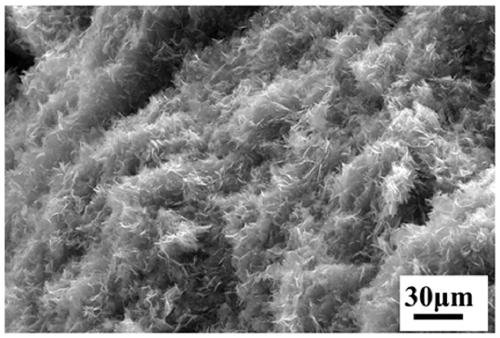

Graphite foam and preparation method thereof

ActiveCN106673700AHigh compressive strengthImprove thermal conductivityCeramic extrusion diesCeramicwareHigh pressure cellElectromagnetic shielding

The invention provides a preparation method of graphite foam. The method comprises the following steps that graphite nanosheets are used as raw materials; a small number of macromolecular bonding agents are added; through template forming, the graphite foam is formed after the drying. The preparation method provided by the invention is simple and convenient, and can be used for forming graphite foam in various shapes; in addition, the prepared graphite foam has the controllable density and uniform pores. The prepared graphite foam also has the advantages of high pressure-resistant intensity, low resistance, oil absorbability, high heat conductivity and the like, can be widely applied to the fields of heat radiators, heat conduction pads, electromagnetic shielding materials and the like, and has wide application prospects.

Owner:HARBIN INST OF TECH AT WEIHAI

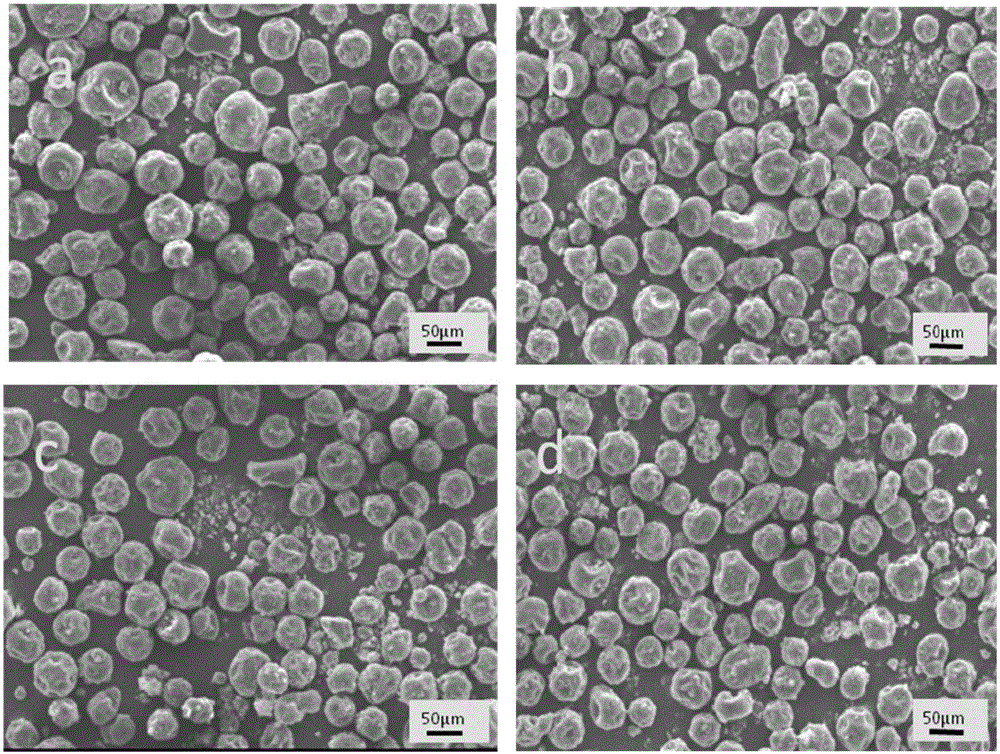

Preparation method of polystyrene ultrafine powder by use of acryloyl chloride-phenethylene copolymer azide modified carbon nano tube as antistatic agent

A preparation method of polystyrene ultrafine powder by use of acryloyl chloride-phenethylene copolymer azide modified carbon nano tube as an antistatic agent belongs to the field of heat-conducting antistatic modified engineering plastics. The preparation method comprises the following steps: preparing an acryloyl chloride-phenethylene copolymer at first; then preparing an acryloyl chloride-phenethylene copolymer azide through reaction between the acyl chloride bond and sodium azide; after that, preparing a polystyrene-encapsulated modified carbon nano tube through reaction between the azide group and a carbon nano tube; finally, enabling the polystyrene-encapsulated modified carbon nano tube to participate in suspension polymerization of phenethylene to synthesize the heat-conducting antistatic polystyrene ultrafine powder. The surface of the modified carbon nano tube contains polystyrene, so that the dispersity of the carbon nano tube in a styrene monomer is enhanced. The prepared polystyrene ultrafine powder has heat-conducting and antistatic property and can be used for preparing heat-conducting antistatic 3D printing products.

Owner:河北五洲开元环保新材料有限公司

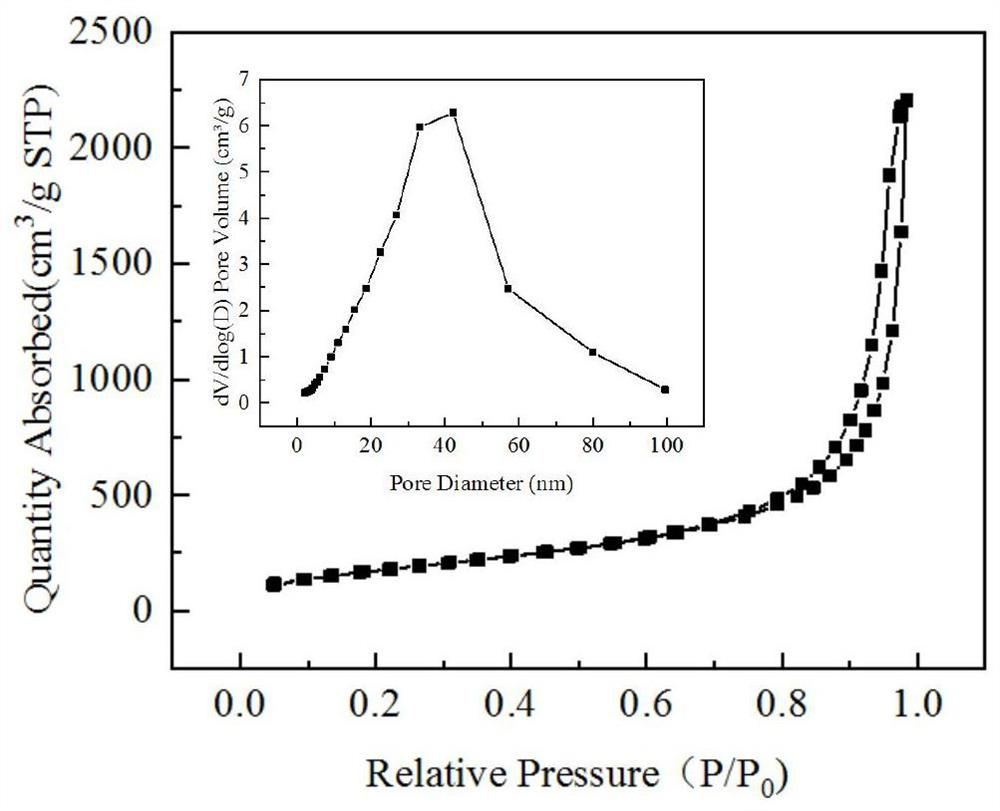

Preparation method of rare earth doped silicon dioxide aerogel

PendingCN113651334AImprove thermal conductivityControl thermal conductivitySilicon compoundsSupercritical dryingEthyl ester

The invention discloses a preparation method of rare earth doped silicon dioxide aerogel, and belongs to aerogel preparation. The preparation method comprises the following steps: sequentially adding tetraethoxysilane, ethanol and water into a container according to a ratio, mechanically stirring, adding hydrochloric acid, stirring again, sealing, standing, and carrying out a sufficient hydrolysis reaction to obtain SiO2 sol; dissolving Y (NO3) 3.4 H2O powder in water, carrying out heating reaction, cooling to room temperature to obtain a Y (NO3) 3 solution, dropwise adding the Y (NO3) 3 solution into the SiO2 sol, and uniformly stirring; dropwise adding ammonia water, and standing to obtain Y-SiO2 gel; and sealing, standing and aging, and then carrying out supercritical drying to obtain the blocky Y-SiO2 aerogel. The rare earth elements are doped into the silicon dioxide aerogel, so that the use temperature of the silicon dioxide aerogel is increased, the heat conductivity coefficient of the aerogel is reduced, and the obtained aerogel is low in density, high in specific surface area and good in heat insulation performance. The method is simple in process, high in production efficiency, low in equipment requirement and beneficial to large-scale production, and the problem that rare earth elements are non-uniformly dispersed in a silicon dioxide matrix is solved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

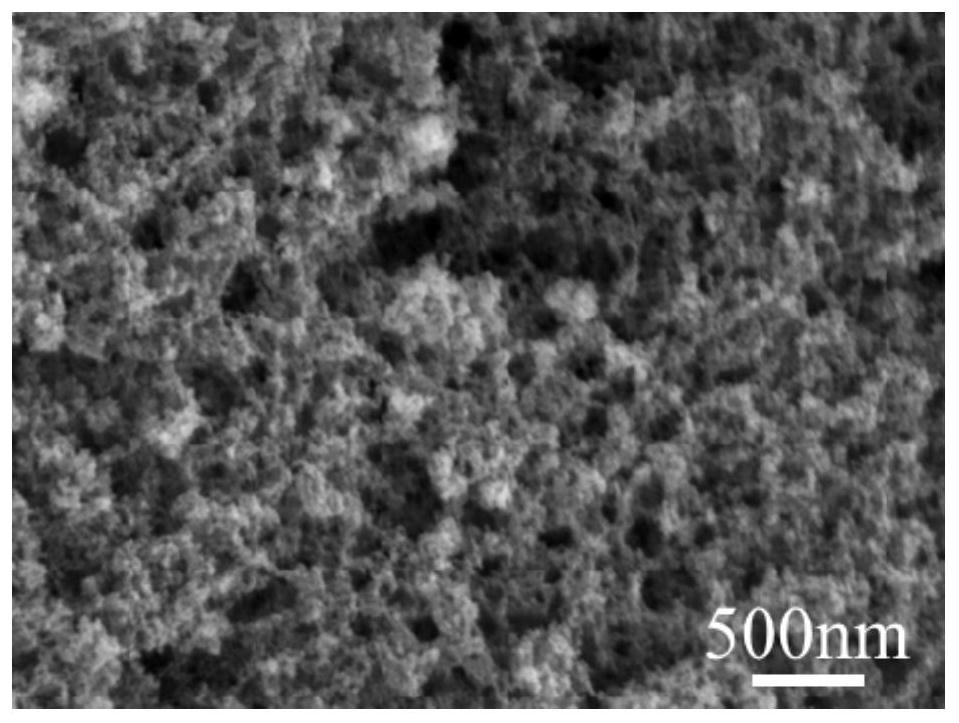

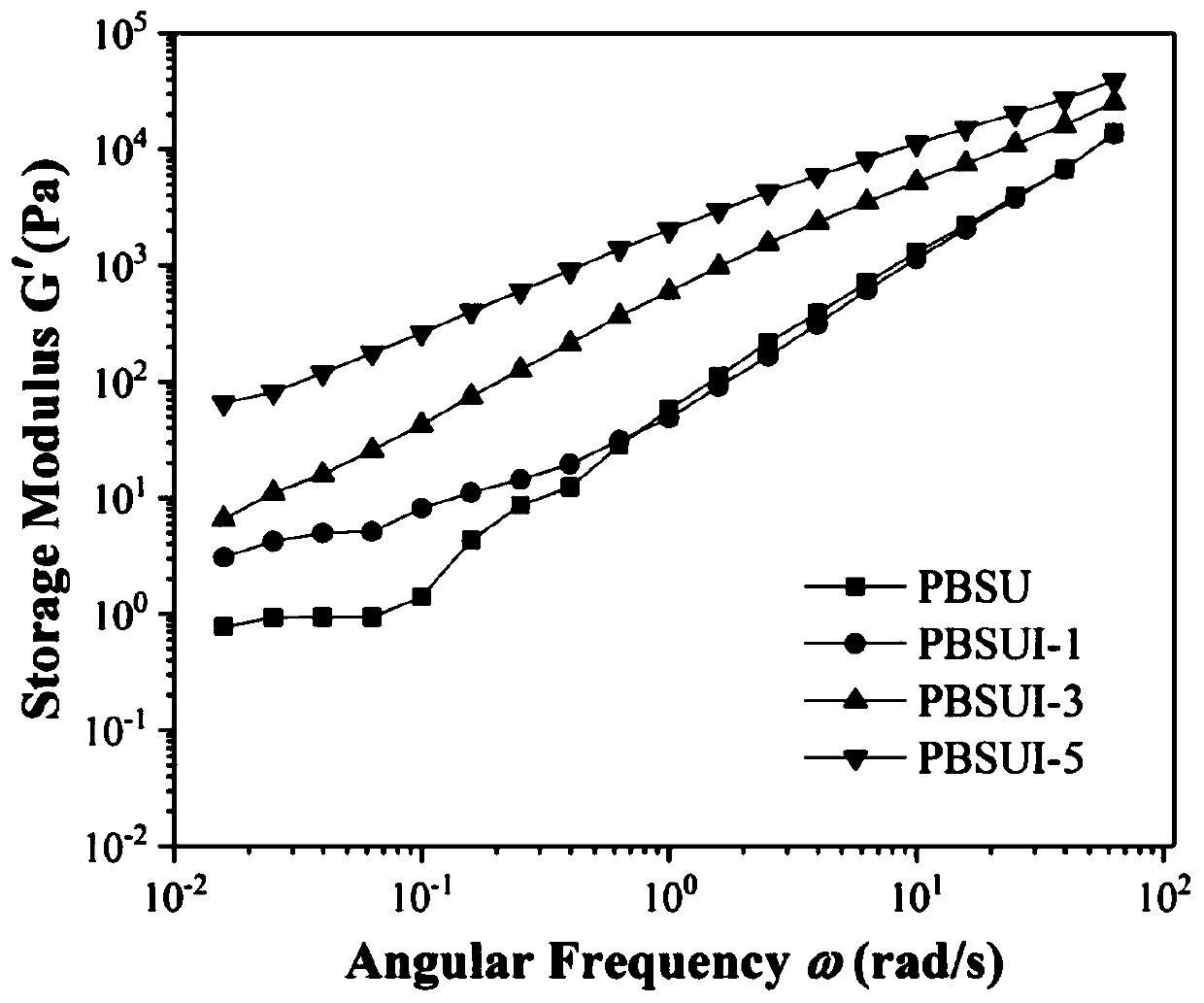

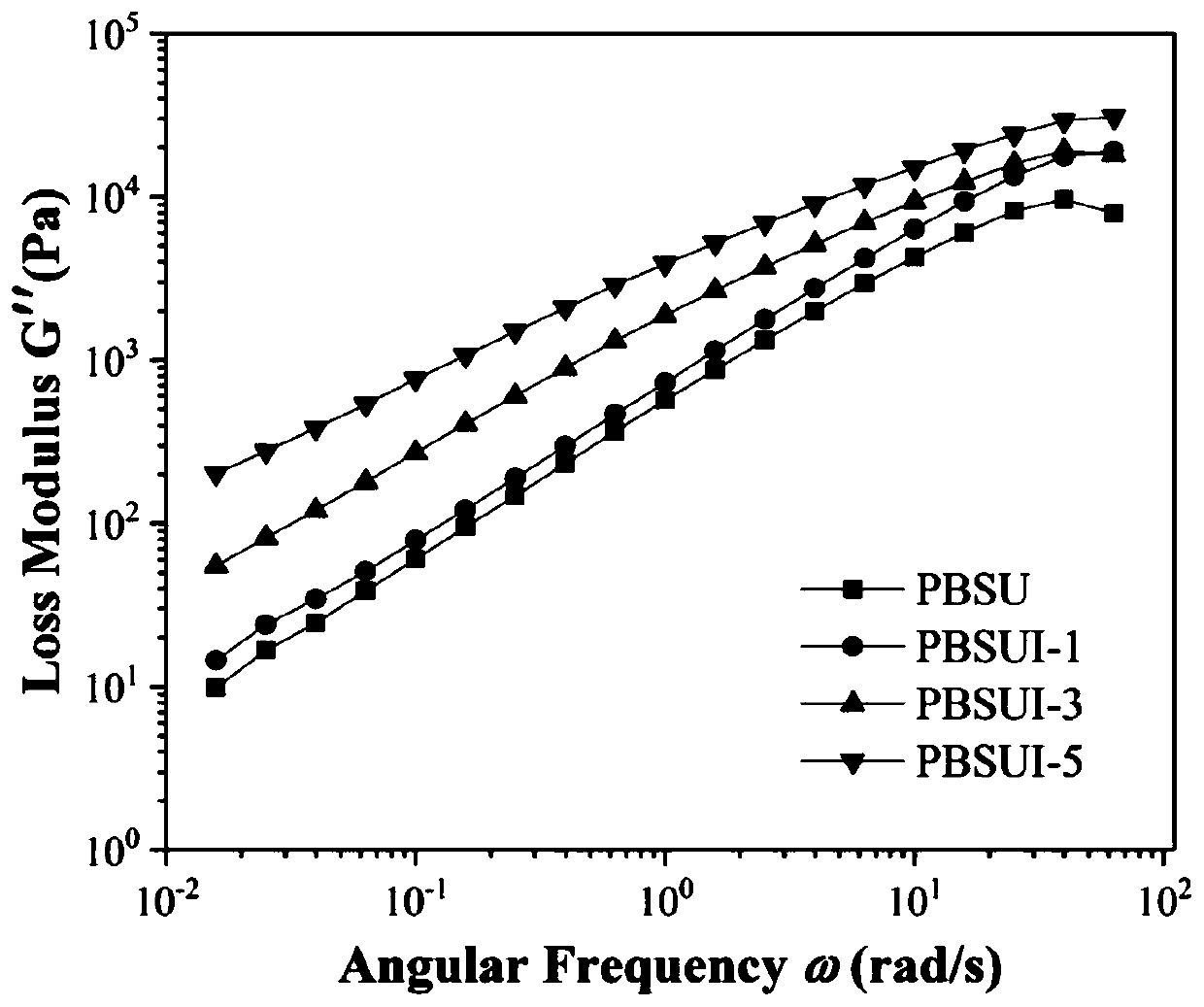

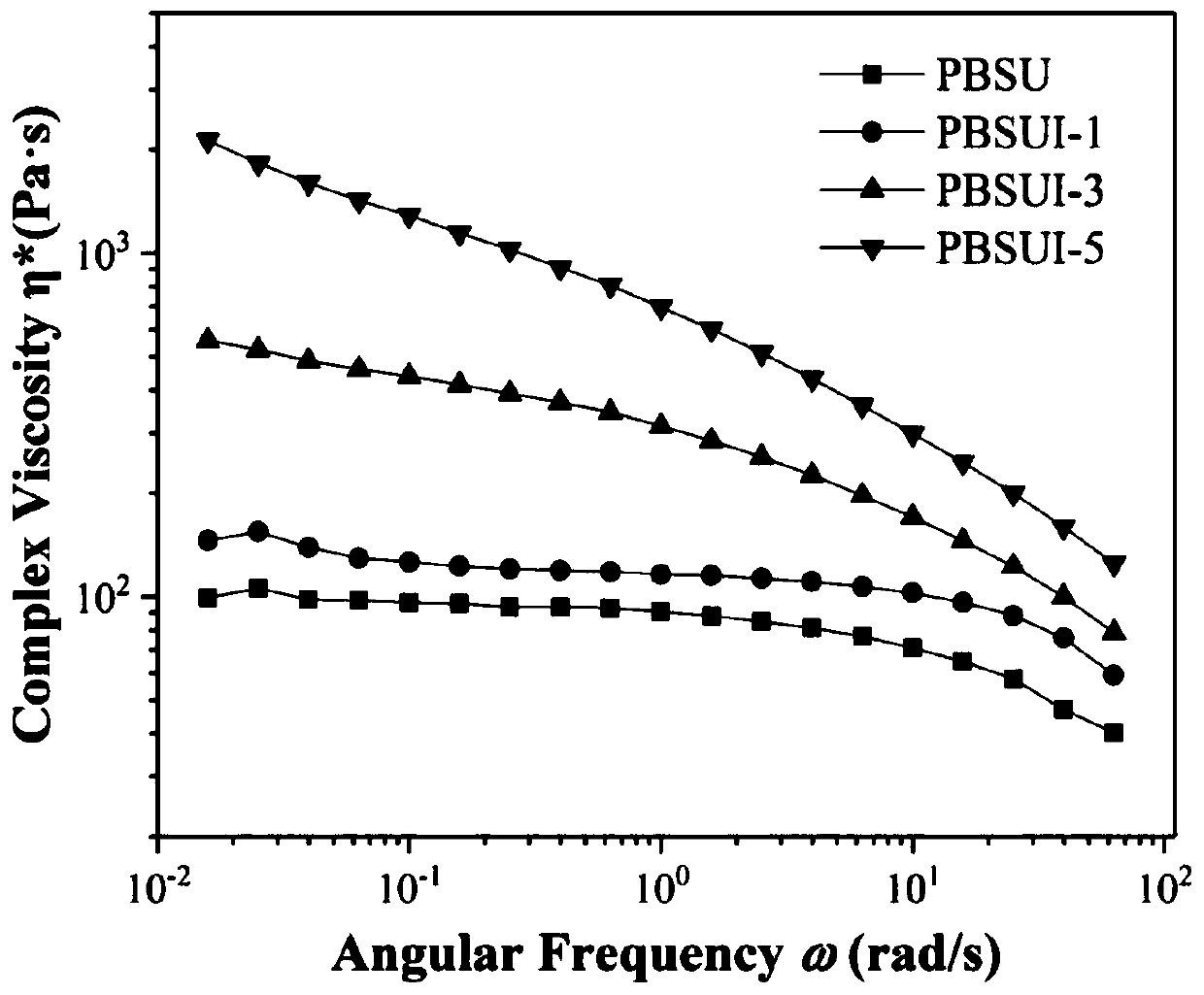

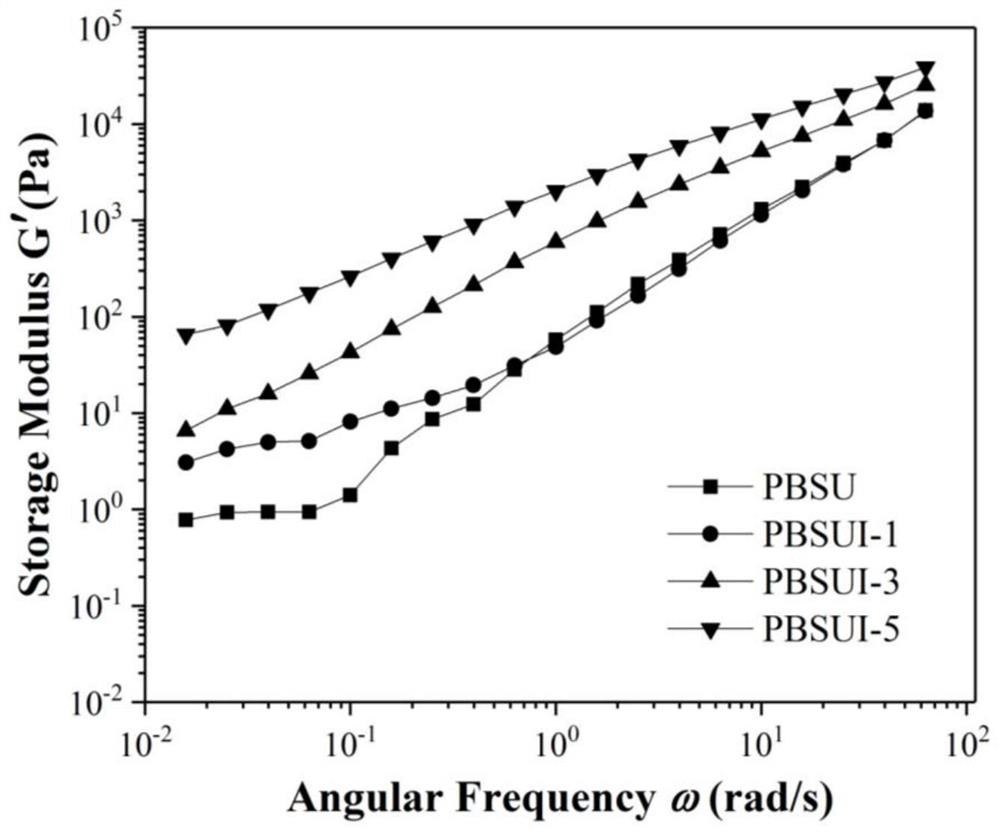

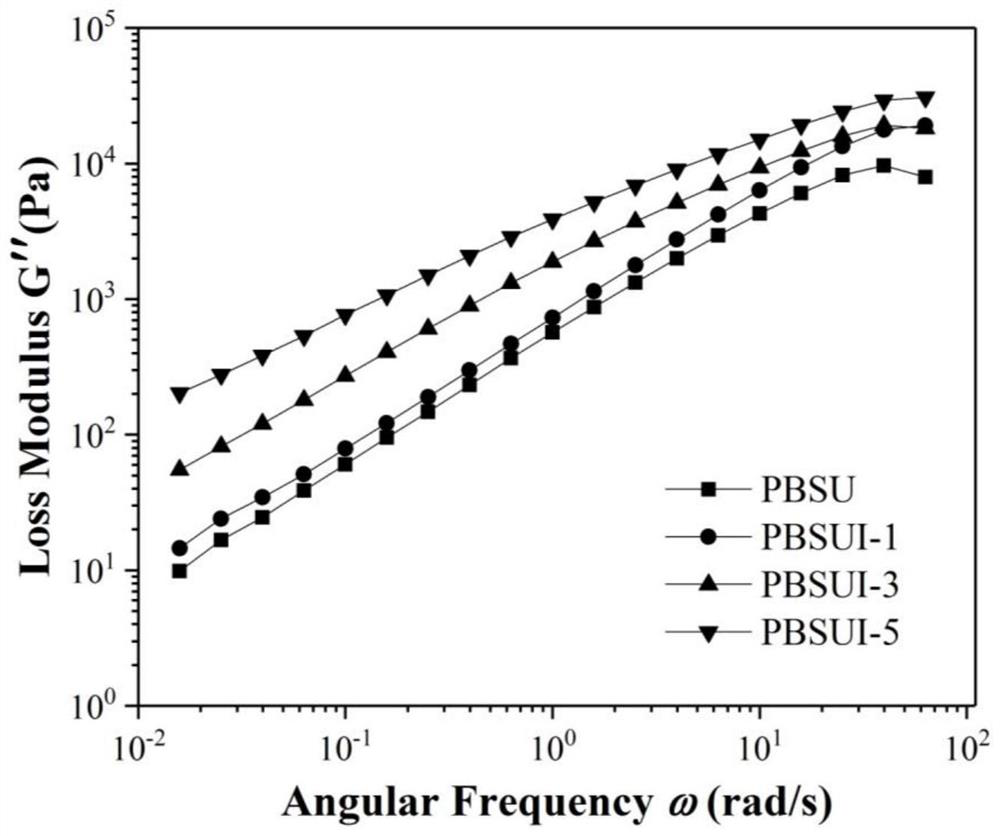

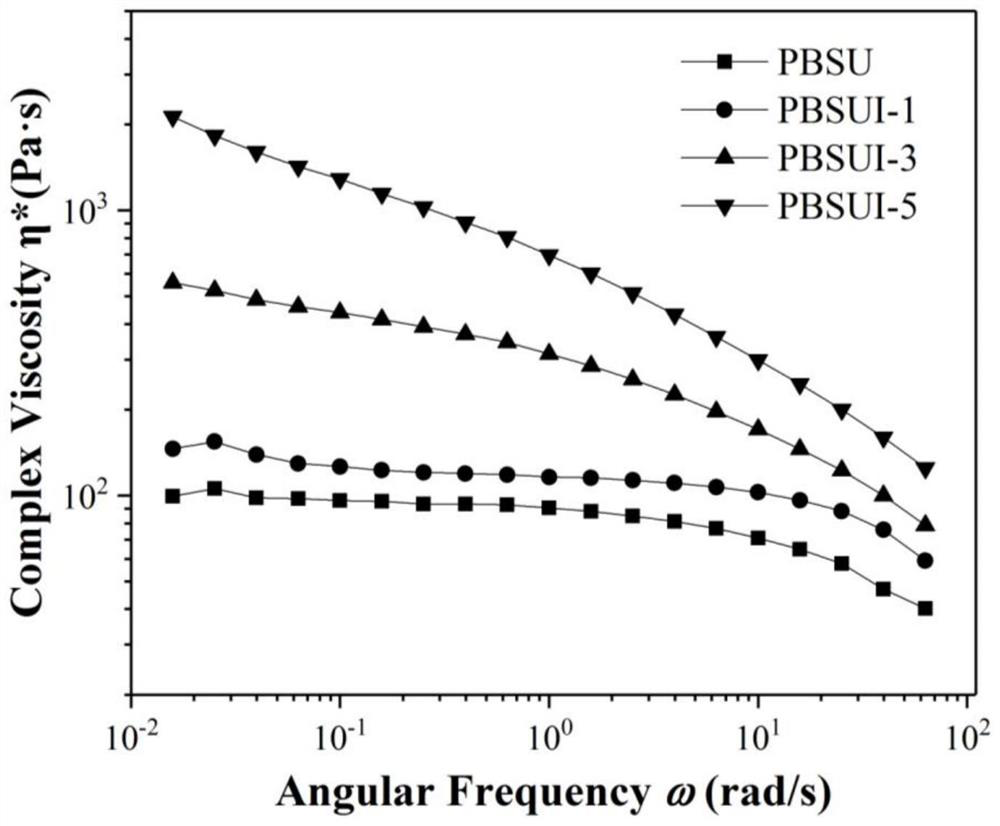

Thermally-conductive polybutylene succinate ionomer and preparation method and application thereof

The invention belongs to the technical field of polymer materials, and discloses a thermally-conductive polybutylene succinate ionomer and a preparation method and application thereof. The preparationmethod comprises the following steps that under an inert atmosphere, succinic acid and butanediol are mixed, stirred and heated for a reaction, a catalyst is added, during vacuuming, the temperatureis increased to 200-220 DEG C for a reaction of 0.5-2.5 hours, and a polybutylene succinate prepolymer is obtained; then the temperature is decreased to 135-155 DEG C, an ionic monomer is added, and vacuuming is conducted for a reaction of 1.5-3.5 hours; finally, nitrogen is introduced, a chain extender is added for a reaction, and after the reaction is completed, cooling is conducted to room temperature to obtain the thermally-conductive polybutylene succinate ionomer. The thermally-conductive polybutylene succinate ionomer is subjected to hot pressing treatment to prepare a sheet-shaped sample strip, then stretching treatment is conducted, and the anisotropic thermally-conductive polybutylene succinate ionomer is prepared.

Owner:SOUTH CHINA UNIV OF TECH

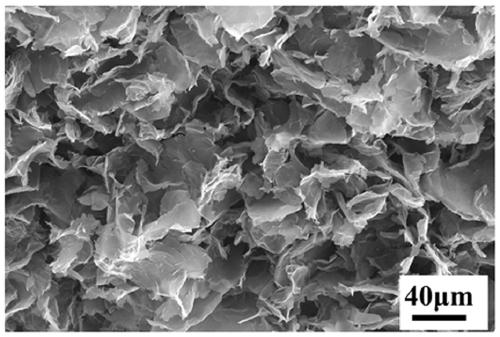

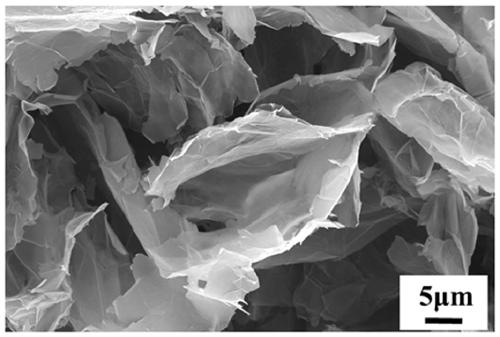

Graphene paper with adjustable porous structure

InactiveCN110482534AGood flexibilityImprove electrochemical capacitanceGrapheneFlexible electronicsCvd graphene

The invention discloses graphene paper with an adjustable porous structure. The graphene paper is prepared from a graphene gel precursor. The graphene paper has a porous structure, so that the graphene paper has excellent flexibility and huge specific surface area, and has huge potential in the field of flexible electronic devices; meanwhile, due to the porous structure, the material is very easyto compound with some functional materials, and has a wide application prospect in the fields of environmental protection, catalysis, semiconductors, flexible electronic devices, biomedical materialsand the like. The porous structure of the graphene paper can be regulated and controlled by adjusting preparation conditions, and the graphene paper can adapt to different application occasions.

Owner:安徽聚科生物科技有限公司

Preparation method of lightweight cordierite-based thermal insulation material

InactiveCN103922790ALow thermal conductivitySmall coefficient of thermal expansionCeramicwareClaywaresThermal dilatationThermal insulation

The invention relates to a preparation method of a lightweight cordierite-based thermal insulation material. The thermal insulation material is prepared by sintering the following materials in parts by weight: 43 to 64 parts of kaolin, 11 to 34 parts of attapulgite, and 22 to 29 parts of basic magnesium carbonate, or 50 to 73 parts of kaolin, 14 to 39 parts of attapulgite and 10 to 21 parts of magnesium oxide. The preparation method comprises the following steps: mixing the materials; foaming; grouting; demoulding and drying; sintering. The porosity of the obtained lightweight cordierite-based thermal insulation material ranges from 83% to 90%; the volume density of the thermal insulation material ranges from 270kg / m<3> to 400kg / m<3>; the thermal conductivity coefficient of the thermal insulation material ranges from 0.07W / (m.K) to 0.09W / (m.K); the compressive strength of the thermal insulation material ranges from 0.53MPa to 1.13MPa. The prepared thermal insulation material taking cordierite as a principal crystalline phase is low in thermal conductivity, low in specific gravity, low in thermal expansion coefficient, good in thermal stability and resistant to creep deformation and erosion. The preparation process is simple, easy to operate and low in cost, is energy-saving and environment-friendly, and is suitable for industrial production.

Owner:HEFEI KESIFU SAFETY TECH

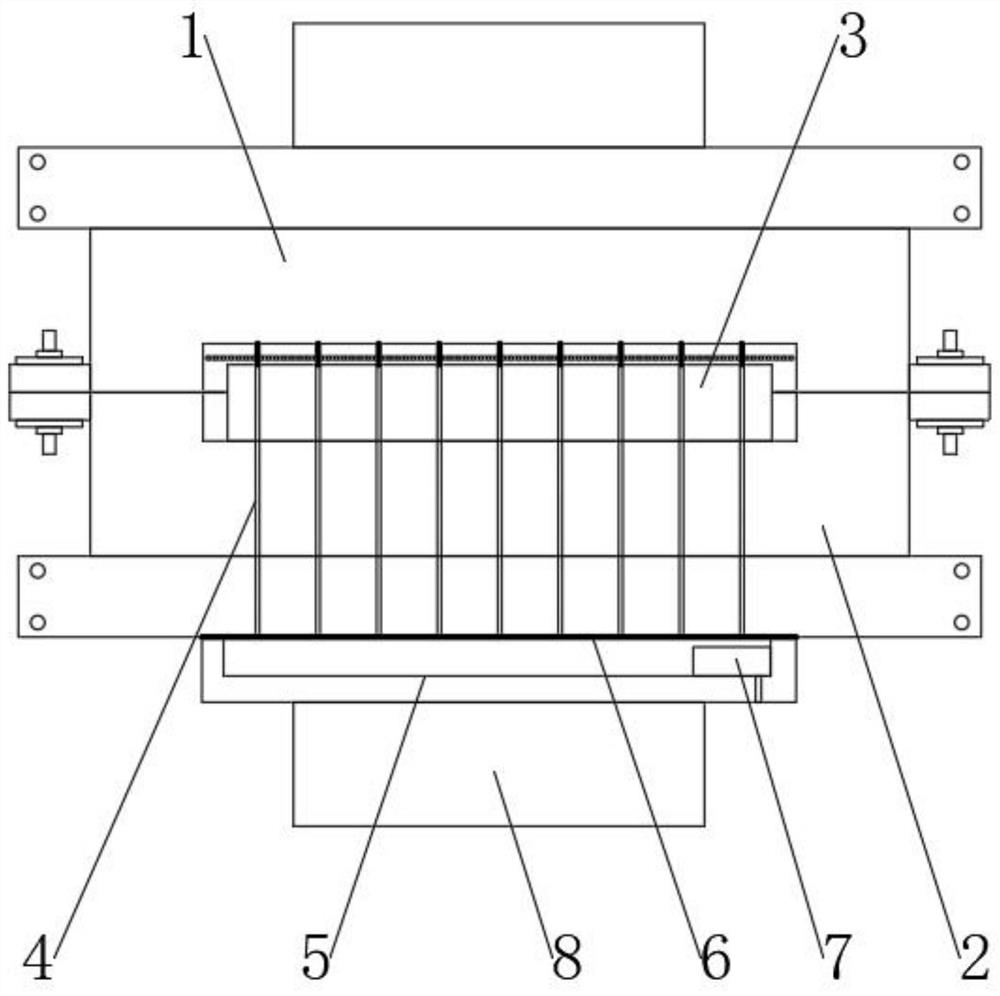

Router upper and lower cover injection mold and injection molding process thereof

InactiveCN112622184AImprove thermal stabilityDistribute quicklyDomestic articlesTemperature controlHeat stability

The invention discloses a router upper and lower cover injection mold and an injection molding process thereof, and belongs to the technical field of injection molding. By means of the router upper and lower cover injection mold, prepared pore-forming balls can be injected into a raw material through temperature control columns in a micro-curing state of the raw material in the manner of positioning and mounting the plurality of temperature control columns in the mold, filling in the raw material is carried out to form a similar interlayer, temperature control balls are then controlled to be distributed on the surface of the raw material through the magnetic attraction effect, finally, the pore-forming balls are sucked out to form a cavity in the raw material to serve as a heat preservation interlayer, the temperature control balls are at the surface to serve as a heat conduction layer, and heat conduction variable bags in the temperature control columns make contact with a composite heat conduction plate in the high-temperature state, so that working heat of electron components in a router shell can be quickly dissipated, in a low-temperature state, temperature sensing control rods in the heat conduction variable bags contract when meeting cold, the heat conduction variable bags are separated from the composite heat conduction plate, external cold is difficult to enter the shell, heat preservation is carried out by virtue of heat generated by the temperature sensing control rods, and the working thermal stability of a router is improved.

Owner:苏州祥盈升精密实业有限公司

Improved automobile friction material

InactiveCN104845585AControl the coefficient of thermal expansionControl thermal conductivityOther chemical processesFriction liningFiberThermal dilatation

The invention provides an improved automobile friction material. The improved automobile friction material is prepared from the following raw materials in parts by weight: 3-5 parts of polypropylene ester, 2-4 parts of a dispersant, 6-9 parts of modified polypropylene, 4-6 parts of hydroquinone, 5-8 parts of a friction performance conditioning agent, 9-18 parts of mica powder, 6-10 parts of graphite powder, 4-9 parts of high-strength carbon fibers, 11-16 parts of hollow glass micro-beads, 2-6 parts of glass fibers, 5-10 parts of an anti-rusting agent and 3-6 parts of polyamide. The improved automobile friction material provided by the invention has the beneficial effects that the thermal dilatation coefficient, the thermal conductivity and the shrinking percentage of a product can be effectively controlled, the stability of the product size is increased, the friction performance is good and the production cost is low.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

Haydite used as conductive concrete aggregate and preparation thereof

Owner:WUHAN UNIV OF TECH

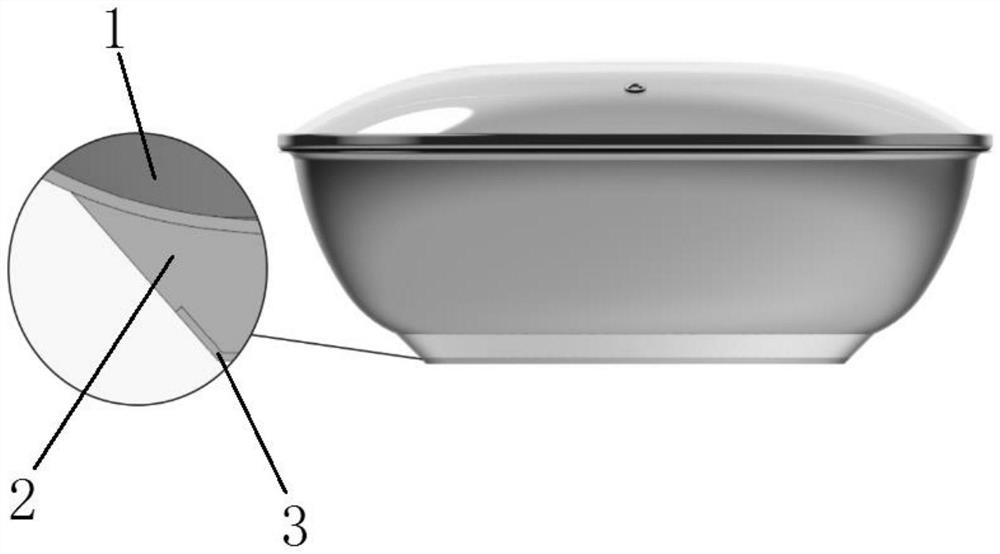

Novel light energy storage constant-temperature pot

The invention provides a novel light energy storage constant-temperature pot which comprises a pot body and a pot bottom and further comprises a foam metal heat preservation layer and an inorganic ceramic heat insulation layer, the foam metal heat preservation layer is fixedly installed between the pot body and the pot bottom, and the inorganic ceramic heat insulation layer is laid on the inner surface and / or the outer surface of the pot body and / or the pot bottom. The heat preservation and heat insulation performance of the pot body can be achieved, the overall weight of the constant-temperature pot can be reduced, the constant-temperature pot can be used on heat sources such as an induction cooker, a gas open fire and a hot ceramic stove, user operation is facilitated, the temperature in the pot is kept within a certain range in the cooking and heating process, the taste and delicious taste of fresh food are reserved, and the safety of nutritional ingredients of the food is also guaranteed.

Owner:GUANGDONG DELUXE METAL PROD CO LTD

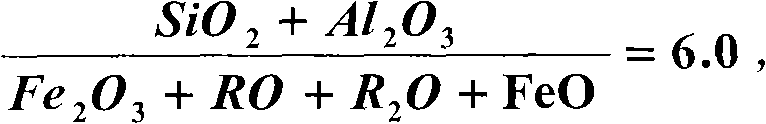

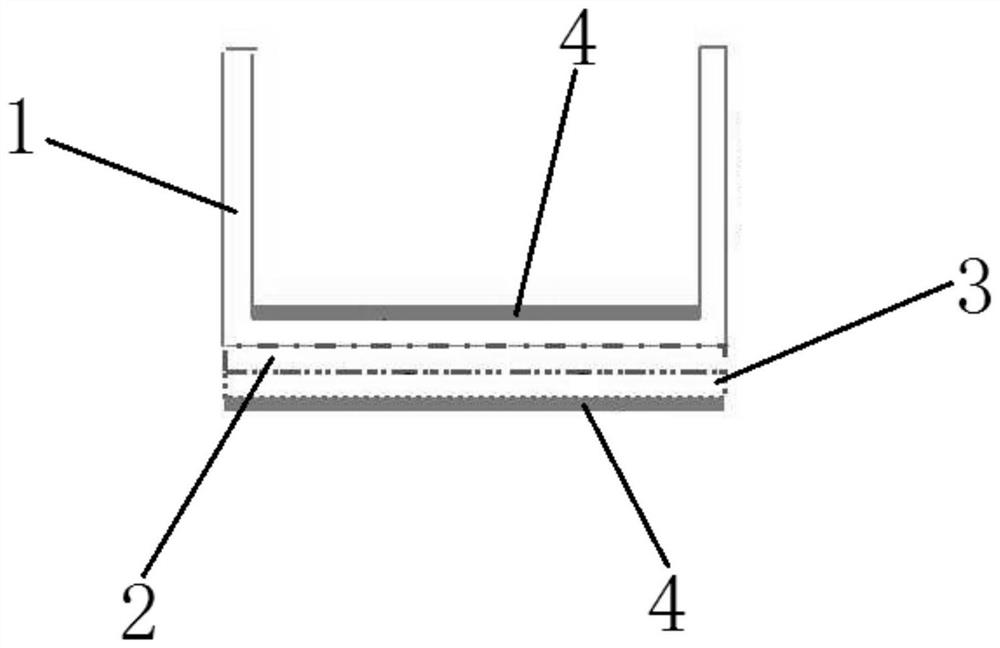

Graphite-silicone rubber composite material and preparation method thereof

InactiveCN113147116AControl thermal conductivityLamination ancillary operationsSpecial paperGraphiteSilicon rubber

The invention relates to a graphite-silicone rubber composite material and a preparation method thereof. The preparation method comprises the following steps: selecting graphite paper as a matrix; placing the substrate in alkaline oil removal water at 55-75 DEG C for ultrasonic oscillation, and using distilled water for cleaning after ultrasonic oscillation is completed; preparing a KH-550 solution with the mass fraction concentration of 5-20% by using absolute ethyl alcohol or acetone as a solvent; putting the cleaned graphite paper into a prepared KH-550 solution to be soaked, and then taking the graphite paper out and drying; placing a layer of spread graphite paper; spraying a layer of methyl vinyl silicone rubber with uniform thickness on the upper surface of the graphite paper by using a spraying machine; placing a layer of spread graphite paper on the upper surface of the methyl vinyl silicone rubber; repeating the steps; applying continuous constant pressure, and completely curing the material after preset time; and shearing along a direction perpendicular to the spreading direction of the graphite paper to obtain the formed graphite-silicone rubber composite material. According to the method, the graphite-silicone rubber composite material with uniform thickness and high bonding strength can be obtained.

Owner:SHANGHAI UNIV

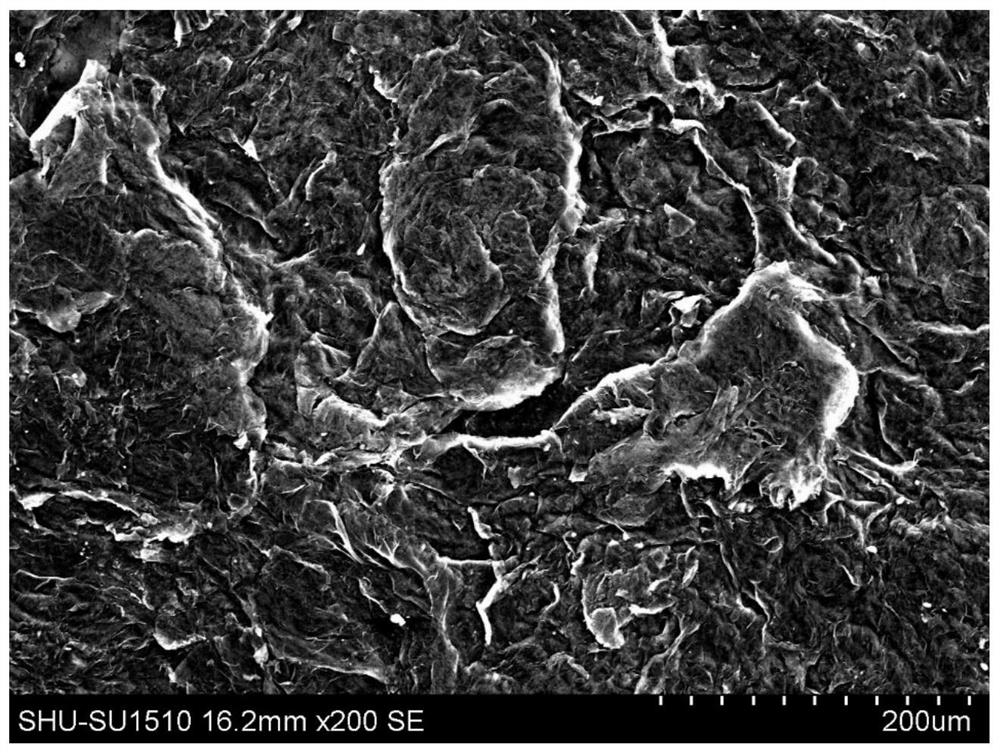

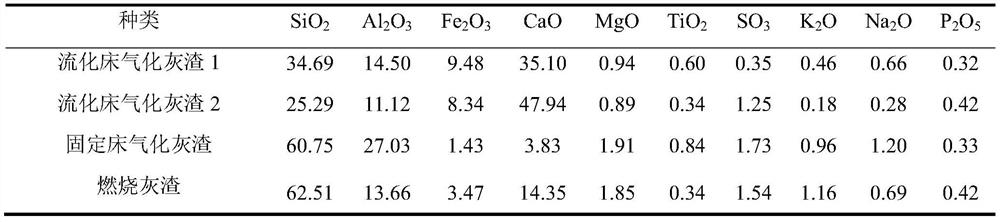

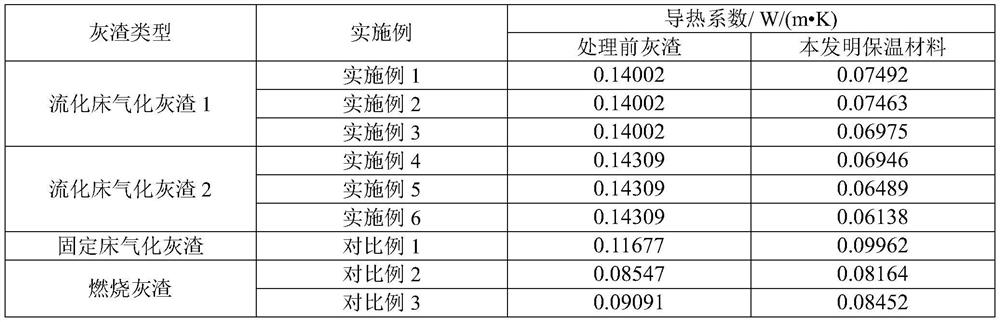

A method for preparing low thermal conductivity thermal insulation material from high-calcium gasification ash slag

ActiveCN108033697BWide variety of sourcesAchieve the purpose of usingOther chemical processesCement productionThermal insulationEthylic acid

A method for preparing a low-conductivity-coefficient heat preservation material by using high-calcium gasified ash comprises the steps that high-calcium gasified ash is burned at the temperature of 600-800 DEG C for 1-3 hours after being smashed, the decarbonized ash is obtained after quenching is conducted, the decarbonized ash serves as a reaction raw material, a acetic acid with the molar concentration being 2-9 M is taken to be mixed with the reaction raw material at the ratio of the acetic acid to the reaction raw material being 60-150 ml:10g, and the reaction is conducted at the temperature of 50-90 DEG C for 30-180 minutes; the ash subjected to acetic acid treatment is filtered, the filter residue is washed to be neutral, then dried, smashed, and sieved, and the low-conductivity-coefficient heat preservation material is obtained. The method has the characteristics of being low in the conductivity coefficient and simple to prepare.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

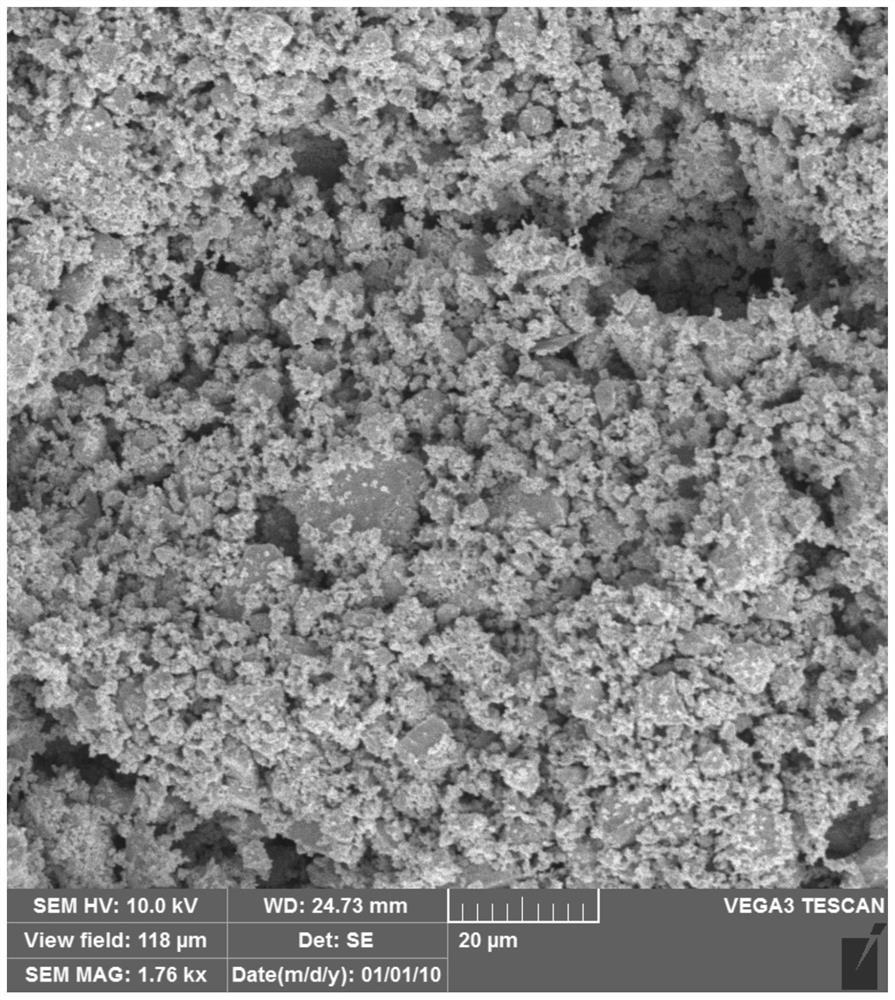

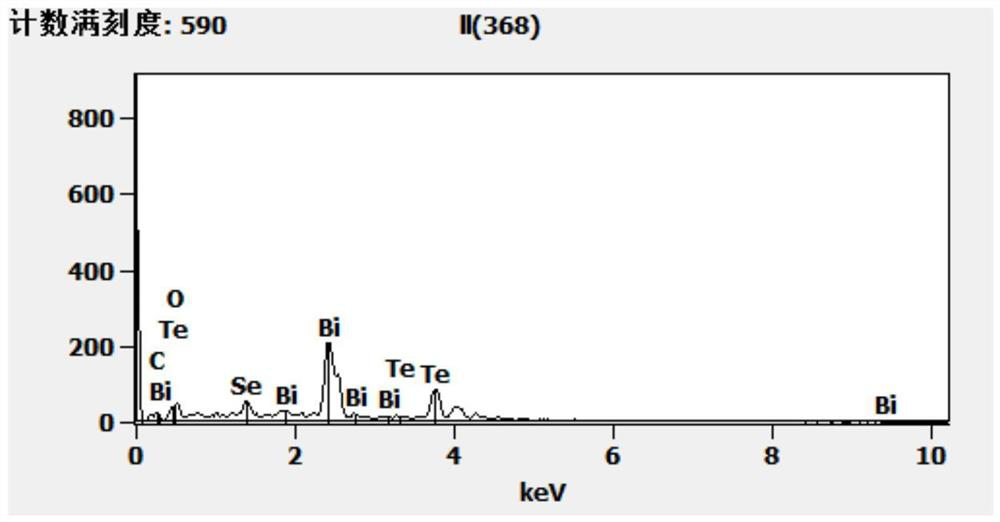

A kind of preparation method of thermoelectric power generation material

ActiveCN113121235BImprove thermoelectric conversion efficiencyHigh mechanical strengthThermoelectric device manufacture/treatmentThermoelectric device junction materialsBismuth tellurideEngineering physics

Owner:HARBIN INST OF TECH

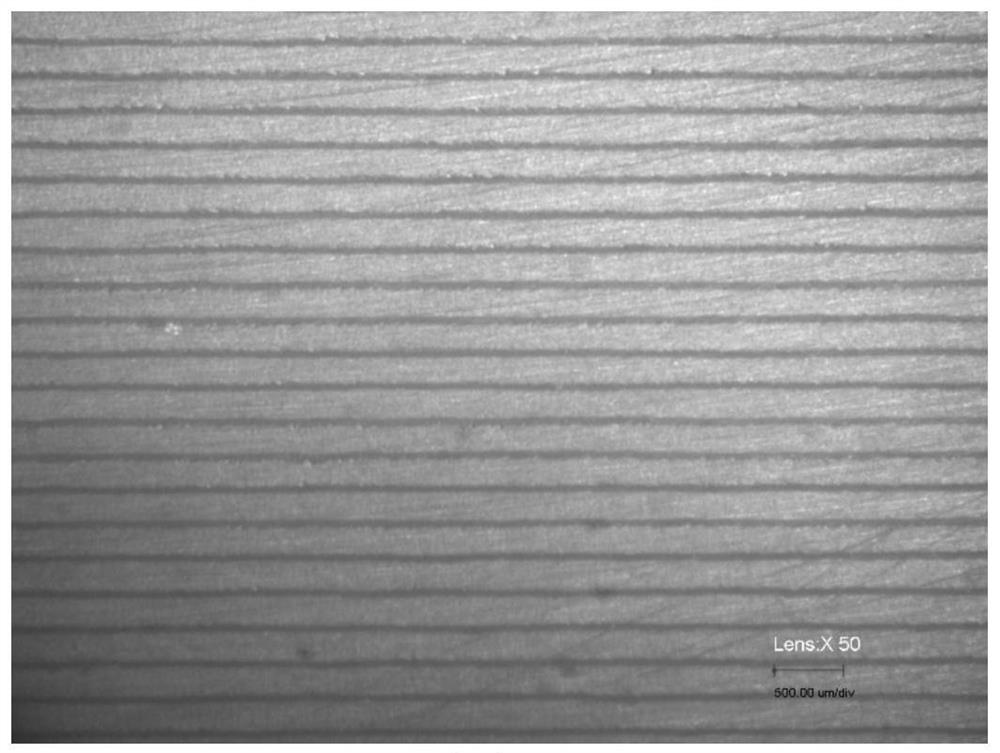

Graphite-silicone rubber composite material and preparation method thereof

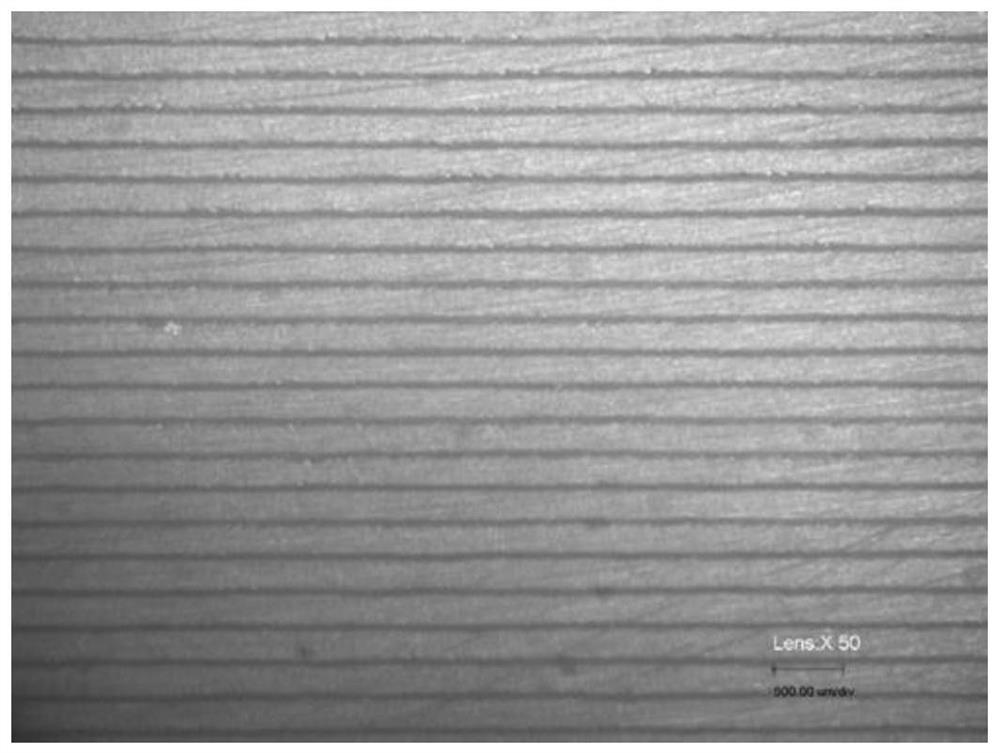

ActiveCN113696560AControl thermal conductivityLamination ancillary operationsSpecial paperGraphiteSilicon rubber

The invention relates to a graphite-silicone rubber composite material and a preparation method thereof. The preparation method comprises the following steps: selecting graphite paper as a matrix; performing ultrasonic oscillation on the substrate in alkaline oil removal water at 55-75 DEG C, and cleaning the substrate in distilled water; preparing a KH-550 solution with the mass fraction concentration of 5-20% by using absolute ethyl alcohol or acetone as a solvent; soaking the cleaned graphite paper in a prepared KH-550 solution, and then taking out and drying the graphite paper; placing a layer of spread graphite paper; spraying a layer of methyl vinyl silicone rubber with uniform thickness on the upper surface of the graphite paper by using a spraying machine; placing a layer of spread graphite paper on the upper surface of the methyl vinyl silicone rubber; repeating the steps; applying continuous constant pressure to completely cure the material after preset time; and shearing the graphite paper along a direction perpendicular to the spreading direction to obtain the formed graphite-silicone rubber composite material. According to the method, the graphite-silicone rubber composite material with uniform thickness and high bonding strength can be obtained.

Owner:上海六晶科技股份有限公司 +1

A kind of brake friction lining material with high stable friction coefficient and preparation method thereof

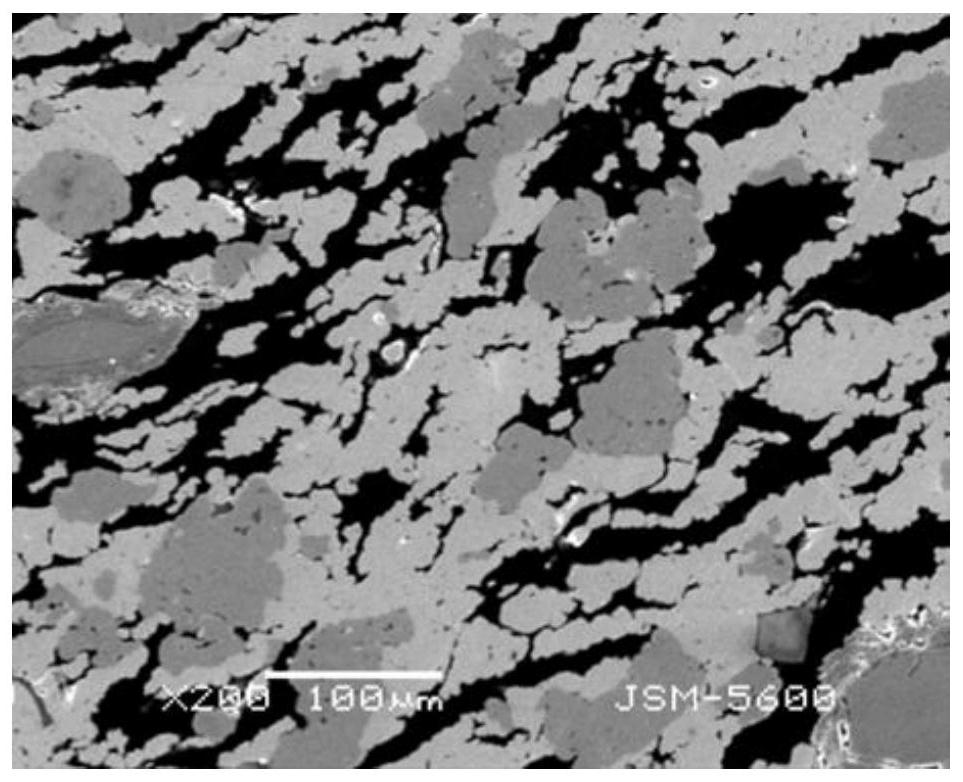

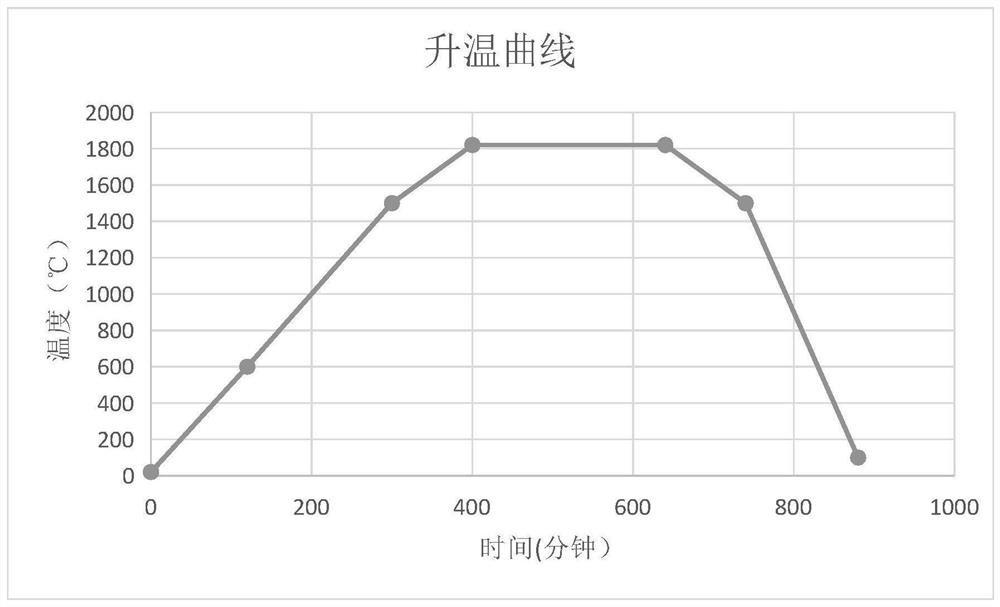

ActiveCN109079133BLow densityReduce porosityTurbinesOther manufacturing equipments/toolsBrakeShielding gas

The invention discloses a brake friction plate with a high stable friction coefficient. The brake friction plate material comprises copper-based metallurgical powder and is prepared from, by weight, 10.0-10.5% of graphite, 0.6-1.0% Cr, 18.5-20.3% of Fe 4.3-5.8% of Sn, 1.5-2.5% of TiO2, 1-2% of SiO2 and the balance Cu. The invention discloses a preparation method of the brake friction plate with the high stable friction coefficient, the copper-based metallurgical powder used for preparing the brake friction plate is mixed in proportion and then subjected to cold pressing, the pressure intensityis 560 MPa, the compression speed is 170 mm / min, the powder is formed at 560 MPa and then kept at 3 min, sintering is conducted under the dissociated ammonia shielding gas condition, the sintering temperature is 1,120 DEG C, and the sintering time is 40 min.

Owner:CHANGCHUN UNIV OF TECH

A kind of graphite foam and preparation method thereof

ActiveCN106673700BEasy to prepareSimple methodCeramic extrusion diesCeramicwareElectrical resistance and conductanceElectromagnetic shielding

Owner:HARBIN INST OF TECH AT WEIHAI

Sintering method of aluminum nitride ceramic substrate

A method for sintering an aluminum nitride ceramic substrate. During the sintering process of the substrate, an inert gas is used to replace the atmosphere in the hearth of a graphite sintering furnace. The sintering method of the present invention adopts a controllable nitrogen protection atmosphere and periodically replaces the atmosphere in the furnace , adjust the furnace pressure of the graphite sintering furnace and the atmosphere of chemical substances in the furnace, discharge the impurity atmosphere, control the thermal conductivity of the aluminum nitride ceramic substrate and improve the flatness of the substrate. The thermal conductivity of the substrate produced by the method of the invention can be stably controlled above 170W / m·K, and the pass rate of the flatness of the substrate is above 95%.

Owner:银川艾森达新材料发展有限公司

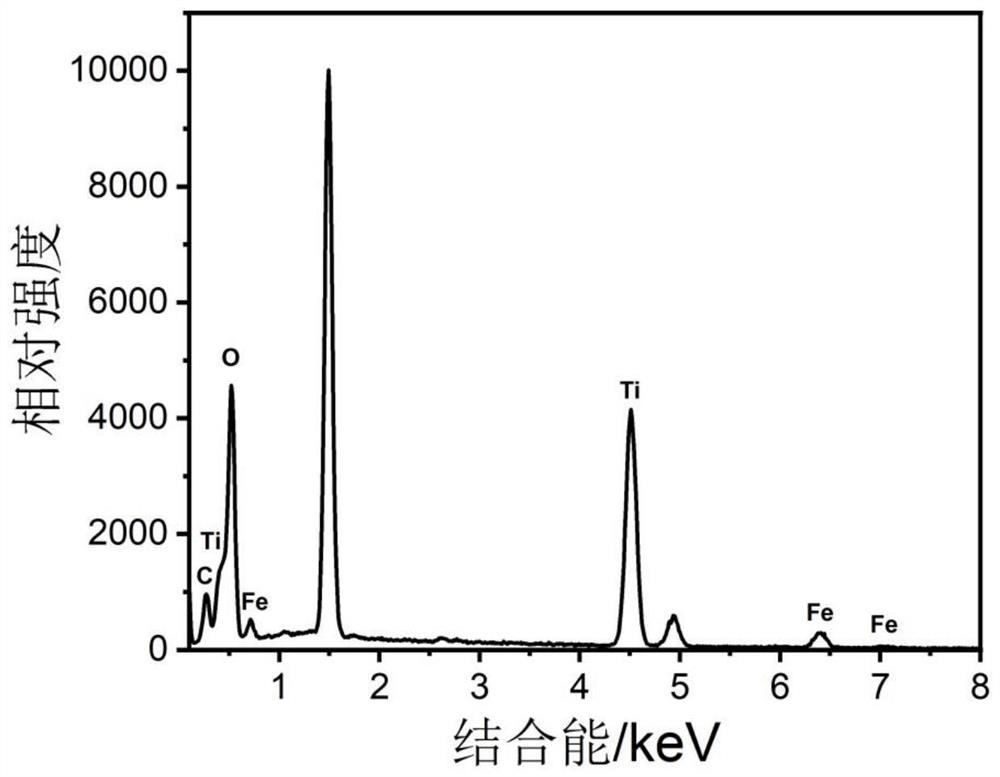

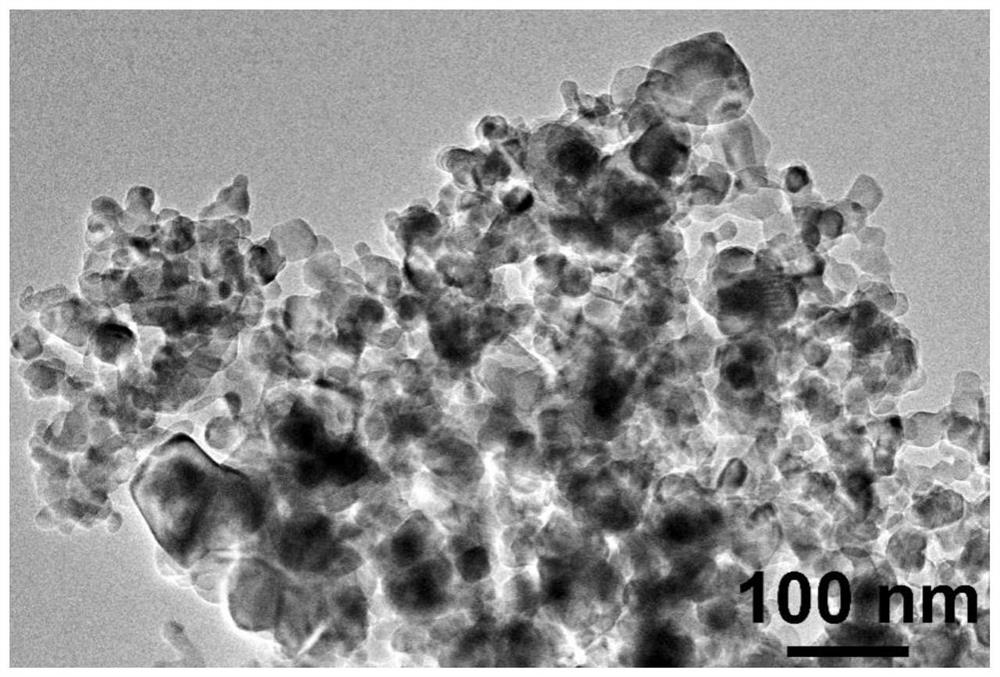

Heat conduction-wave absorption integrated material as well as preparation method and application thereof

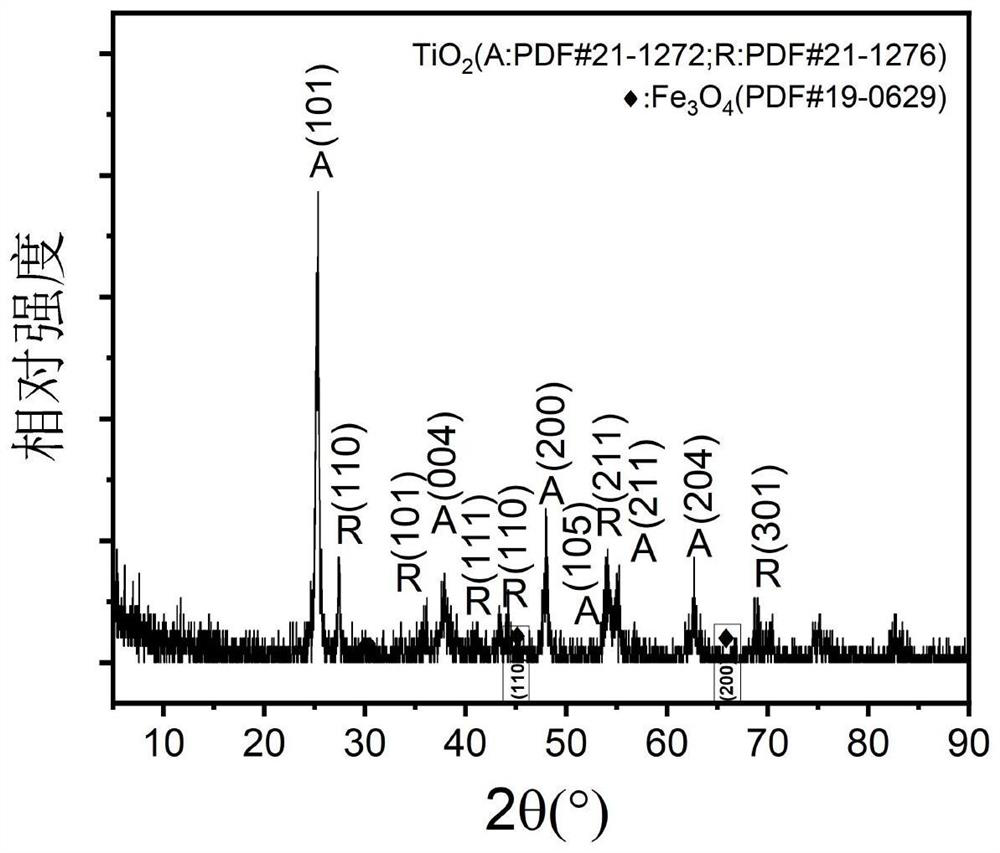

ActiveCN114806424AControl thermal conductivityThe preparation process is simple and controllableNon-macromolecular adhesive additivesMagnetic/electric field screeningSilicone oilPrepared Material

The invention belongs to the technical field of heat conduction-microwave absorption, and discloses a heat conduction-microwave absorption integrated material as well as a preparation method and application thereof. According to the invention, a carbon and iron coated heat conduction-electrical insulation type nano material is used as a filler, a silicone oil matrix is filled with the filler according to a certain proportion, and a release paper tabletting and curing film-forming process is adopted to prepare the heat conduction-wave absorption integrated material; the preparation process is simple and controllable, and the heat-conducting and wave-absorbing properties can be regulated and controlled by changing the proportion of the filler to the silicone oil in the preparation process and the proportion of the carbon, the iron and the heat-conducting-electric insulation type nano material. The prepared material is excellent in heat conduction and wave absorption performance, the problems that a traditional separated heat conduction and wave absorption plate is large in thickness, high in cost, poor in heat conduction and wave absorption performance, complex in process and the like are solved, and the good industrial application potential is achieved.

Owner:ZHEJIANG NORMAL UNIVERSITY

A kind of thermally conductive polybutylene succinate ionomer and its preparation method and application

The invention belongs to the technical field of polymer materials, and discloses a thermally-conductive polybutylene succinate ionomer and a preparation method and application thereof. The preparationmethod comprises the following steps that under an inert atmosphere, succinic acid and butanediol are mixed, stirred and heated for a reaction, a catalyst is added, during vacuuming, the temperatureis increased to 200-220 DEG C for a reaction of 0.5-2.5 hours, and a polybutylene succinate prepolymer is obtained; then the temperature is decreased to 135-155 DEG C, an ionic monomer is added, and vacuuming is conducted for a reaction of 1.5-3.5 hours; finally, nitrogen is introduced, a chain extender is added for a reaction, and after the reaction is completed, cooling is conducted to room temperature to obtain the thermally-conductive polybutylene succinate ionomer. The thermally-conductive polybutylene succinate ionomer is subjected to hot pressing treatment to prepare a sheet-shaped sample strip, then stretching treatment is conducted, and the anisotropic thermally-conductive polybutylene succinate ionomer is prepared.

Owner:SOUTH CHINA UNIV OF TECH

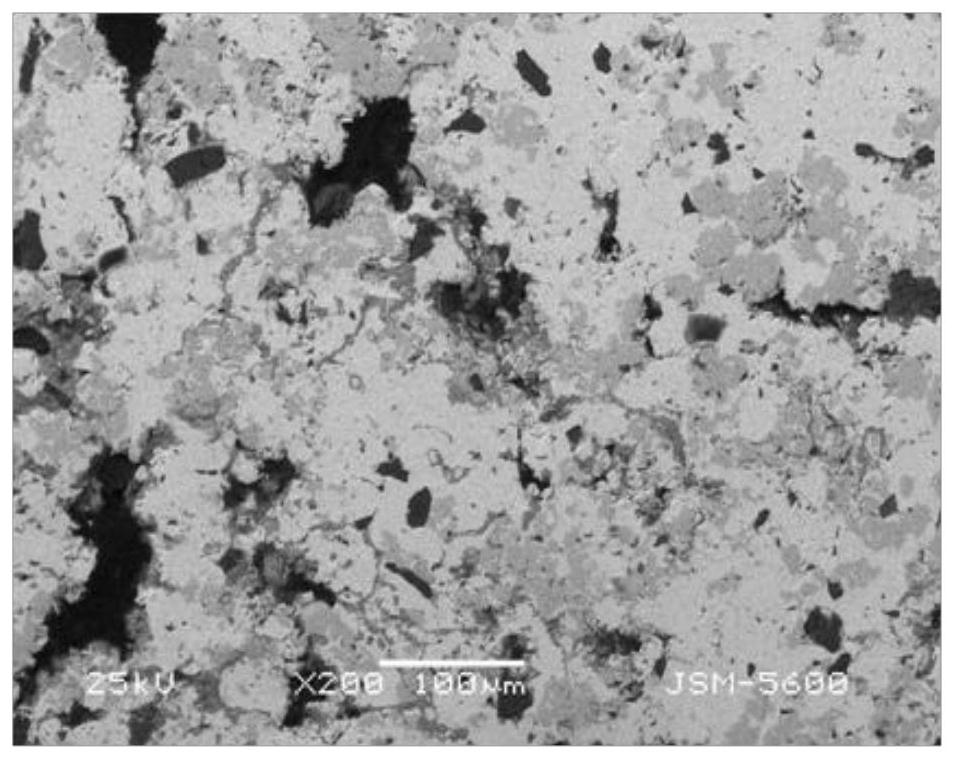

Environment-friendly high-wear-resistance wind power braking friction plate material

An environment-friendly and highly wear-resistant wind-electric brake friction plate material belongs to the technical field of industrial material manufacturing. It uses copper, iron, tin, zircon, graphite and carbon fiber as raw materials, and is made by mixing, cold pressing and sintering. The material of the invention meets the requirements of environmental protection, has stable friction coefficient, long product service life, can well control the density, porosity, thermal conductivity, etc. of the friction material, and is beneficial to reduce the damage of the brake disc and reduce the degree of brake noise.

Owner:CHANGCHUN UNIV OF TECH

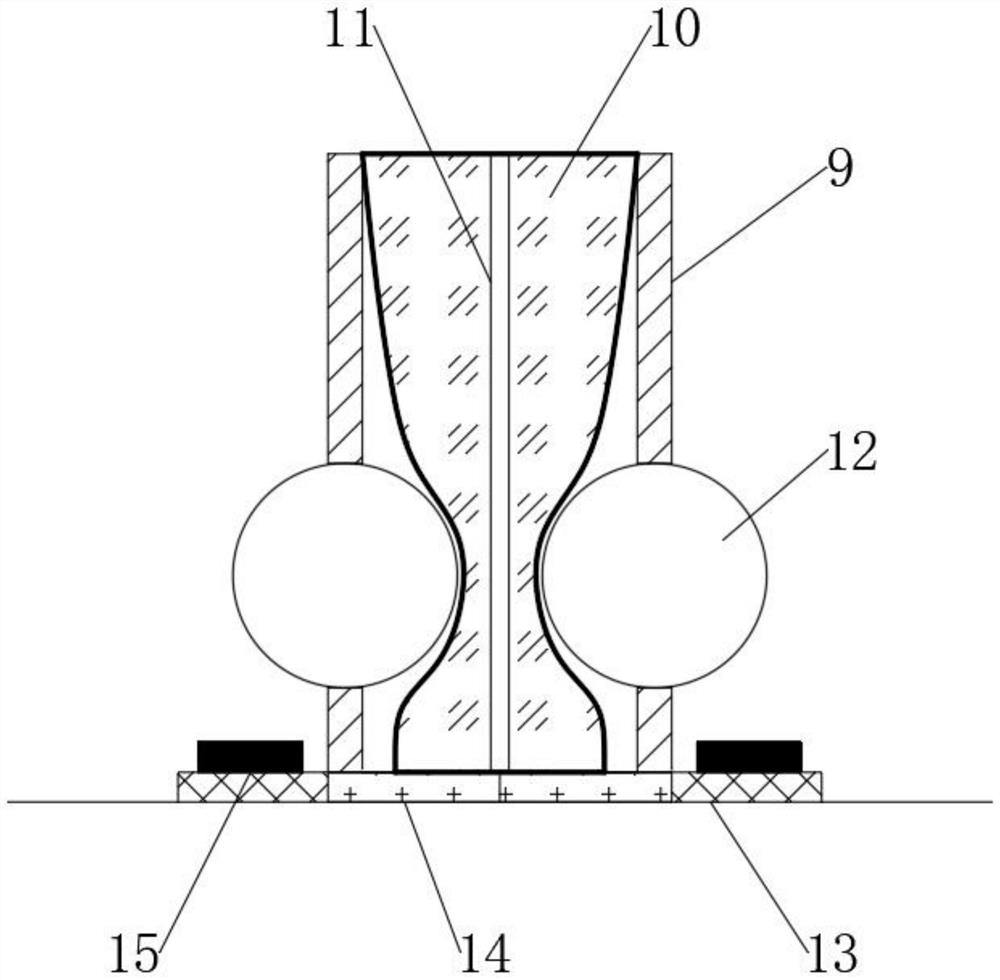

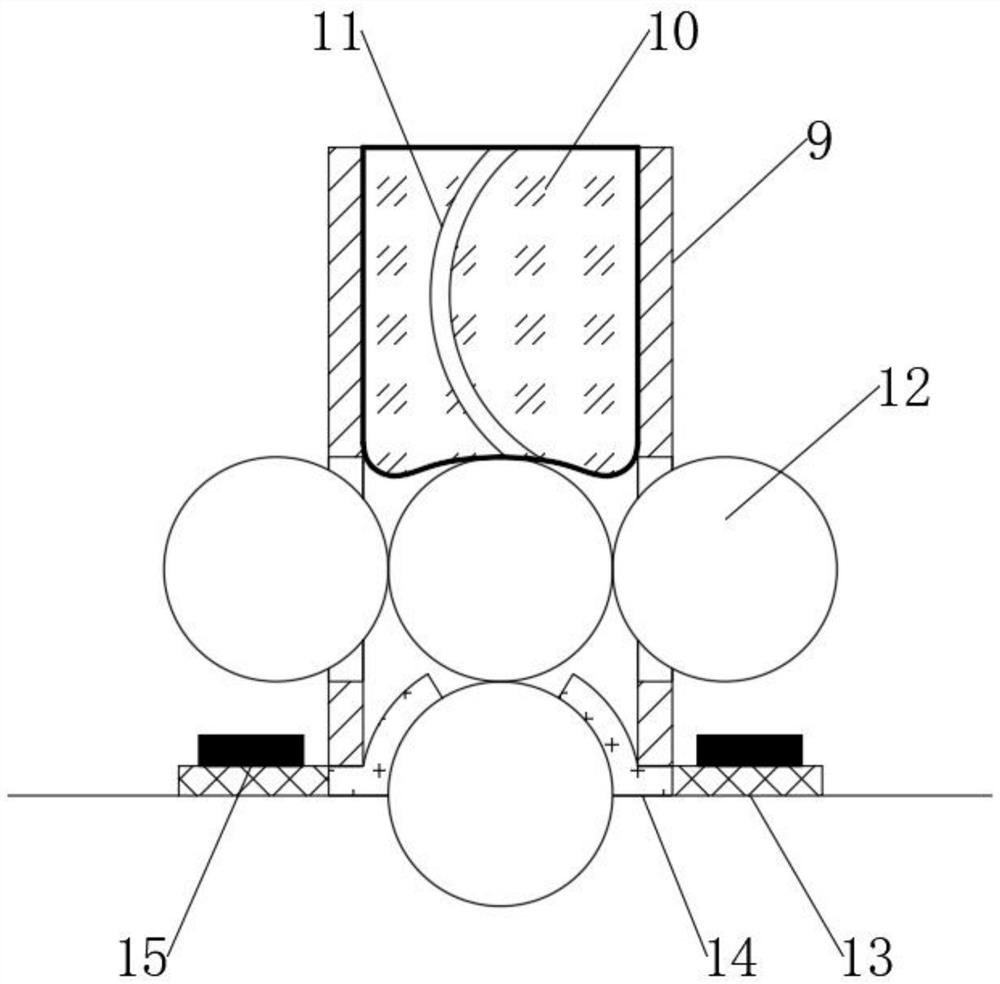

Method for preparing silicon nitride/silicon oxide composite crucible

ActiveCN103803955BImprove thermal conductivityImprove cooling efficiencyPolycrystalline material growthSingle crystal growth detailsCrucibleSilicon oxide

The invention discloses a method for preparing a silicon nitride / silicon oxide composite crucible, relates to a method for preparing a composite crucible, and aims at solving the technical problems that the existing crucible of which the heat conductivity at the bottom is higher than that of the lateral wall is high in production cost and low in production success rate. The method for preparing the silicon nitride / silicon oxide composite crucible disclosed by the invention comprises the following steps: pulping, casting, degerming and sintering at a high temperature. By adopting the silicon nitride / silicon oxide composite crucible disclosed by the invention, the heating efficiency and the cooling efficiency can be improved, and the directional solidification effect of silicon melt is greatly improved. Thus, the growth quality of the silicon crystal is improved, and the cost of photovoltaic power generation of the crystal can be reduced. The method is mainly applied to directional solidification growth of polycrystalline silicon.

Owner:HARBIN INST OF TECH

A light-weight thermal insulation material containing silica micropowder

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com