Router upper and lower cover injection mold and injection molding process thereof

A technology for injection molds and routers, which is used in household appliances, other household appliances, household components, etc., can solve the problems of low processing efficiency, reduced shell appearance quality, and large temperature interference, and achieves full elastic deformation ability and good thermal conductivity. , the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

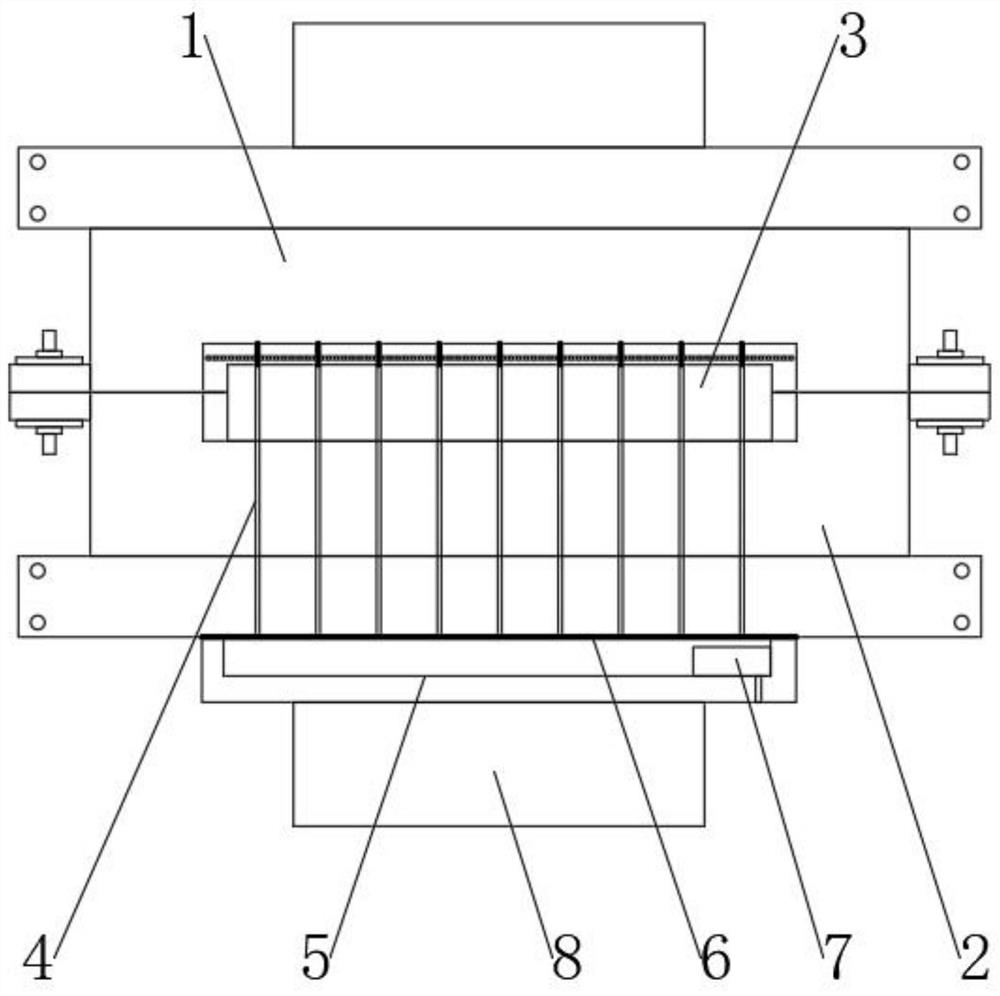

[0045] see figure 1 , an injection mold for the upper and lower covers of the router, including an upper template 1 and a lower template 2, a core 3 is connected to the upper end of the lower template 2, and a plurality of uniformly distributed temperature control columns are connected between the upper template 1 and the core 3, and the upper part of the core 3 A ball injection hole 4 matching the temperature control column is provided, and the ball injection hole 4 runs through the lower formwork 2 and extends to its lower side. The ball injection hole 4 is filled with a plurality of pore-forming balls 12, and the lower end of the lower formwork 2 is connected with a Air pressure seat 5, the upper end of air pressure seat 5 is connected with anti-falling net 6, positive and negative suction fan 7 is installed in the air pressure seat 5, electromagnet 8 is all installed on the upper template 1 and the air pressure seat 5 lower ends.

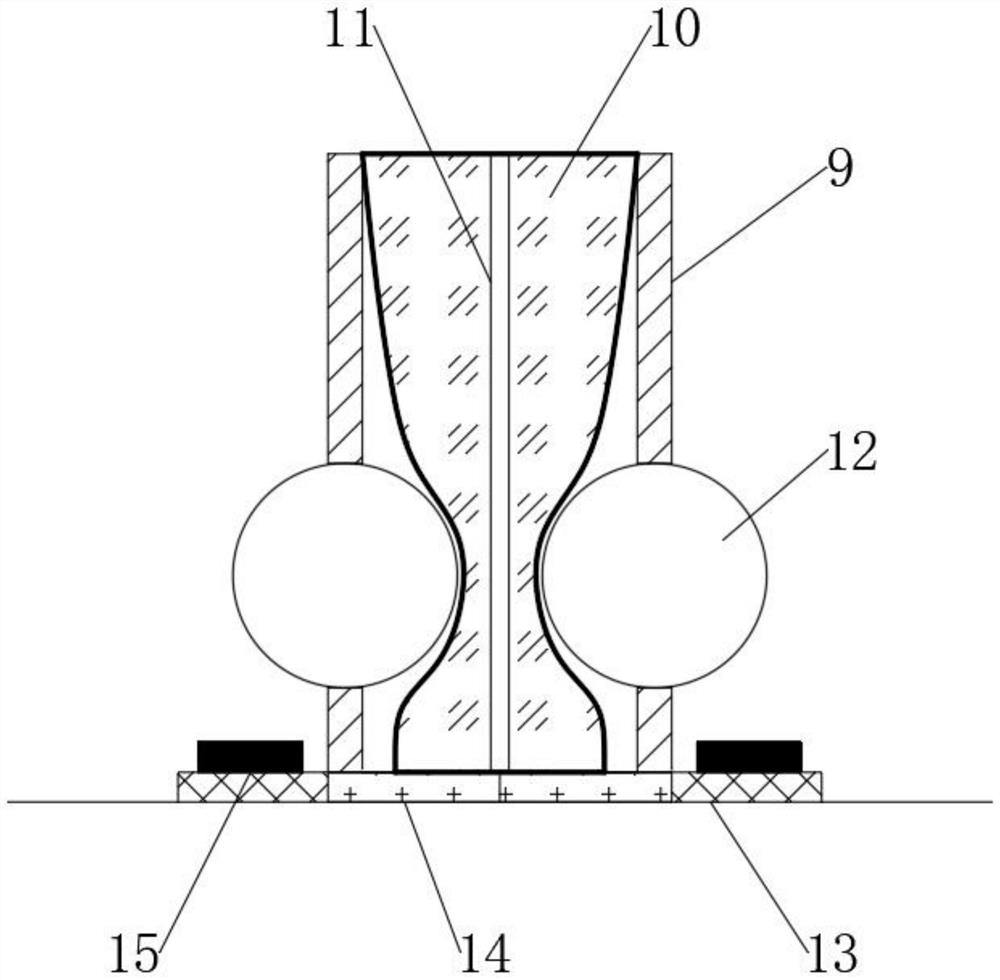

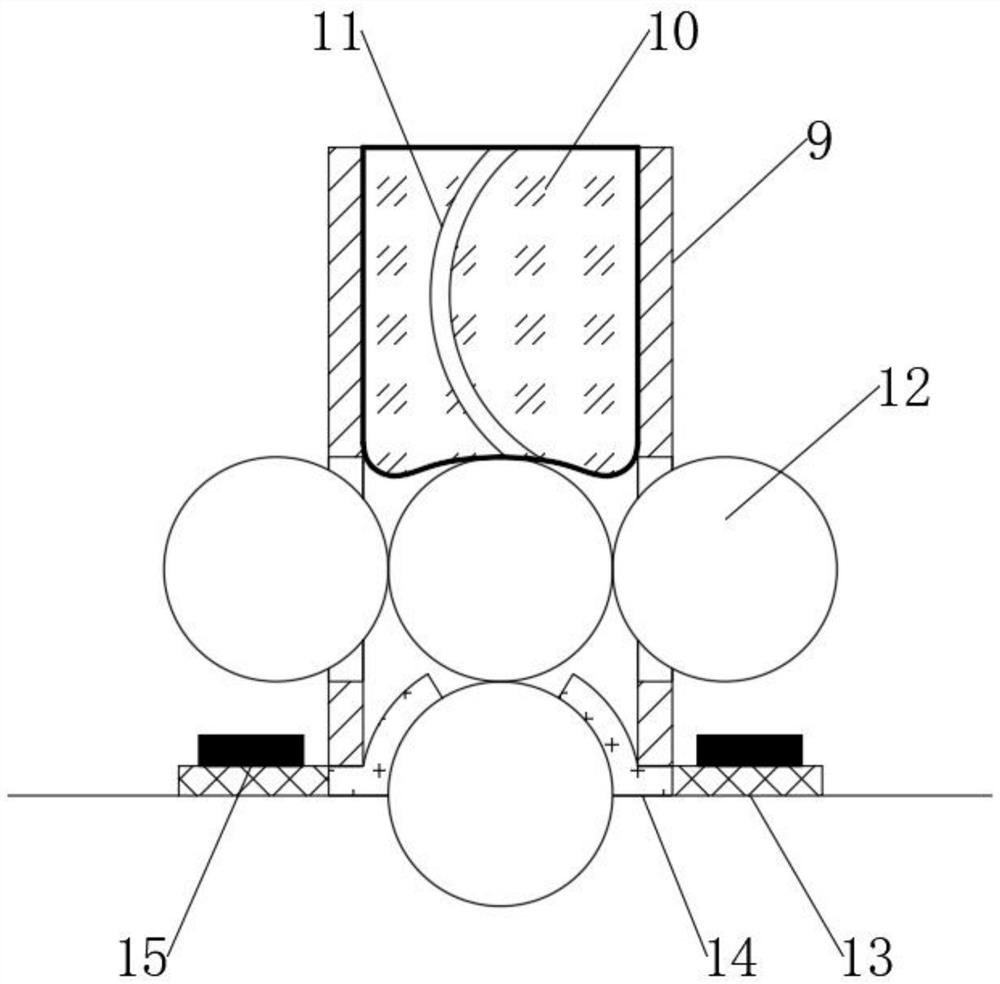

[0046] see Figure 2-3 , the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com